Control method and control system for scrap copper smelting furnace based on image analysis

A technology of image analysis and control methods, which is applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve the problems of energy saving, prolonging the time of smelting process, waste of power frequency heating power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

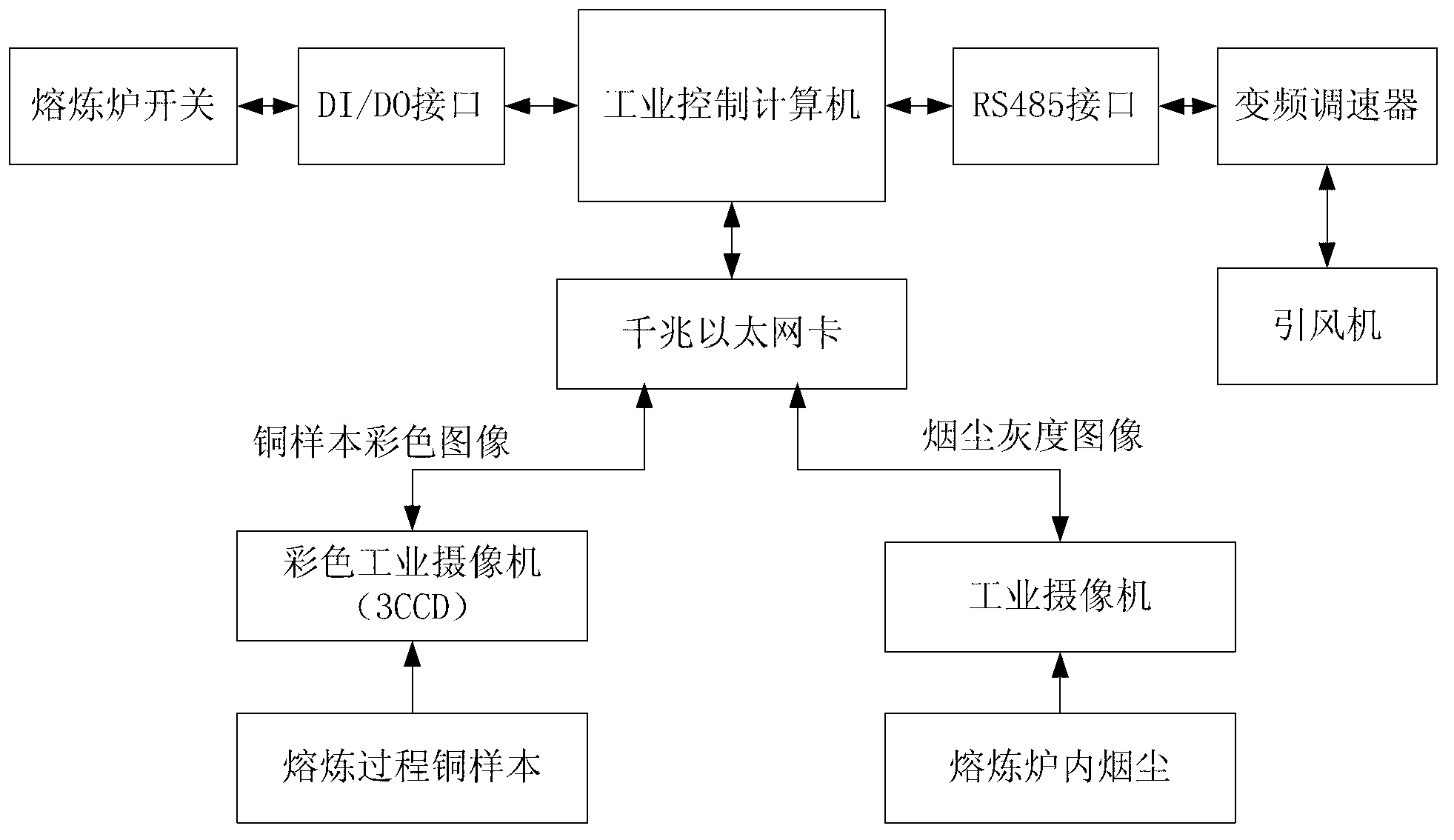

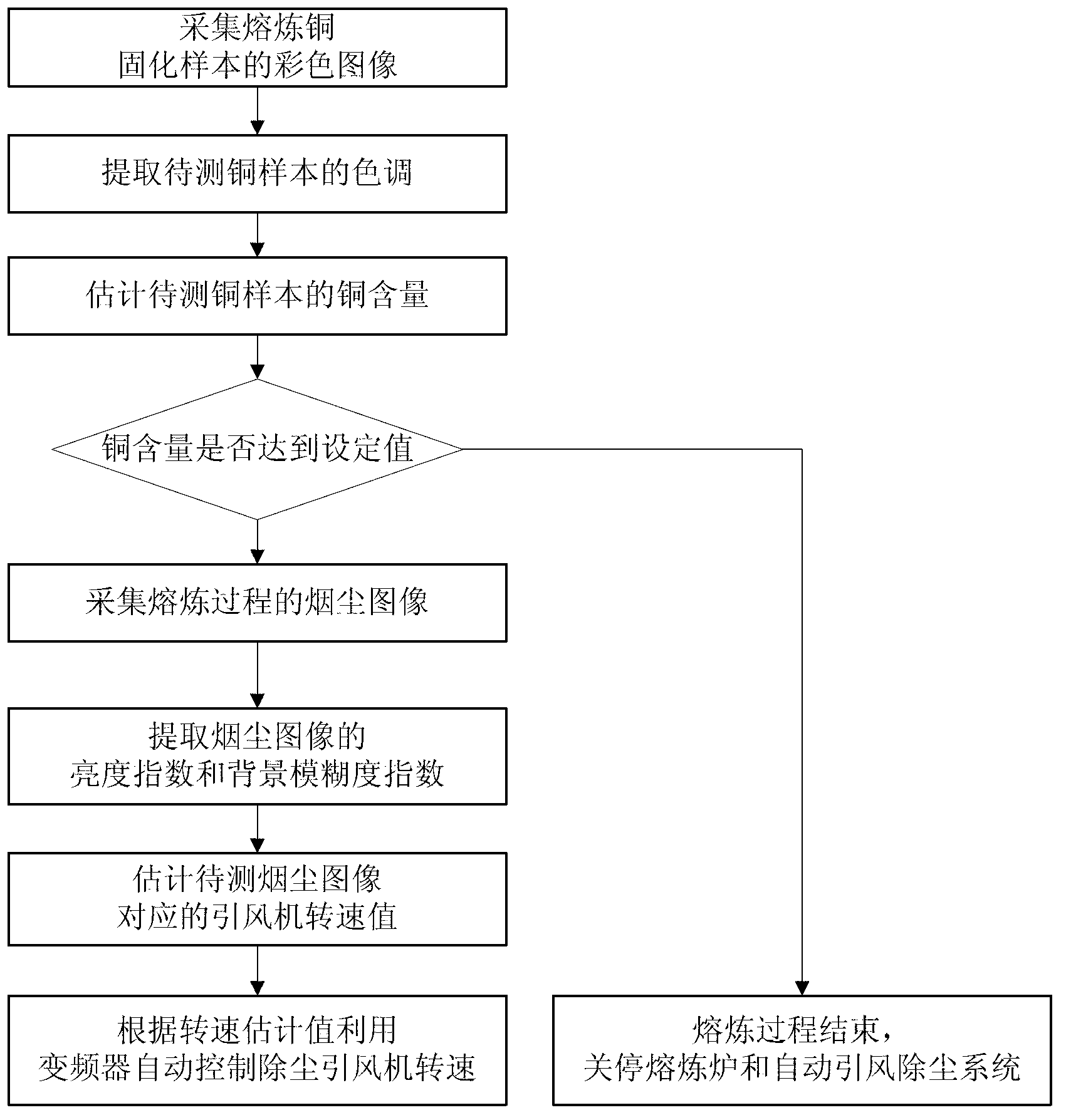

[0056] Such as figure 1 As shown, a control system of scrap copper smelting furnace based on image analysis includes: an industrial camera, a 3CCD color industrial camera, an industrial control computer and a frequency converter; the specific control of the system Process such as figure 2 shown.

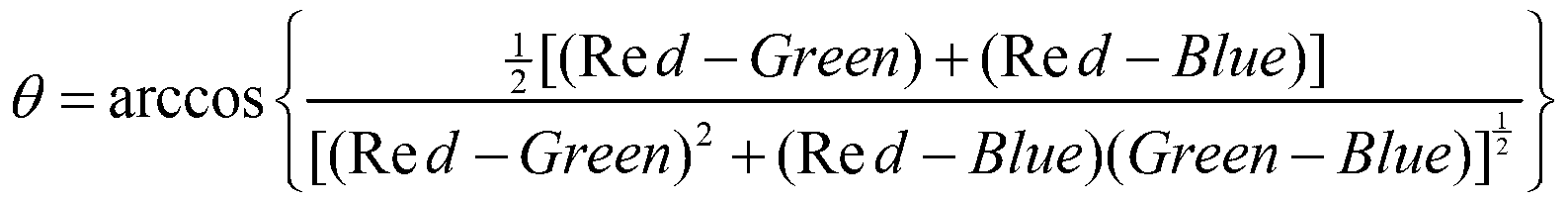

[0057] Firstly, during the smelting process, take n copper samples from the smelting furnace at a sampling interval of once every 15 minutes as n reference samples, use a 3CCD color industrial camera to collect the sample image of each reference sample, and send the image to the industry Control the computer; use the industrial camera to collect m-frame smoke and dust images in the smelting furnace at a sampling frequency of 7.5 frames per second as m-frame r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com