Method for modifying function gelatin

A technology for modifying gelatin, which is applied in the field of functional gelatin modification, which can solve the problems of gelatin becoming brittle and unfavorable for capsule storage and transportation, and achieve the effects of controllable hydrolysis degree, long-term preservation, and abundant raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The method for functional gelatin modification, it comprises the following steps:

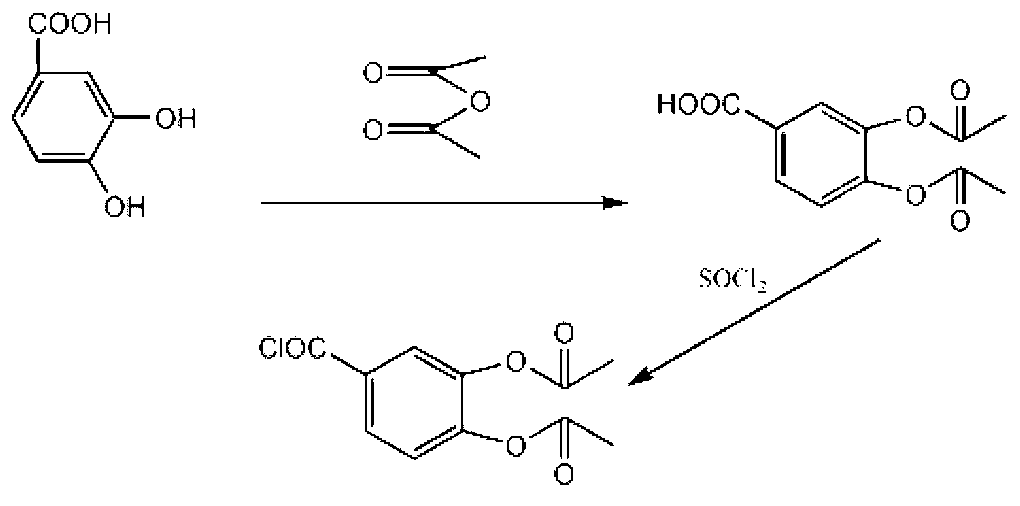

[0037] 1) Hydroxyl protection of 3,4-dihydroxybenzoic acid: Take a 250mL round bottom flask, add 50g of 3,4-dihydroxybenzoic acid and 150mL of acetone, put it in a water bath at 40°C and stir until dissolved, then add acetic anhydride 60mL, reflux reaction at 60°C for 3h, after the reaction is complete, distill and separate the solvent acetone at 65°C, the obtained product is taken out and dried for use;

[0038] 2) Acyl chloride of 3,4-dihydroxybenzoic acid: Take a 250mL round-bottomed flask, add the product in step 1), stir and disperse with 180mL chloroform for 1h, add 23.5mL of thionyl chloride, and reflux at 65°C for 3h , the tail gas is absorbed with an appropriate amount of NaOH solution. After the reaction is complete, the solvent chloroform is separated by distillation at 70°C. The obtained product is taken out, dried, and ground into powder for use;

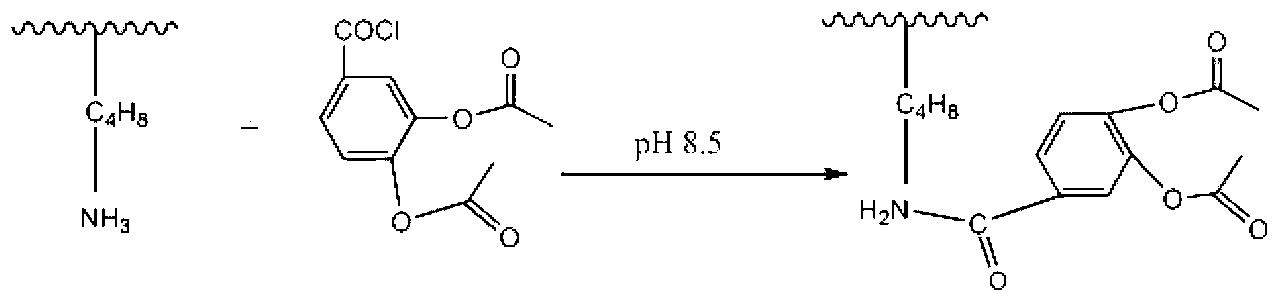

[0039] 3) Modification of...

Embodiment 2

[0042] The method for functional gelatin modification, it comprises the following steps:

[0043] 1) Hydroxyl protection of 3,4-dihydroxybenzoic acid: take a 250mL round bottom flask, add 50g of 3,4-dihydroxybenzoic acid and 180mL of acetone, put it in a water bath at 40°C and stir until dissolved, then add acetic anhydride 90mL, reflux reaction at 65°C for 6h, after the reflux reaction is completed, distill and separate the solvent acetone at 70°C, the obtained product is taken out and dried for use;

[0044] 2) Acyl chloride of 3,4-dihydroxybenzoic acid: Take a 250mL round-bottomed flask, add the product in step 1), stir and disperse with 150mL chloroform for 2h, add 35mL of thionyl chloride, reflux at 70°C for 6h, The tail gas is absorbed with an appropriate amount of NaOH solution. After the reflux reaction is completed, the solvent chloroform is separated by distillation at 75°C. The obtained product is taken out, dried, and ground into powder for use;

[0045] 3) Modifi...

Embodiment 3

[0048] The method for functional gelatin modification, it comprises the following steps:

[0049] 1) Hydroxyl protection of 3,4-dihydroxybenzoic acid: Take a 250mL round bottom flask, add 50g of 3,4-dihydroxybenzoic acid and 160mL of acetone, put it in a water bath at 40°C and stir until dissolved, then add acetic anhydride 75mL, reflux reaction at 70°C for 4h, after the reflux reaction is completed, the solvent acetone is separated by distillation at 60°C, and the obtained product is taken out and dried for use;

[0050] 2) Acyl chloride of 3,4-dihydroxybenzoic acid: take a 250mL round bottom flask, add the product in step 1), stir and disperse with 150mL chloroform for 1.5h, add thionyl chloride 30mL, reflux at 75°C for 5h , the tail gas is absorbed with an appropriate amount of NaOH solution. After the reflux reaction is completed, the solvent chloroform is separated by distillation at 65°C. The obtained product is taken out, dried, and ground into powder for use;

[0051]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com