Electrode for non-aqueous electrolyte secondary battery, non-aqueous electrolyte secondary battery, and method for manufacturing the same

A non-aqueous electrolyte and secondary battery technology, which is applied in the direction of non-aqueous electrolyte battery electrodes, electrolyte battery manufacturing, non-aqueous electrolyte batteries, etc., to achieve excellent load characteristics and excellent charge-discharge cycle characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0021] First, the electrode for a nonaqueous electrolyte secondary battery and the nonaqueous electrolyte secondary battery of the present invention will be described.

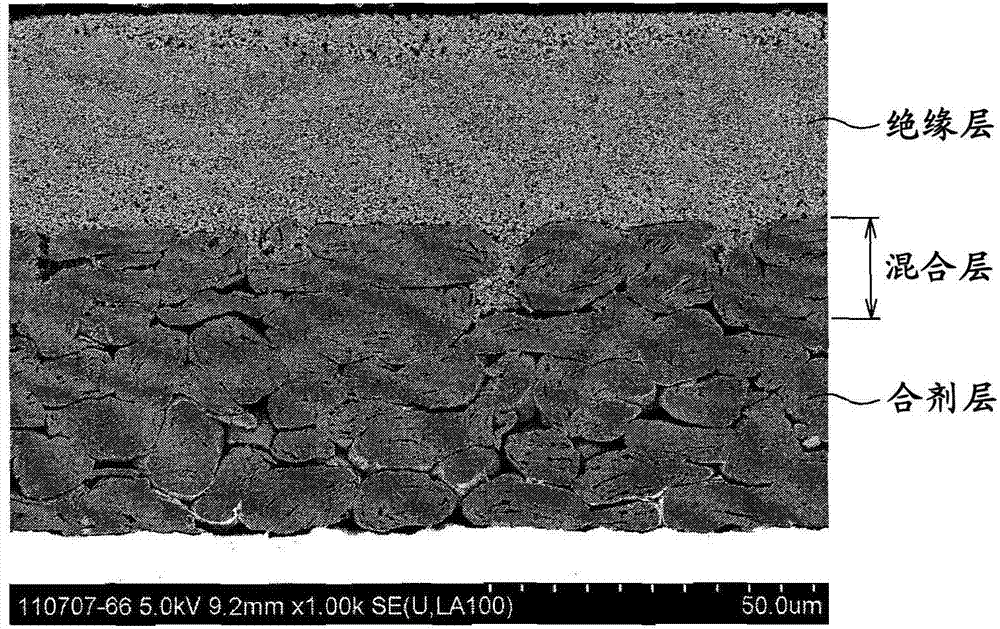

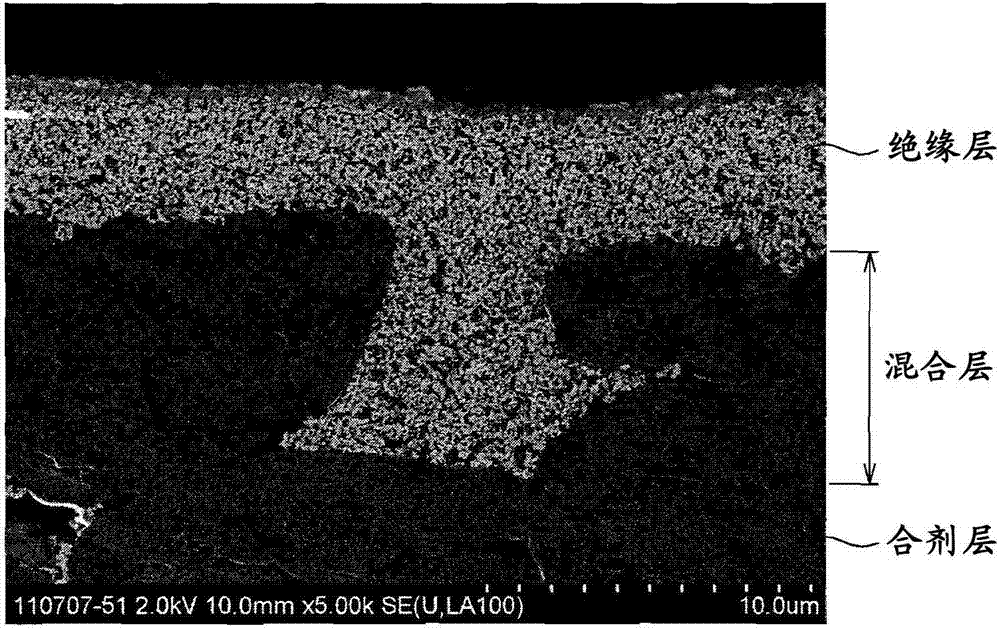

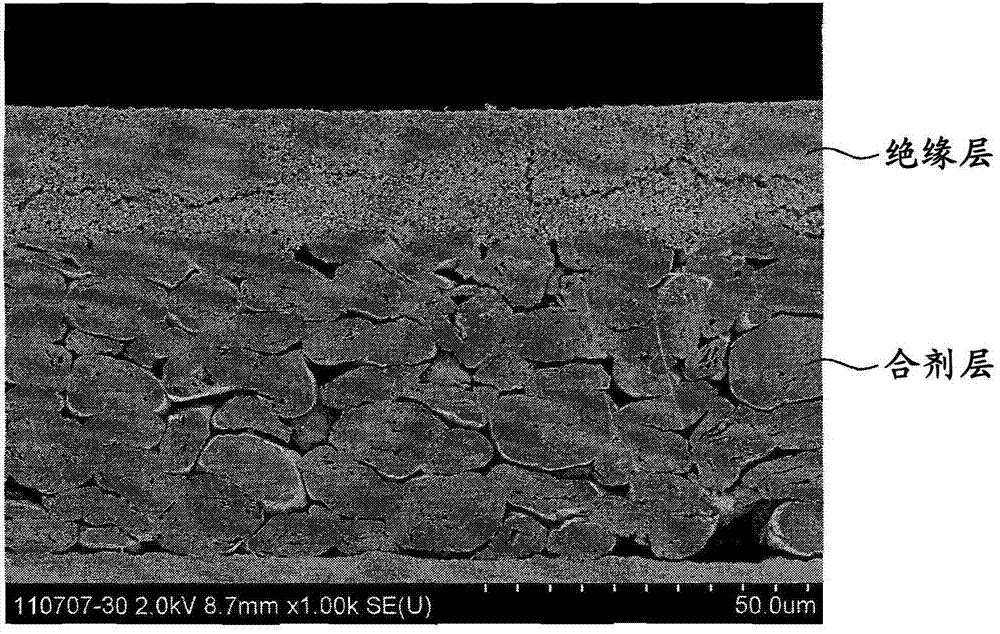

[0022] The electrode for a nonaqueous electrolyte secondary battery of the present invention is an electrode for a nonaqueous electrolyte secondary battery comprising a mixture layer containing an active material and a porous insulating layer, wherein the insulating layer is formed on the mixture layer, and the The insulating layer includes a resin having a crosslinked structure and inorganic particles, and has a mixed layer containing components of the insulating layer and components of the mixture layer at an interface between the insulating layer and the mixture layer.

[0023] The first aspect of the non-aqueous electrolyte secondary battery of the present invention is characterized in that it comprises a positive electrode having a material mixture layer containing a positive electrode active material, a n...

Embodiment approach 2

[0103] Next, a method for manufacturing the nonaqueous electrolyte secondary battery of the present invention will be described.

[0104] The 1st form of the manufacture method of the nonaqueous electrolyte secondary battery of the present invention is to have the positive electrode that has the mixture layer that contains positive electrode active material, the negative electrode that has the mixture layer that contains negative electrode active material, insulating layer and nonaqueous electrolyte. A method for producing an electrolyte secondary battery, comprising the step of producing an insulating layer-forming composition comprising oligomers and monomers capable of being polymerized by irradiation with energy rays, inorganic particles, a hot-melt resin, and a solvent the step of forming a coating film by applying the composition for forming an insulating layer on the mixture layer of at least one electrode selected from the positive electrode and the negative electrode; ...

Embodiment 1)

[0125]

[0126] The following materials were added to the container in the following proportions, and stirred for 12 hours to prepare a mixed solution.

[0127] (1) Boehmite (inorganic particles, average particle size: 0.6 μm): 21.10 parts by mass

[0128] (2) Polyethylene microparticles (hot-melt resin particles, melting point: 120°C): 3.54 parts by mass

[0129] (3) Urethane acrylate (polymerizable oligomer, "EBECRYL8405" manufactured by Daicel-Cytec): 6.26 parts by mass

[0130] (4) Tripropylene glycol diacrylate (polymerizable monomer): 1.56 parts by mass

[0131] (5) Methyl ethyl ketone (low boiling point solvent, boiling point: about 79.6°C, polarity parameter: 4.7): 48.46 parts by mass

[0132] (6) Water: 14.16 parts by mass

[0133] (7) Ethylene glycol (high boiling point solvent, boiling point: about 197.9°C): 4.69 parts by mass

[0134] (8) Zirconia beads (diameter: 1.5mm): 50% of the coating volume

[0135] Next, 0.23 parts by mass of 2,4,6-trimethylbenzoyl-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com