Pectinate gas mixing unit and pectinate gas mixer

A gas mixing and comb-like technology, which is applied in the directions of gas and gas/vapor mixing, fluid mixer, mixer, etc., can solve the problems of high manufacturing cost, long mixed gas path, poor chemical stability, etc. Facilitate large-scale management and reduce the effect of chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

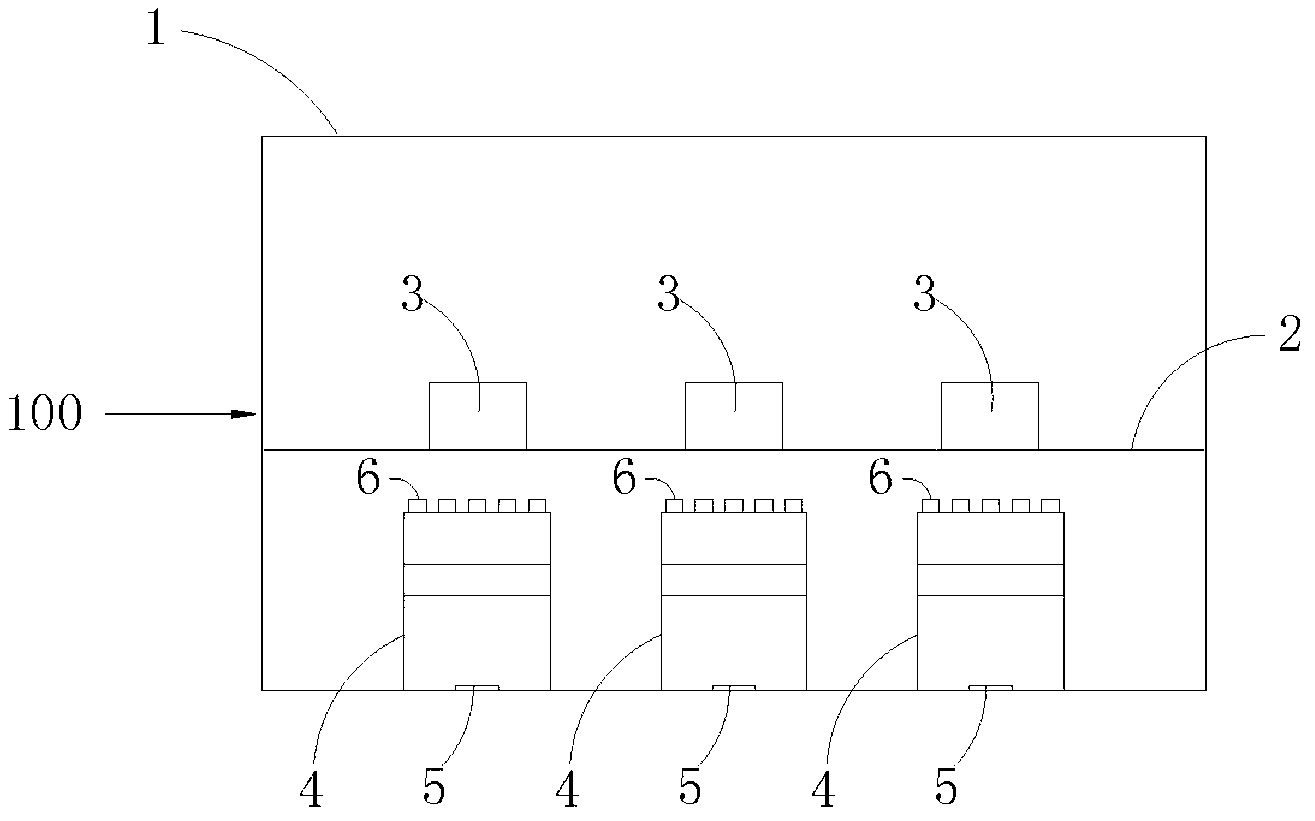

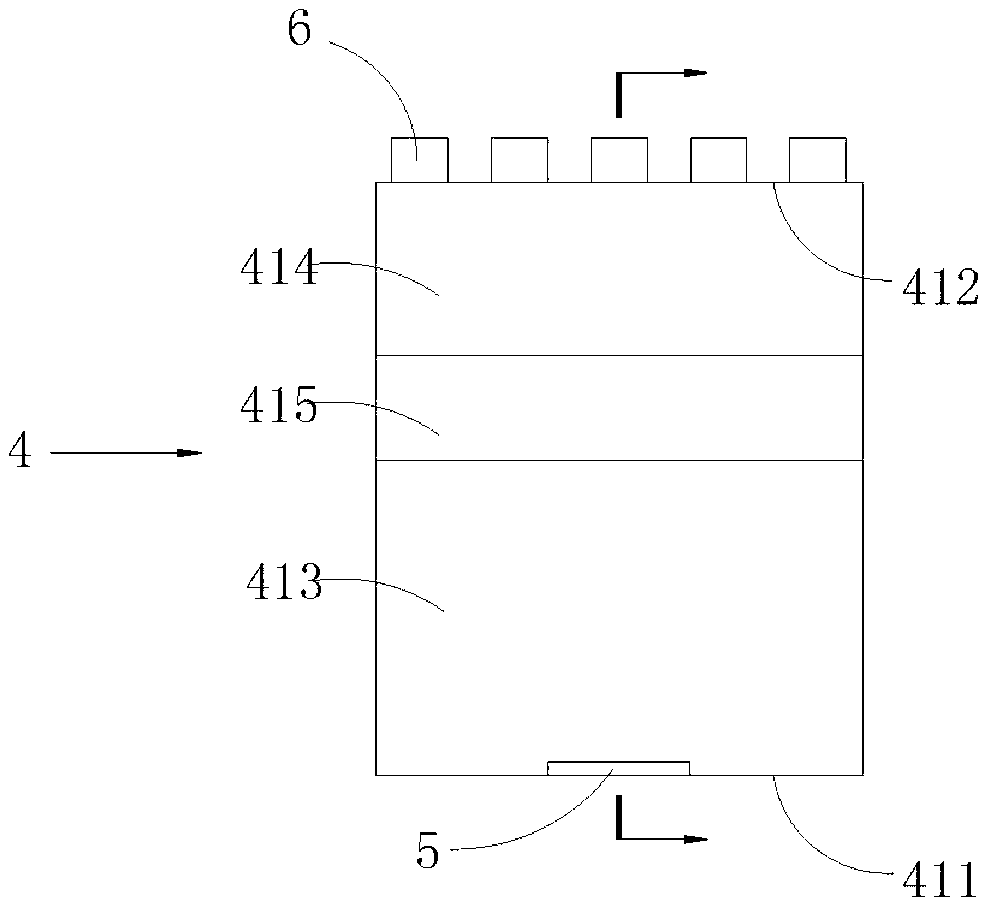

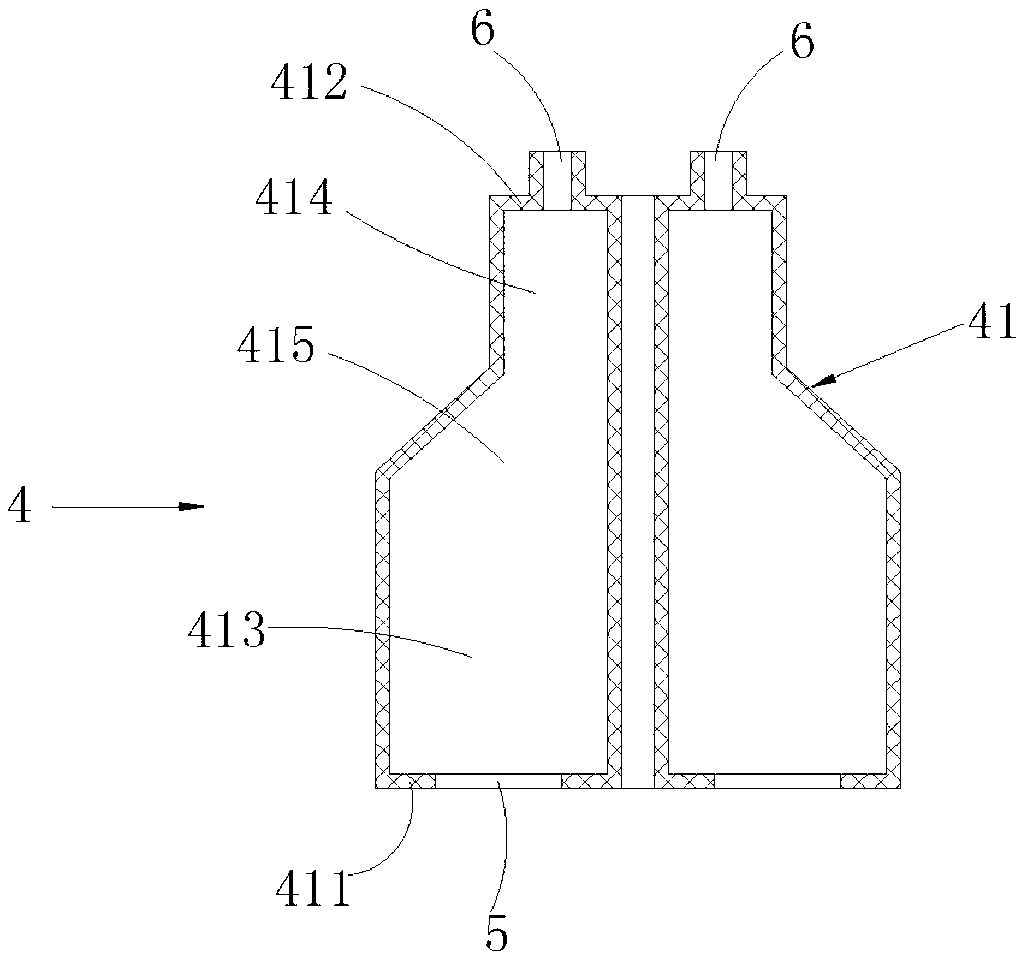

[0018] This embodiment is a preferred embodiment of the comb gas mixing unit provided by the present invention, please refer to Figure 1-3 .

[0019] The comb-shaped gas mixing unit 100 includes a sealed box 1, and a carrier plate 2 is arranged inside the sealed box 1; a plurality of coating areas 3 are arranged on one side of the carrier plate 2, and the other side corresponds to each of the coating areas 3. There are several air injection assemblies 4; the air injection assembly 4 includes at least two air intake chambers 41, any of the air intake chambers 41 is provided with an air inlet 5 on the first box wall 411 away from the carrier plate 1 1. A number of air injection ports 6 are opened on the second box wall 412 close to the loading plate 3 , and the air injection openings 6 are arranged at a distance from the loading plate 2 .

[0020] The comb-shaped gas mixing unit provided by the present invention is provided with a plurality of coating areas 3, and each coating...

Embodiment 2

[0023] This embodiment is a preferred embodiment of the comb-shaped gas mixer provided by the present invention. The comb-shaped gas mixing unit 100 used in this embodiment is based on the comb-shaped gas mixing unit 100 described in Embodiment 1. Please refer to Figure 4 . details as follows:

[0024] The comb-shaped gas mixer includes the comb-shaped gas mixing unit 100 as described in the embodiment and the intake main pipe 7 equal to the number of the air inlets 5 on the same comb-shaped gas mixing unit 100, each of which The air inlets 5 at the same position on the comb gas mixing unit 100 are connected to the same air inlet main pipe 7 through an air inlet branch pipe 8 . The comb-shaped gas mixer provided by the present invention is convenient to realize large-scale management by arranging the comb-shaped gas mixing units provided by the present invention in parallel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com