Dust suppressant for constructional engineering and preparation method thereof

A technology of construction engineering and dust suppressant, which is applied in the field of atmospheric dust pollution control, can solve the problems of high cost of dust suppressant, low water retention capacity, and large corrosion of construction equipment, and achieve the goals of shortening curing time, saving cost, and reducing spraying volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

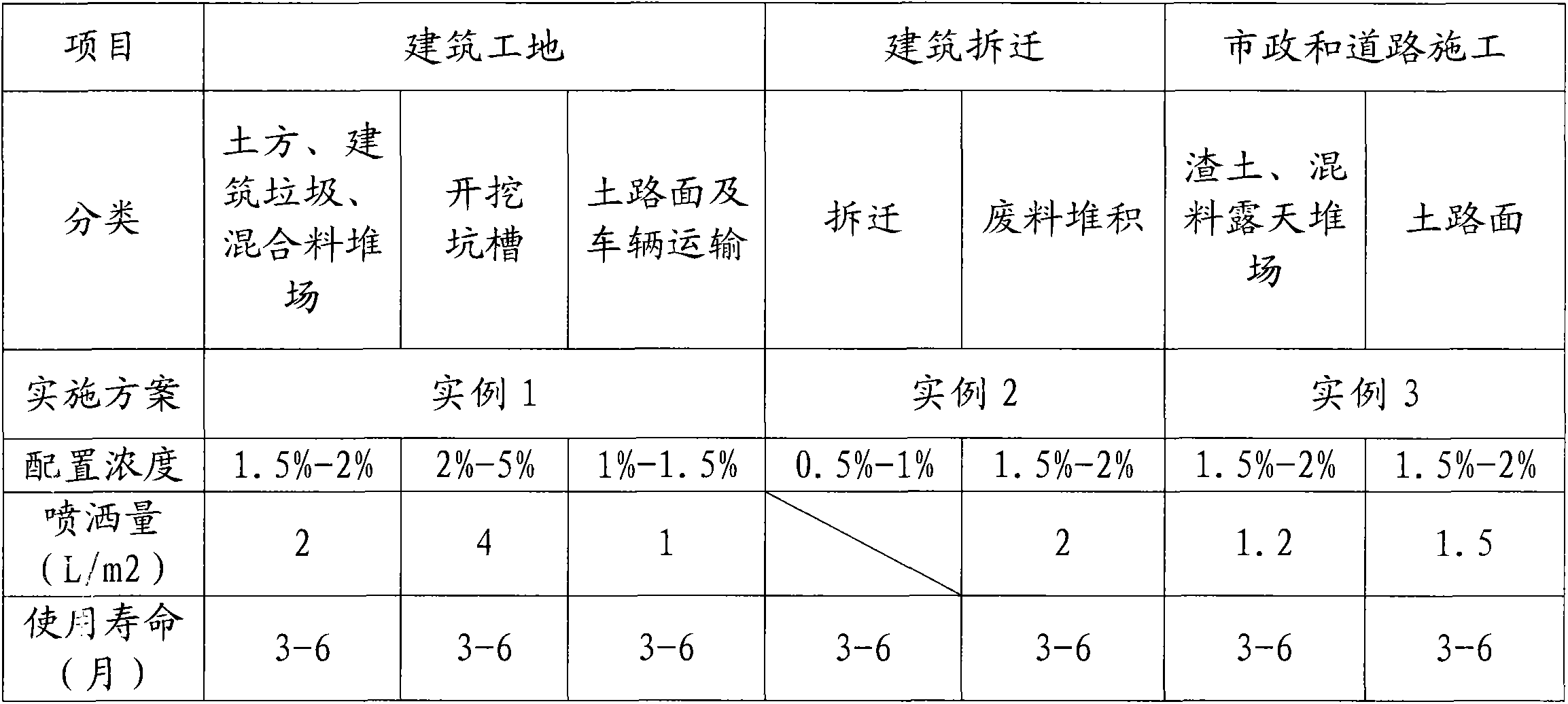

Embodiment 1

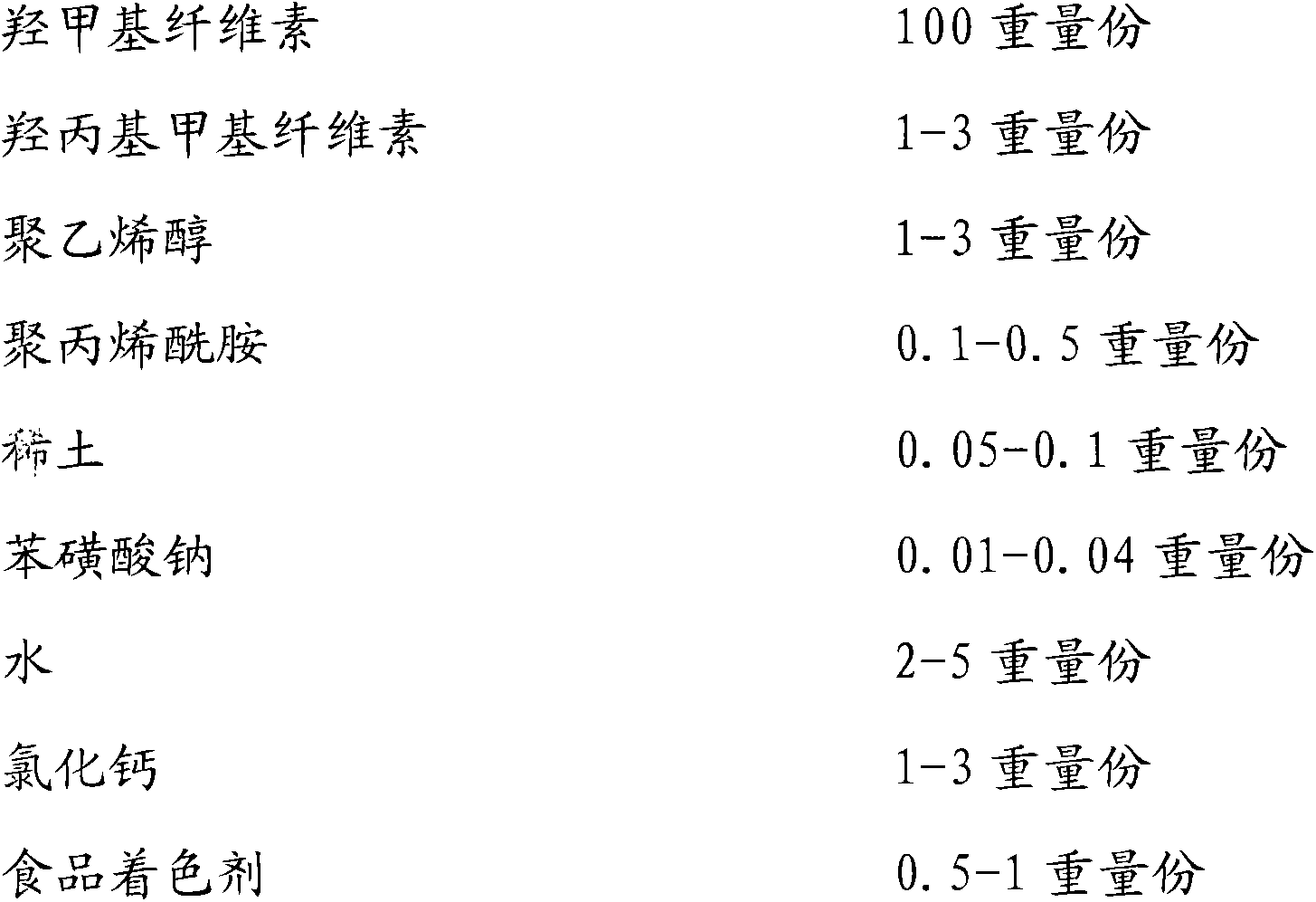

[0025] Embodiment 1: Preparation of construction dust suppressant composition of the present invention

[0026] 1) At normal temperature, 100 parts by weight of hydroxymethylcellulose, 1 part by weight of hydroxypropylmethylcellulose, and 2 parts by weight of polyvinyl alcohol are stirred at a high speed (stirring speed is 1500r / min) to achieve a uniform mixing state;

[0027] 2) Heat 2 parts by weight of water to 40°C, then add 0.1 parts by weight of polyacrylamide, 0.05 parts by weight of rare earth and 0.01 parts by weight of sodium benzenesulfonate in sequence, and stir and mix slowly (stirring speed is 150r / min) until the mixture is uniform;

[0028] 3) freezing the solution obtained in step 2) into a solid state at -10°C, and then sublimating the water in it into a gaseous state without going through a liquid state in a vacuum dryer with a pressure of 8 Pa to obtain a dry powder;

[0029] 4) Mix the mixture obtained in step 1) with the dry powder obtained in step 3), the...

Embodiment 2

[0030] Embodiment 2: Preparation of construction dust suppressant composition of the present invention

[0031] 1) At room temperature, 100 parts by weight of hydroxymethylcellulose, 3 parts by weight of hydroxypropylmethylcellulose, and 2 parts by weight of polyvinyl alcohol are stirred at a high speed (stirring speed is 1500r / min) to achieve a uniform mixing state;

[0032] 2) Heat 4 parts by weight of water to 50°C, then add 0.3 parts by weight of polyacrylamide, 0.07 parts by weight of rare earth and 0.02 parts by weight of sodium benzenesulfonate in sequence, and stir and mix slowly (stirring speed is 150r / min) until the mixture is uniform;

[0033] 3) freezing the solution obtained in step 2) into a solid state at -10°C, and then sublimating the water in it into a gaseous state without going through a liquid state in a vacuum dryer with a pressure of 8 Pa to obtain a dry powder;

[0034] 4) Mix the mixture obtained in step 1) with the dry powder obtained in step 3), then...

Embodiment 3

[0035] Embodiment 3: Preparation of construction dust suppressant composition of the present invention

[0036] 1) At normal temperature, 100 parts by weight of hydroxymethylcellulose, 3 parts by weight of hydroxypropylmethylcellulose, and 3 parts by weight of polyvinyl alcohol are stirred at a high speed (stirring speed is 1500r / min) to achieve a uniform mixing state;

[0037] 2) Heat 5 parts by weight of water to 60°C, then add 0.5 parts by weight of polyacrylamide, 0.1 parts by weight of rare earth and 0.04 parts by weight of sodium benzenesulfonate in sequence, and stir and mix slowly (stirring speed is 150r / min) until the mixture is uniform;

[0038] 3) freezing the solution obtained in step 2) into a solid state at -10°C, and then sublimating the water in it into a gaseous state without going through a liquid state in a vacuum dryer with a pressure of 8 Pa to obtain a dry powder;

[0039] 4) Mix the mixture obtained in step 1) with the dry powder obtained in step 3), the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com