Tension system control device and method of sheet extruding unit

A technology of extruder unit and tension system, applied in the field of tension system control device of sheet extruder unit, can solve the problems of inability to achieve high-performance control, difficulty in obtaining better sheet quality, and difficulty in maintaining constant tension, etc. The effect of improving tension control accuracy, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

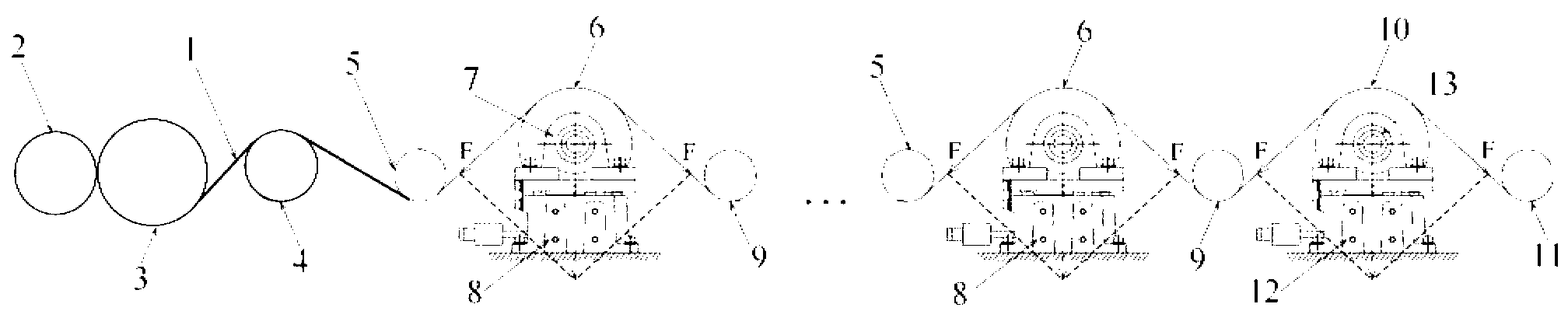

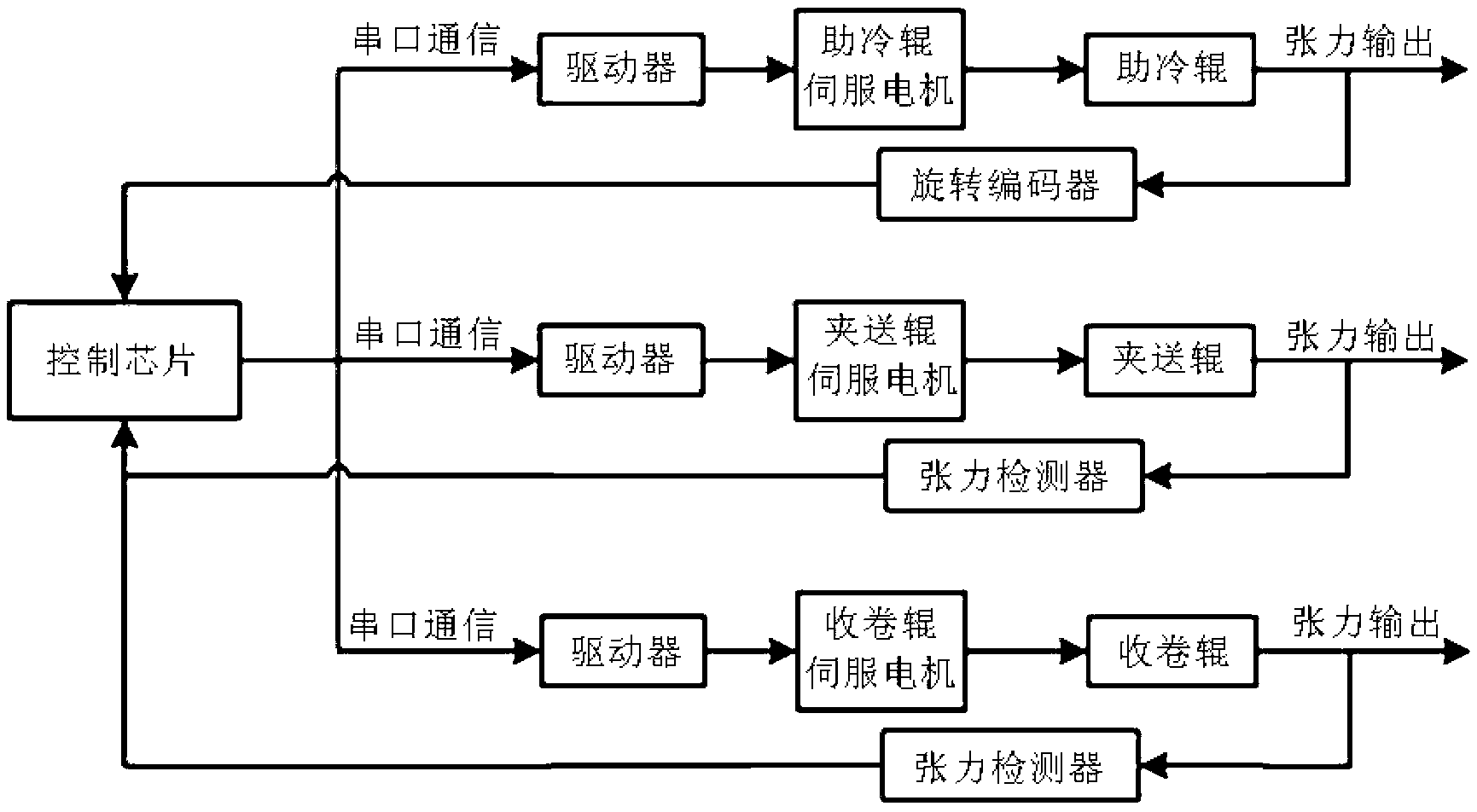

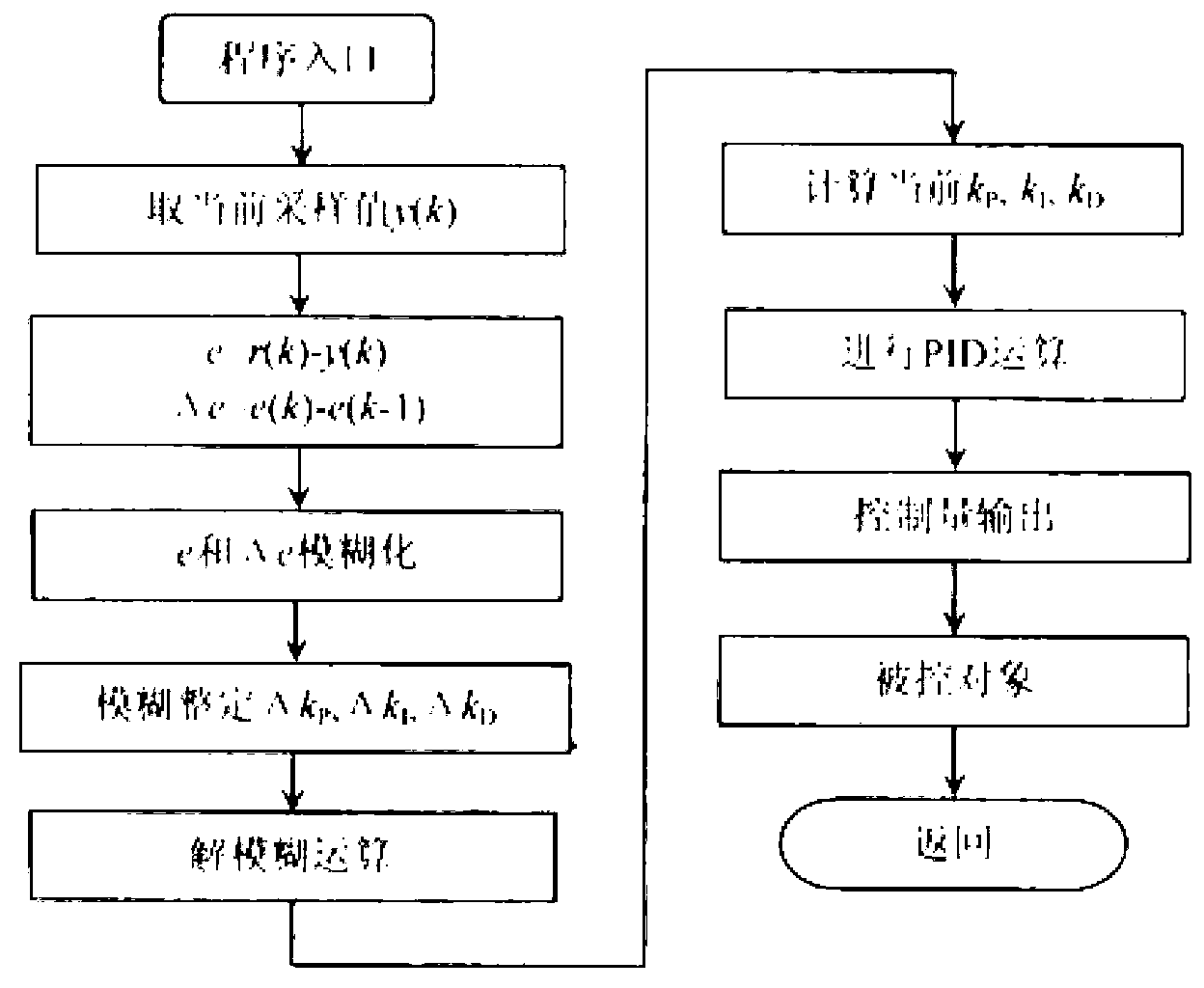

[0045] see figure 1 , the sheet extruder tension system control device provided by the present invention includes the sheet 1 extruded by the first extrusion roller 2 and the second extrusion roller 3, and the auxiliary cooling rollers arranged in sequence along the moving direction of the sheet are controlled system, a pinch roll control system and a winding roll control system, and a control chip with a fuzzy PID controller and a PID controller. Wherein, the second squeezing roller is provided with a squeezing roller position sensor. The chilling roll control system includes a chilling roll 4, a chilling roll servo motor and a position sensor are arranged on the chilling roll, and a first rotary encoder and a driver of the chilling roll servo motor are connected to the chilling roll servo motor. The pinch roller control system includes a pinch roller 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com