Cooper base catalyst and preparation method thereof

A copper-based catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve problems such as single component and poor reaction stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Weigh 0.87g of metal copper powder, 5.44g of cuprous chloride, 3.69g of anhydrous cupric chloride and 0.4g of brass powder as the reaction raw materials, and mix well to obtain Cu-CuCl-CuCl 2Novel copper-based catalyst; the composition of the resulting novel copper-based catalyst is 8.7% Cu, 54.4% CuCl and 36.9% CuCl 2 .

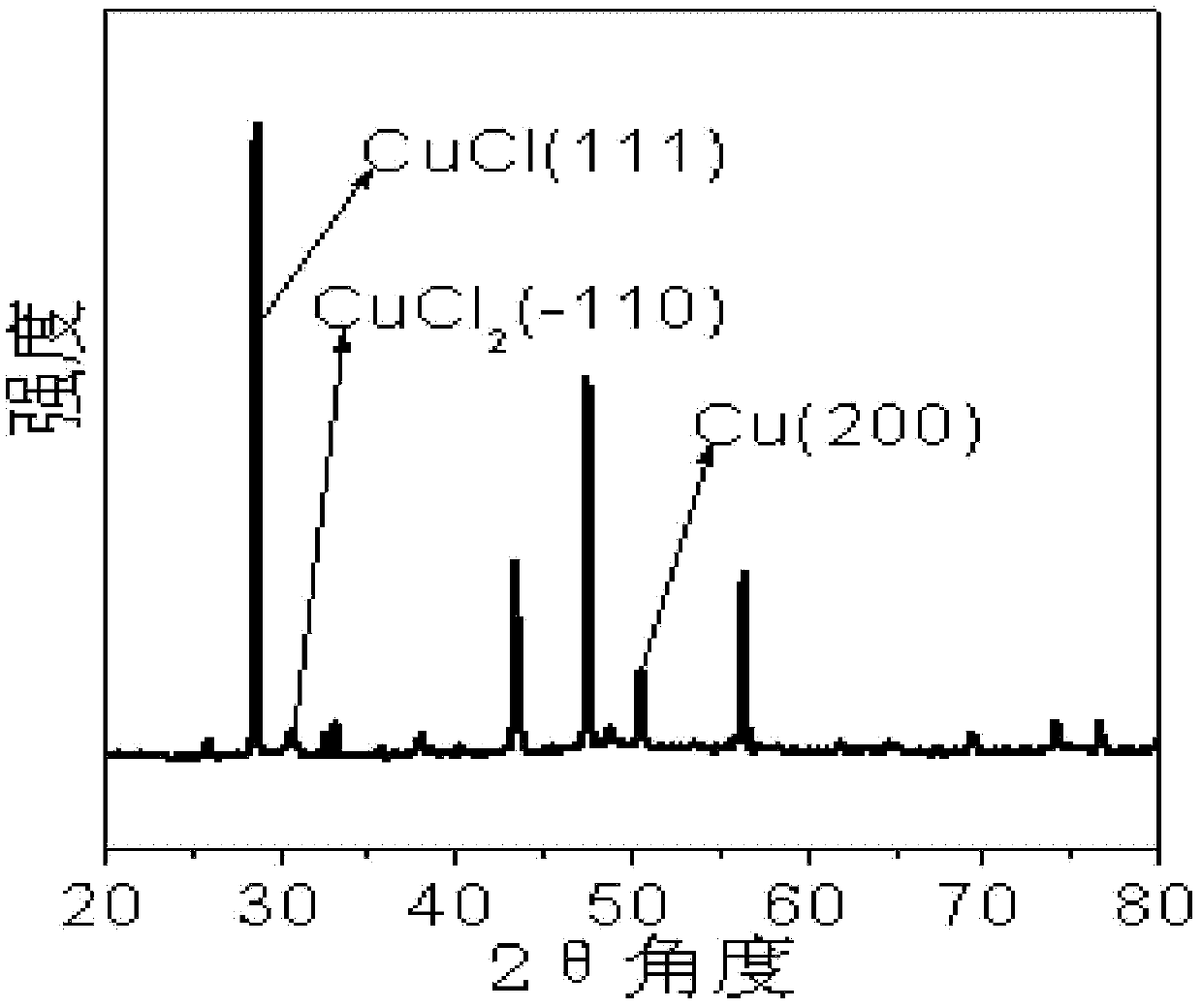

[0069] The prepared catalyst material was subjected to XRD test on an X'PertPRO MPD multifunctional X-ray diffractometer produced by Panalytical Company (Panalytical) in the Netherlands.

[0070] figure 1 It is the XRD figure of the copper-based catalyst that embodiment 1 obtains, wherein 2θ=28.6 ° is the characteristic peak of CuCl, 2θ=30.8 ° and 2θ=38.1 ° are CuCl 2 The characteristic peaks of 2θ=43.3° and 2θ=50.4° are the characteristic peaks of Cu. It can be seen that the copper-based catalyst prepared by this method is composed of Cu, CuCl and CuCl 2 composition.

Embodiment 2

[0072] Weigh 1.02g of metal copper powder, 2.57g of copper oxide, 6.41g of cuprous chloride and 0.40g of brass powder as the reaction raw materials, mix them evenly, and dry ball mill them in a stirring ball mill for 4 hours; after separation, drying and sieving, A Cu-CuCl-CuO type copper-based catalyst is obtained; the composition of the obtained copper catalyst is: 10.2% Cu, 64.1% CuCl and 25.7% CuO.

[0073] figure 2 For the XRD pattern of the copper-based catalyst obtained in Example 2, wherein 2θ=28.6° is the characteristic peak of CuCl, the shoulder peak composed of 2θ=35.5° and 2θ=38.8° is the characteristic peak of CuO, 2θ=43.3° and 2θ =50.4° is the characteristic peak of Cu, thus it can be seen that the copper-based catalyst prepared by this method is composed of Cu, CuCl and CuO.

Embodiment 3

[0075] Weigh a commercial CuO 0.52 Catalyst 8.00g and cuprous chloride 2.00g are reaction raw materials, carry out thorough mixing on sand mill, obtain Cu-Cu 2 O-CuO-CuCl new copper-based catalyst; the obtained copper catalyst formula is Cu-Cu 2 The composition distribution of O-CuO composition and CuCl is: 80% and 20%, respectively.

[0076] image 3 It is the XRD figure of the copper-based catalyst that embodiment 3 obtains, and wherein 2θ=28.6 ° is the characteristic peak of CuCl, and 2θ=36.5 ° is Cu 2 The characteristic peak of O, the shoulder peak that is made up of 2θ=35.5 ° and 2θ=38.8 ° is the characteristic peak of CuO, 2θ=43.3 ° is the characteristic peak of Cu, thus it can be seen that the copper-based catalyst prepared by this method is composed of Cu, Cu 2 O and CuO composition together with CuCl.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com