Preparation method of crimson reactive dye

A reactive dye and deep red technology, applied in reactive dyes, dyeing methods, organic dyes, etc., can solve the problems of low product content, high energy consumption, environmental pollution, etc., and achieve high color fixation rate, low energy consumption, and low raw material consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

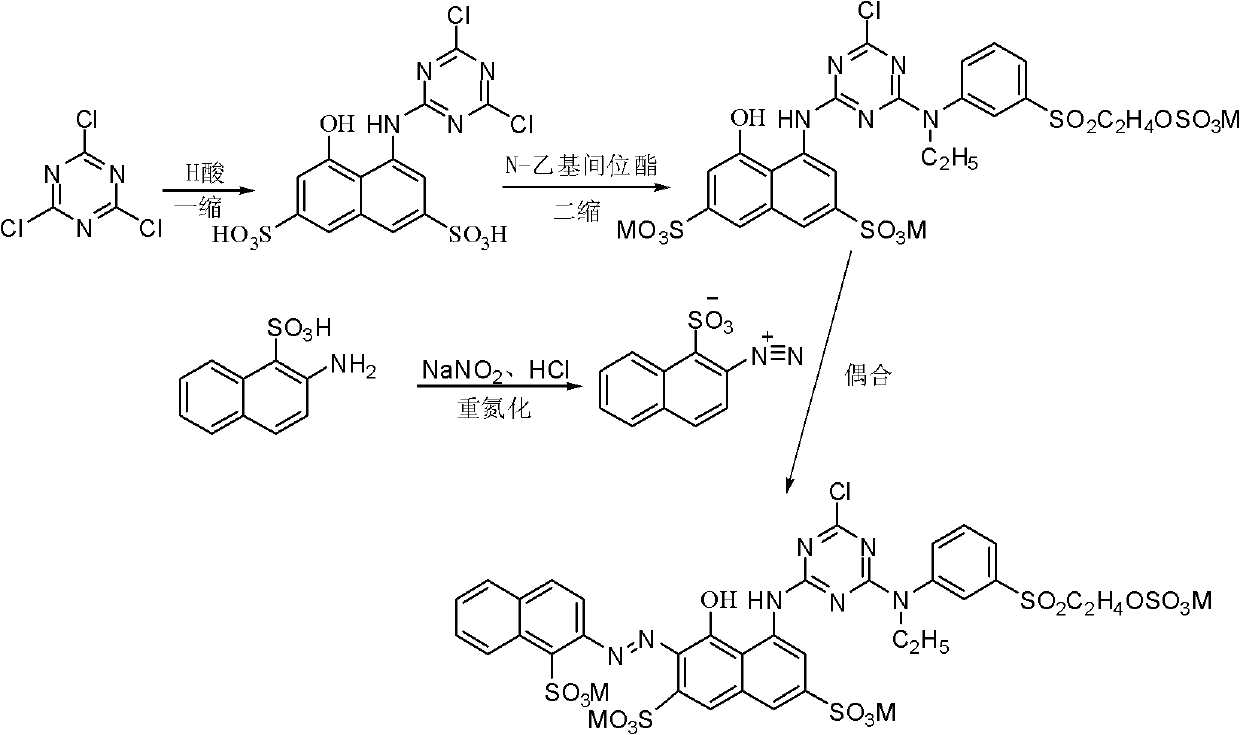

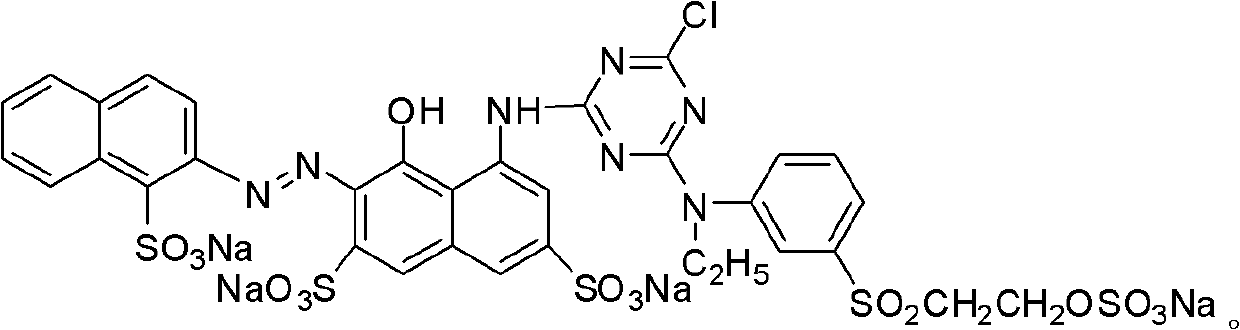

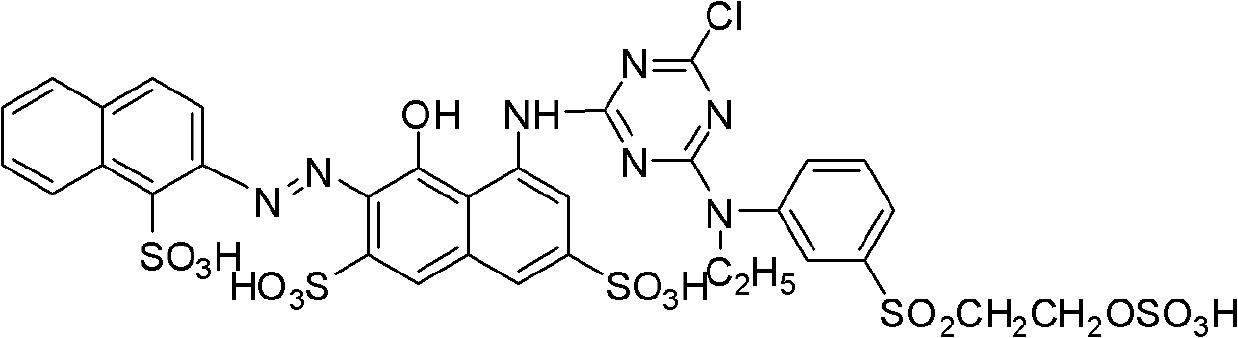

Method used

Image

Examples

Embodiment 1

[0026] a) One condensation

[0027] Weigh 1.88 parts of cyanuric chloride, add 18 parts of water and crushed ice, and beat at 0-5°C for 45 minutes. At the same time, weigh 3.41 parts of H acid in 15 parts of water, adjust the pH to 6-6.5 with sodium carbonate, and dissolve it completely. After the beating is finished, drop the above-mentioned H acid solution into the cyanuric chloride suspension within 1 hour. After the dropwise addition, adjust the pH value of the reaction to 2.0-2.5 with sodium carbonate, and react for 2 hours until there is no free H acid, which is the end point.

[0028]

[0029] b) Secondary condensation

[0030] Weigh 3.03 parts of N-ethyl meta-ester and add it to the above-mentioned primary condensation reaction solution, and at the same time raise the temperature to 30-34°C, adjust the pH value to 3-3.5 with sodium carbonate, keep this temperature and pH value for about 4 hours, and perform HPLC The detection of the disappearance of the N-ethyl m...

Embodiment 2

[0039] Repeat the material ratio and process conditions in the operation process of each step in Example 1, the difference is in the secondary condensation of step (b) in Example 1, the reaction temperature is 26~30 ° C, and the pH value is 4~4.5; ( c) After diazotization, adjust the pH of the diazonium salt to 6.5 to 7; (d) during the coupling, adjust the temperature of the dicondensate solution to 15°C, pH = 7 to 7.5, and the pH of the coupling reaction to 8 to 8.5, and finally obtain 15 Part reactive dye crimson.

Embodiment 3

[0041]Repeat the material ratio and process conditions in the operation process of each step in Example 1, the difference is in the secondary condensation of step (b) in Example 1, the reaction pH value is 4~4.5; (c) in the diazotization, Adjust the pH of the diazonium salt at 10-15°C to 6.5-7; (d) in coupling, adjust the temperature of the dicondensate solution to 20°C, pH=7-7.5, and finally obtain 15 parts of reactive dye deep red.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com