Nano-array structured catalyst used for Fischer-Tropsch synthesis and preparation method and application thereof

A structured catalyst and nano-array technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, liquid hydrocarbon mixtures, etc., can solve the problem of poor carrier bonding, easy sintering, Uneven distribution of active components, etc., to avoid leaching loss, easy processability, and excellent mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

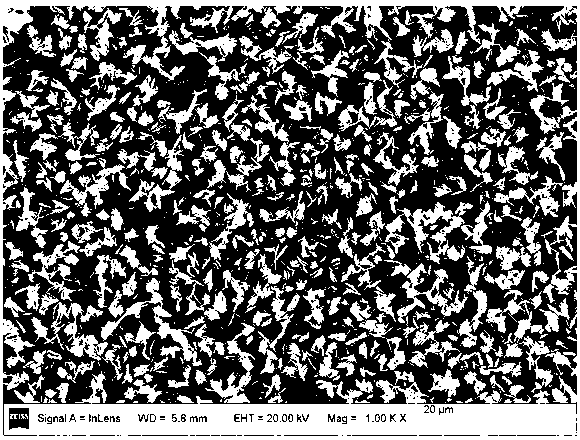

[0026] The galvanized iron substrate (108cm 2 ) with 0.5 mol L -1Ultrasonic cleaning with hydrochloric acid for 10 minutes, then ultrasonic cleaning with absolute ethanol for 10 minutes, and then cleaning with deionized water to obtain a substrate for later use; dissolving ferric nitrate, ammonium fluoride and hexamethylenetetramine in deionized water to form a solution, wherein The concentration of iron ions is 0.1 mol L -1 , the concentration of ammonium fluoride is 0.2 mol L -1 , the concentration of hexamethylenetetramine is 0.1 mol L -1 Immerse the cleaned galvanized iron substrate obtained above into the obtained mixed solution, and heat it in a reaction kettle at 80°C for 24 hours, and cool it down to room temperature naturally after the reaction; the obtained substrate is washed with absolute ethanol and water to remove impurities, and heated at 40°C Dry in an oven for 6 hours; then bake in a muffle furnace at 300°C for 6 hours to obtain a nano-array structured cata...

Embodiment 2

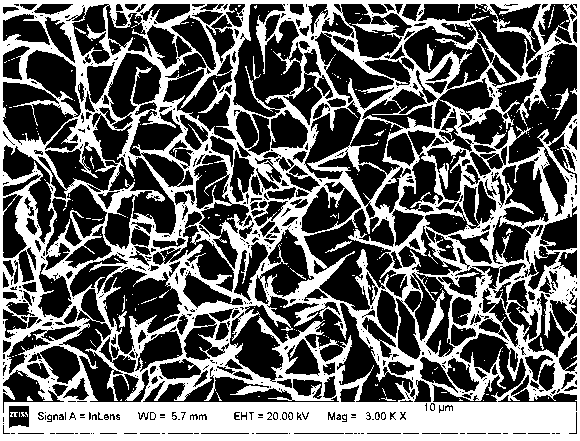

[0028] The galvanized iron substrate (96cm 2 ) with 1 mol·L -1 Ultrasonic cleaning with hydrochloric acid for 8 minutes, then ultrasonic cleaning with absolute ethanol for 10 minutes, and then cleaning with deionized water to obtain a substrate for later use; dissolving ferric nitrate, sodium fluoride and urea in deionized water to form a solution, wherein the concentration of iron ions is 0.3 mol·L -1 , the concentration of sodium fluoride is 0.5 mol L -1 , the concentration of urea is 0.5 mol L -1 Immerse the cleaned galvanized iron substrate obtained above into the obtained mixed solution, and heat it in a reaction kettle at 100°C for 18 hours, and cool it down to room temperature naturally after the reaction; the obtained substrate is washed with absolute ethanol and water to remove impurities, and heated at 50°C Dry in an oven for 5 hours; then bake in a muffle furnace at 400°C for 2 hours to obtain a nano-array structured catalyst. The mass of the active component of ...

Embodiment 3

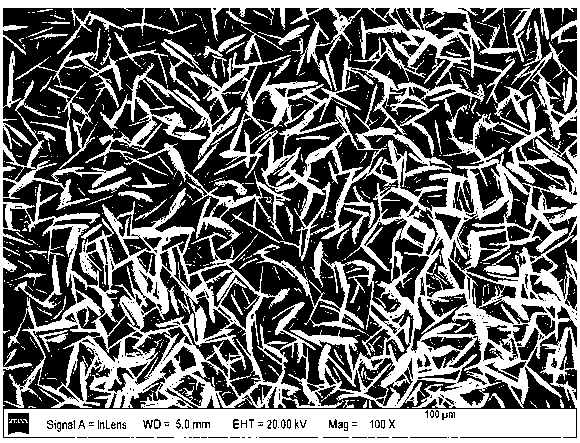

[0030] The stainless steel substrate (72 cm 2 ) with 1.5 mol L -1 Ultrasonic cleaning with hydrochloric acid for 7 minutes, then ultrasonic cleaning with absolute ethanol for 10 minutes, and then cleaning with deionized water to obtain a matrix for later use; dissolve ferric chloride, sodium thiocyanide and hexamethylenetetramine in deionized water to make a solution , where the concentration of iron ions is 0.2 mol L -1 , the concentration of sodium thiocyanate is 0.6 mol L -1 , the concentration of hexamethylenetetramine is 0.8 mol L -1 ; Immerse the cleaned stainless steel substrate obtained above into the obtained mixed solution, and heat it in a reaction kettle at 120°C for 12 hours, and cool it to room temperature naturally after the reaction; the obtained substrate is washed with absolute ethanol and water respectively to remove impurities, Dry in an oven for 4 hours; then bake in a muffle furnace at 350°C for 3 hours to obtain a nano-array structured catalyst. The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com