Cold-rolled dual-phase sheet steel with 400MPa-level tensile strength and preparation method thereof

A technology with a tensile strength of 450mpa, which is applied in the field of steel materials, can solve the problems of adverse effects on formability and welding performance, increased production costs, and unfavorable stamping forming, so as to avoid wrinkling on the surface of parts, improve hardenability, and stamping forming good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

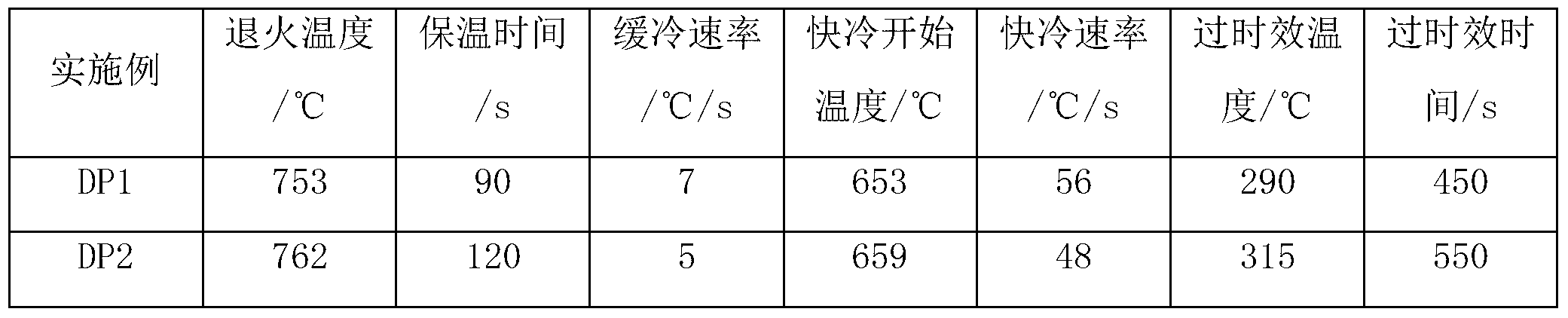

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

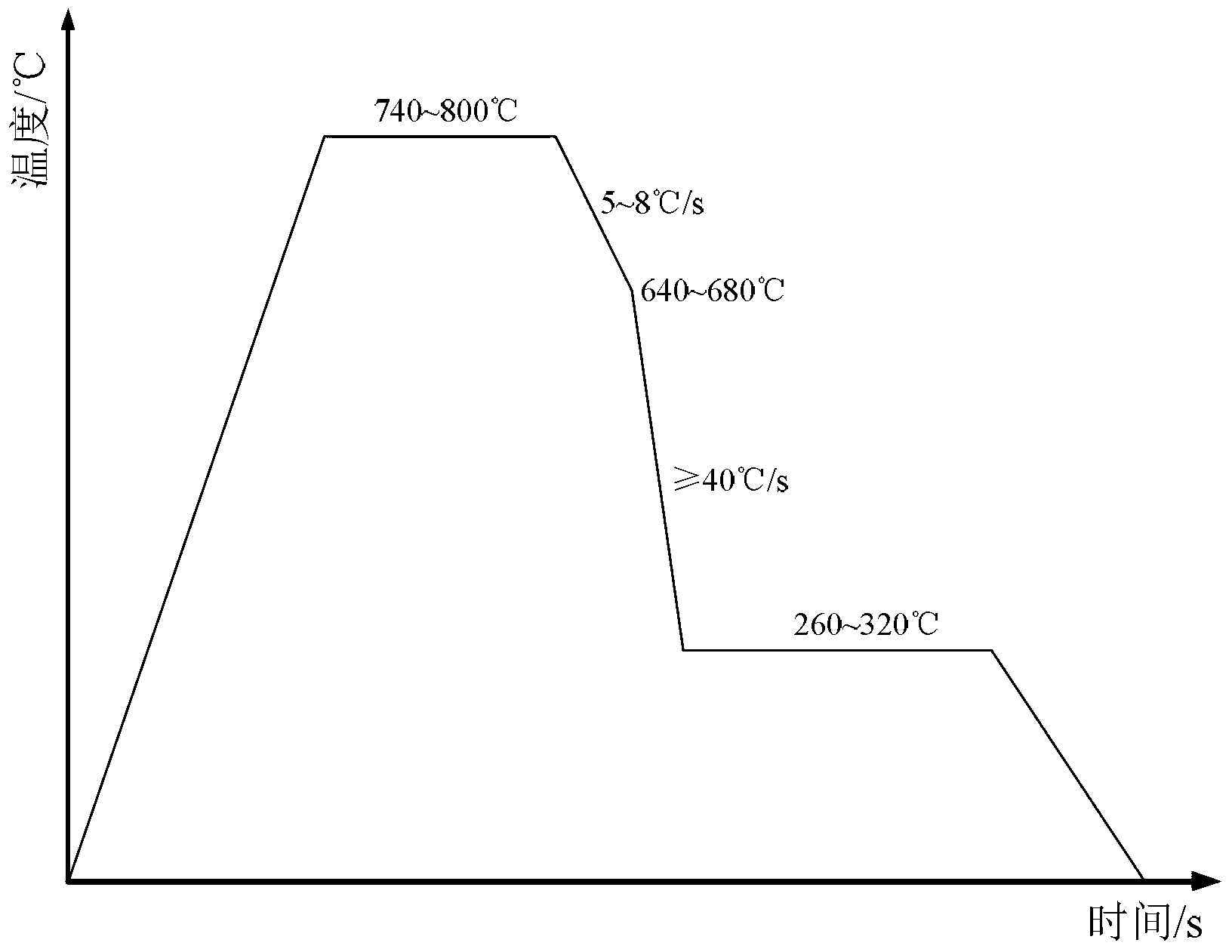

[0031] like figure 1 As shown, the annealing process of the present invention includes six stages of heating section, heat preservation section, slow cooling section, fast cooling section, overaging section and natural cooling section; in the heating section, the steel plate is rapidly heated to the two-phase region to obtain a certain amount of During the heat preservation process of the heat preservation section, the carbides are further dissolved, and the alloy elements are enriched in the austenite, which improves the stability of the austenite; in the slow cooling section, part of the austenite transforms into ferrite , the alloy elements are further enriched in the untransformed austenite; the austenite transforms into martensite in the rapid cooling section; the martensite is tempered at low temperature during the overaging process, and the internal stress obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com