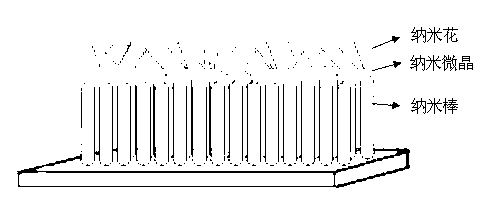

Titanium dioxide nanorod-nanocrystalline-nanoflower material and preparation method thereof

A technology of titanium dioxide and nano-crystals, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of inability to ensure uniform and tight bonding of materials, and difficulty in exerting electron transport performance, so as to improve electron transport performance and cost Low, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Fluorine-doped tin oxide conductive glass of 10mm×10mm was ultrasonically cleaned in ethanol, acetone, and deionized water for 10 minutes, and dried naturally for later use; 3g of titanium dioxide P 25 powder and 1g of ethyl cellulose were added to 10mL of absolute ethanol to prepare Titanium dioxide ethanol solution and ethyl cellulose ethanol solution, after the two are mechanically mixed, add 6g terpineol and 5g n-butanol, 200r min -1 Stir at high speed for 2h. Then carry out a water bath reaction at a temperature of 80°C, evaporate the ethanol, put the prepared colloid into an agate mortar and grind for 10 minutes to obtain a titanium dioxide slurry; fix the treated conductive glass on a screen printing machine, and print Technology Print titanium dioxide slurry on fluorine-doped tin oxide conductive glass, the mesh number of which is 400 mesh, the screen area is 8mm×8mm, the coating thickness is 2μm, and dried under natural conditions for 30min; in a 50mL reaction ...

Embodiment 2

[0021] Fluorine-doped tin oxide conductive glass of 10mm×10mm was ultrasonically cleaned in ethanol, acetone, and deionized water for 10 minutes, and dried naturally for later use; 4g of titanium dioxide P 25 powder and 1g of ethyl cellulose were added to 10mL of absolute ethanol to prepare Titanium dioxide ethanol solution and ethyl cellulose ethanol solution, after the two are mechanically mixed, add 7.5g terpineol and 7g n-butanol, 200r min -1 Stir at high speed for 2h. Then carry out a water bath reaction at a temperature of 80°C, evaporate the ethanol, put the prepared colloid into an agate mortar and grind for 10 minutes to obtain a titanium dioxide slurry; fix the treated conductive glass on a screen printing machine, and print Technology Print titanium dioxide slurry on fluorine-doped tin oxide conductive glass, the mesh number of which is 400 mesh, the screen area is 8mm×8mm, the coating thickness is 2μm, and dried under natural conditions for 30min; in a 50mL reactio...

Embodiment 3

[0023] Fluorine-doped tin oxide conductive glass of 10mm×10mm was ultrasonically cleaned in ethanol, acetone, and deionized water for 10 minutes, and dried naturally for later use; 3g of titanium dioxide P 25 powder and 1g of ethyl cellulose were added to 10mL of absolute ethanol to prepare Titanium dioxide ethanol solution and ethyl cellulose ethanol solution, after the two are mechanically mixed, add 7.5g terpineol and 8g n-butanol, 250r min -1 Stir at high speed for 2h. Then carry out a water bath reaction at a temperature of 85°C, evaporate ethanol, put the prepared colloid into an agate mortar and grind for 10 minutes to obtain a titanium dioxide slurry; fix the treated conductive glass on a screen printing machine, and print Technology Print titanium dioxide slurry on fluorine-doped tin oxide conductive glass, the mesh number of which is 400 mesh, the screen area is 8mm×8mm, the coating thickness is 2μm, and dried under natural conditions for 30min; in a 50mL reaction ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com