Full-automatic high-energy laser surface hardening system

A high-energy laser, fully automatic technology, applied in the field of high-energy laser surface hardening, can solve the problems of precision machining of difficult and complex geometric surfaces, large depth of quenching heat treatment, uneven quenching layer, etc. Effects of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

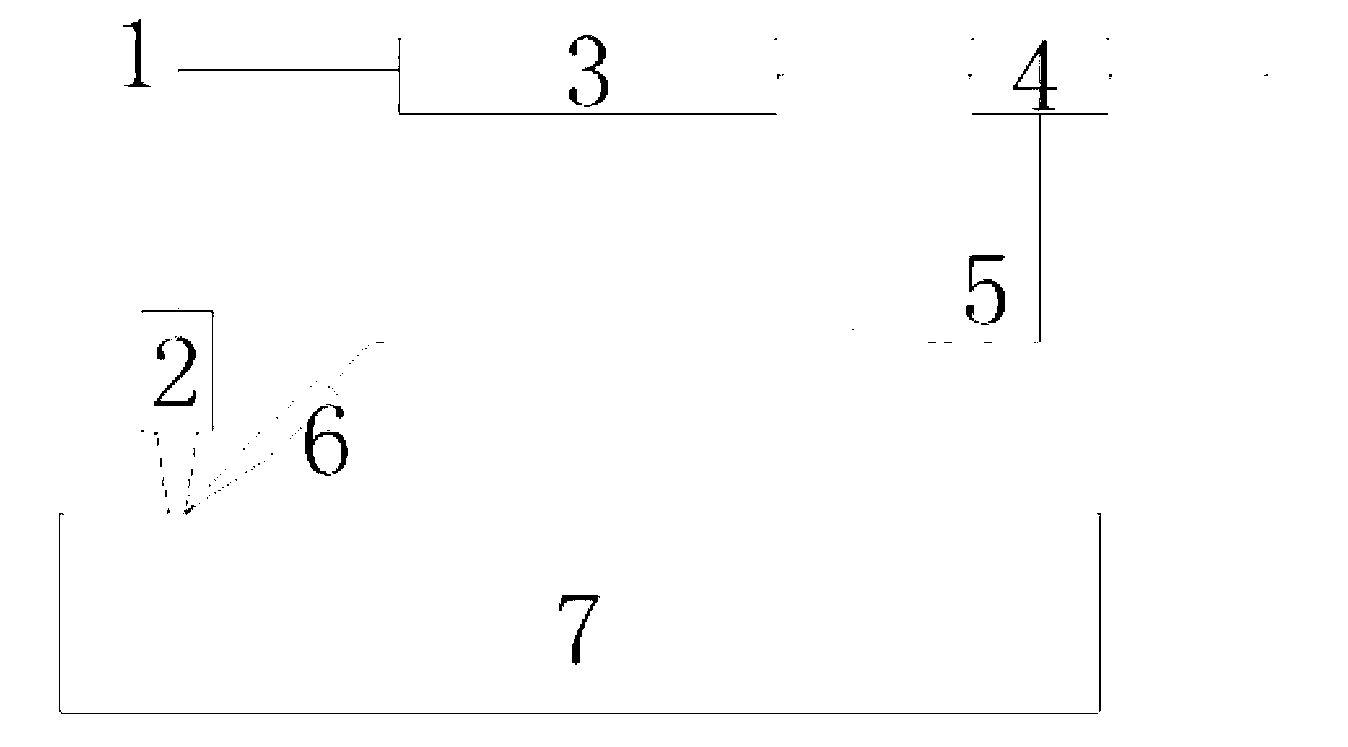

[0028] A fully automatic high-energy laser surface hardening system, through the surface temperature closed-loop control system (such as figure 1 ), high-energy laser, feedback system, real-time surface temperature detection system, and laser power automatic adjustment system. Control the metal surface temperature within a certain range, so that it is in the austenitic state.

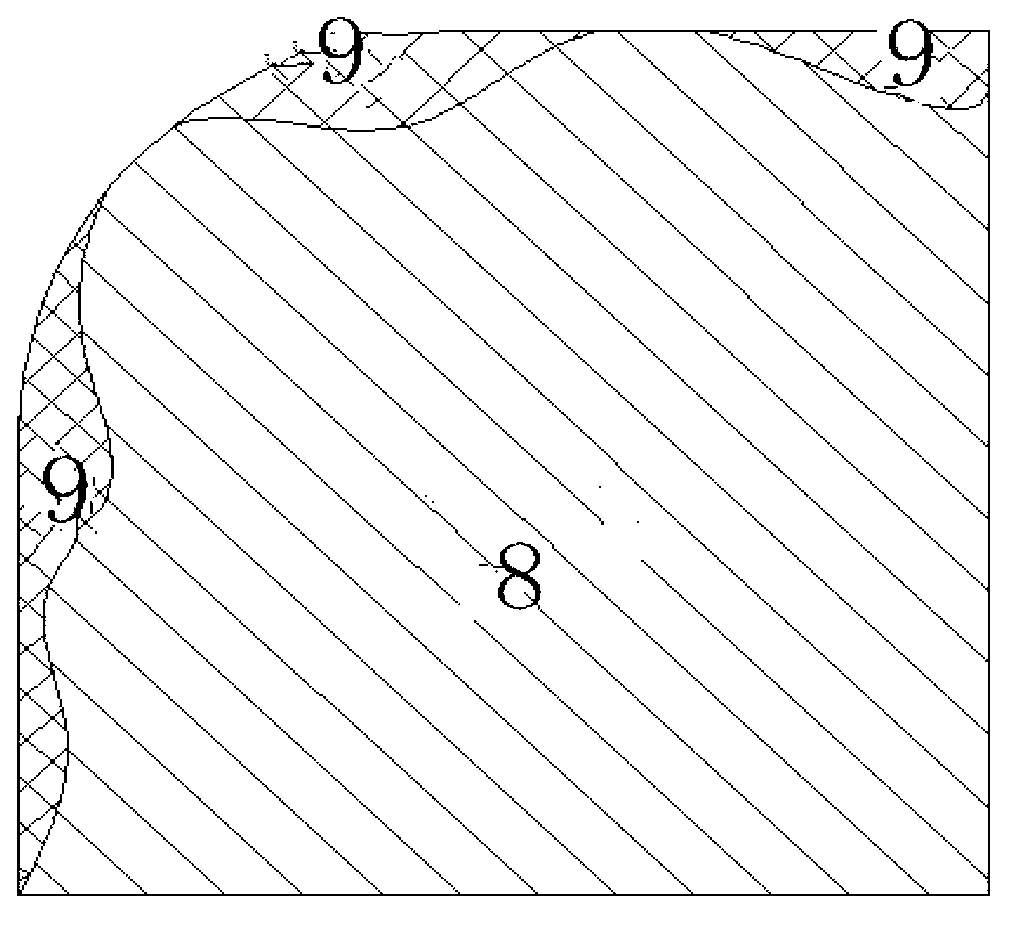

[0029] The high-energy laser generated by the fiber laser is irradiated on the surface of the workpiece, and a spot with a diameter of 4-6mm is formed on the surface of the workpiece. When the corner of the workpiece is hardened, due to the concentration of energy, the tip effect occurs, and the temperature curve rises sharply, resulting in a large depth of hardened layer at the corner. In other parts, and cause large thermal deformation.

[0030] The high temperature sensor is used to detect the metal surface temperature in real time, and the spectral signal is reflected by light wave reflection. Afte...

Embodiment 2

[0037] The traditional quenching process hardens the corner of the workpiece:

[0038] Heat the corner workpiece to be processed above the austenite temperature and below the melting point, and keep it for a certain period of time.

[0039] Quickly immerse the workpiece in the quenching medium and cool it quickly, so that a layer of martensitic structure is formed on the surface

[0040] Reheat and temper the quenched workpiece to eliminate defects such as thermal cracks

[0041] Post-processing of workpieces

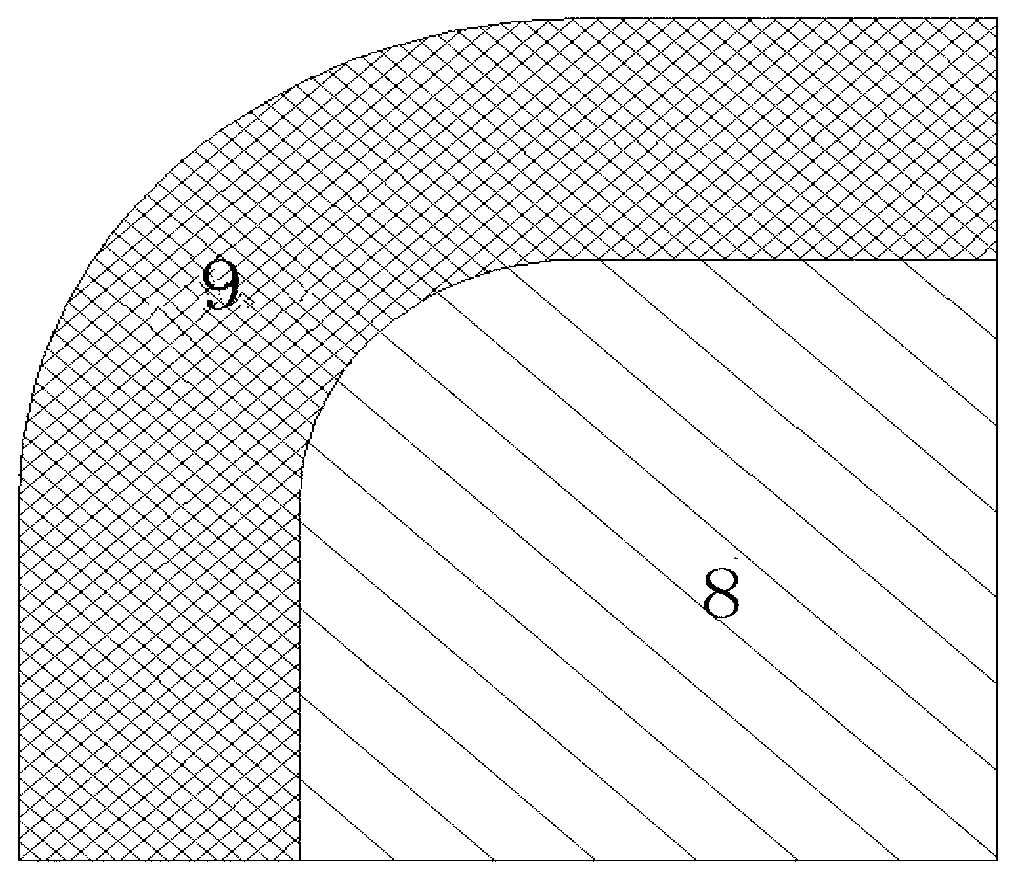

[0042] Carry out metallographic analysis on the corner part to observe whether the depth of the hardened layer is uniform (such as image 3 ). Comparison of fully automatic high-energy laser surface hardening and quenching:

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com