High-speed precision pneumatic micro main shaft

A kind of pneumatic micro and precise technology, applied in clamping, supporting, positioning device and other directions, can solve the problems of high cost and difficult to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

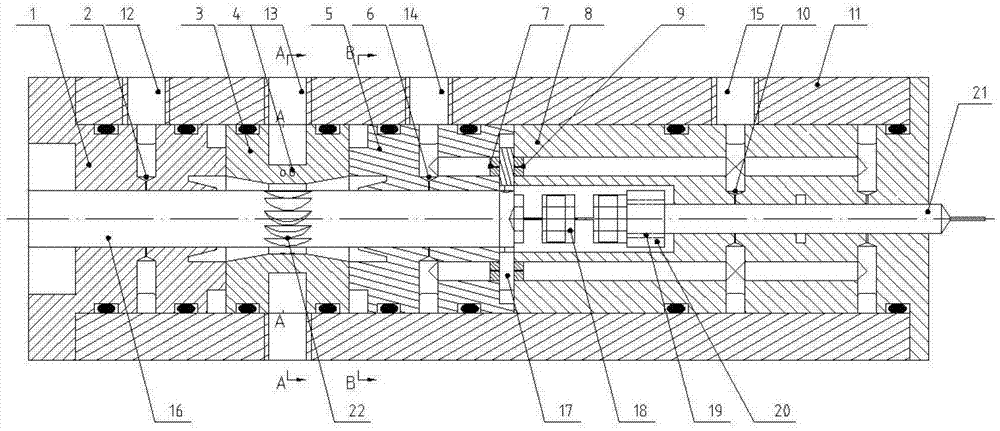

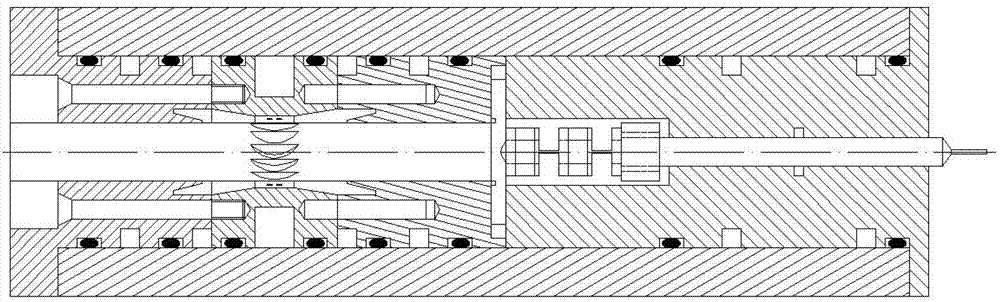

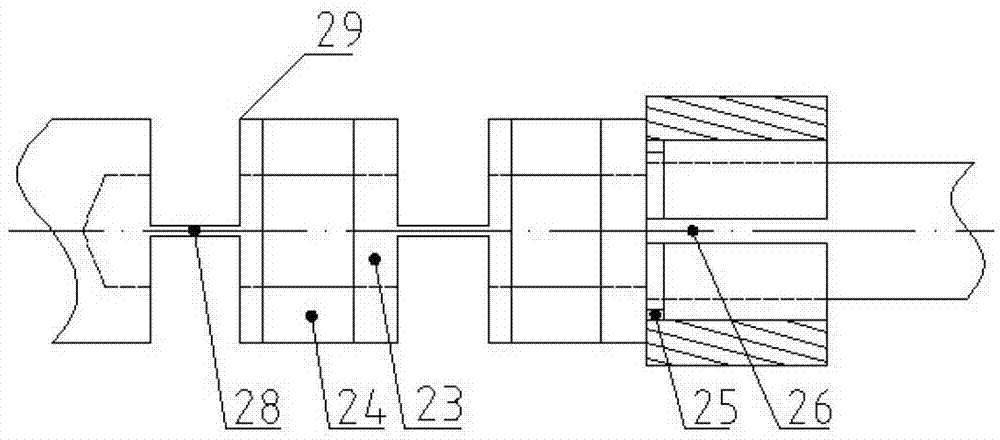

[0032] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0033] See attached figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the turbine shaft 16 is installed in the casing 11 using the rear end bearing 1 and the intermediate bearing 5, the turbine shaft 16 is integrated with the turbine 22 and the outer diameter of the turbine 22 is not greater than the outer diameter of the turbine shaft 16, and the casing 11 is provided with Corresponding to the turbine 22, the jet-driven double-row nozzle 3 is provided with two circles of small holes 4, and the exhaust port 27 is arranged at both ends of the turbine chamber of the turbine 22. The actuator adopts the front end bearing 8 to be installed in the box body 11 The turbine shaft 16 is provided with a baffle 17 installed between the intermediate bearing 5 and the front end bearing 8, the rear end bearing 1 is provided with a first aerostatic radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com