Nonaqueous secondary battery separator and non-aqueous secondary battery

一种二次电池、非水系的技术,应用在非水系二次电池用隔膜及非水系二次电池领域,能够解决循环寿命降低等问题,达到粘接性优异、离子透过性优异、循环特性及负荷特性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0208] 〔Production of diaphragm〕

[0209] As the polyvinylidene fluoride resin A, a vinylidene fluoride / hexafluoropropylene copolymer having a composition ratio (molar ratio) of 99.4 / 0.6 was prepared by suspension polymerization.

[0210] As the polyvinylidene fluoride-based resin B, a vinylidene fluoride / hexafluoropropylene copolymer (weight average molecular weight: 470,000) having a composition ratio (molar ratio) of 95.2 / 4.8 was prepared.

[0211] A polyvinylidene fluoride resin obtained by mixing polyvinylidene fluoride resin A and polyvinylidene fluoride resin B at a mass ratio of 60 / 40 was dissolved in a mixed solvent of dimethylacetamide and tripropylene glycol (dimethyl ethylene glycol) Amide / tripropylene glycol=7 / 3 [mass ratio]), the resin concentration was set to 5% by mass to prepare a coating liquid for forming an adhesive porous layer.

[0212] Apply this coating solution equally to both sides of a polyethylene microporous membrane (film thickness 9 μm, Gurley v...

Embodiment 2

[0224] As the polyvinylidene fluoride resin A, a vinylidene fluoride / hexafluoropropylene copolymer having a composition ratio (molar ratio) of 98.6 / 1.4 was prepared by suspension polymerization.

[0225] A separator of Example 2 was produced in the same manner as in Example 1 except that the above resin was used as the polyvinylidene fluoride-based resin A. Thereafter, a test battery of Example 2 was produced in the same manner as in Example 1.

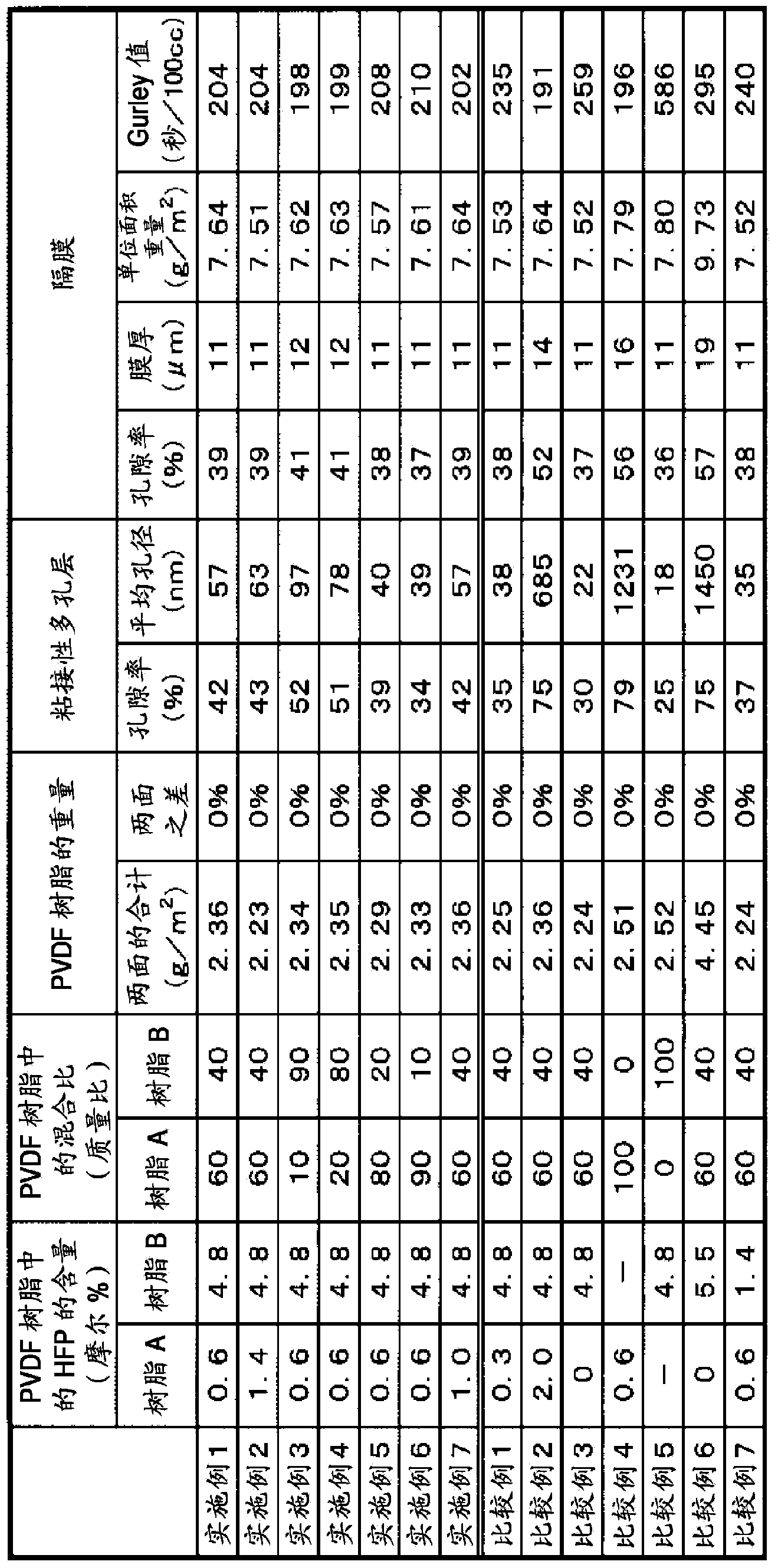

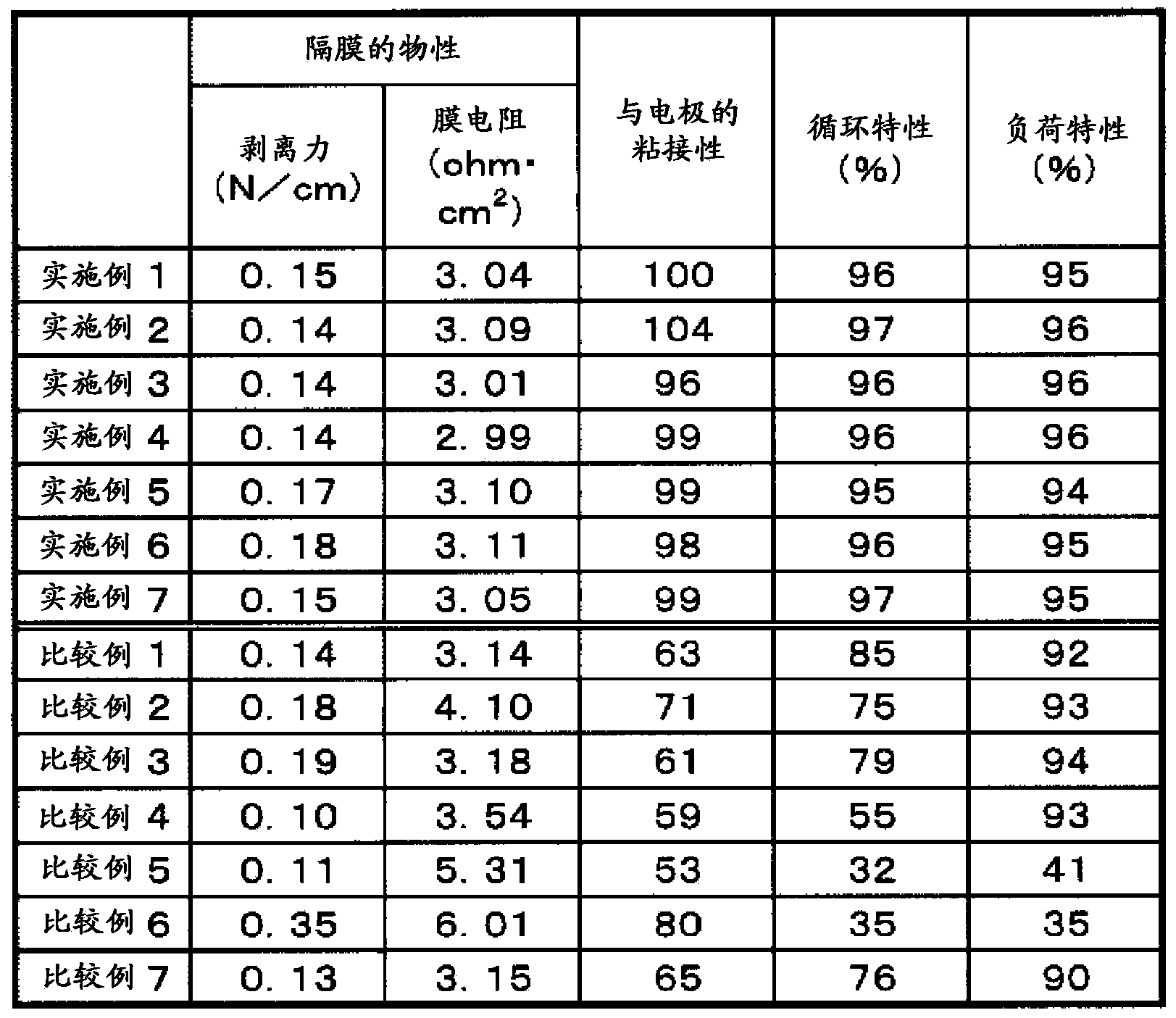

[0226] Table 1 and Table 2 show the physical property values and evaluation results of the separator and test battery of Example 2.

Embodiment 3

[0228] The separator of Example 3 was produced in the same manner as in Example 1 except that the mixing ratio of the polyvinylidene fluoride resin A and the polyvinylidene fluoride resin B was 10 / 90. Thereafter, in the same manner as in Example 1, a test battery of Example 3 was fabricated.

[0229] Table 1 and Table 2 show the physical property values and evaluation results of the separator and test battery of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com