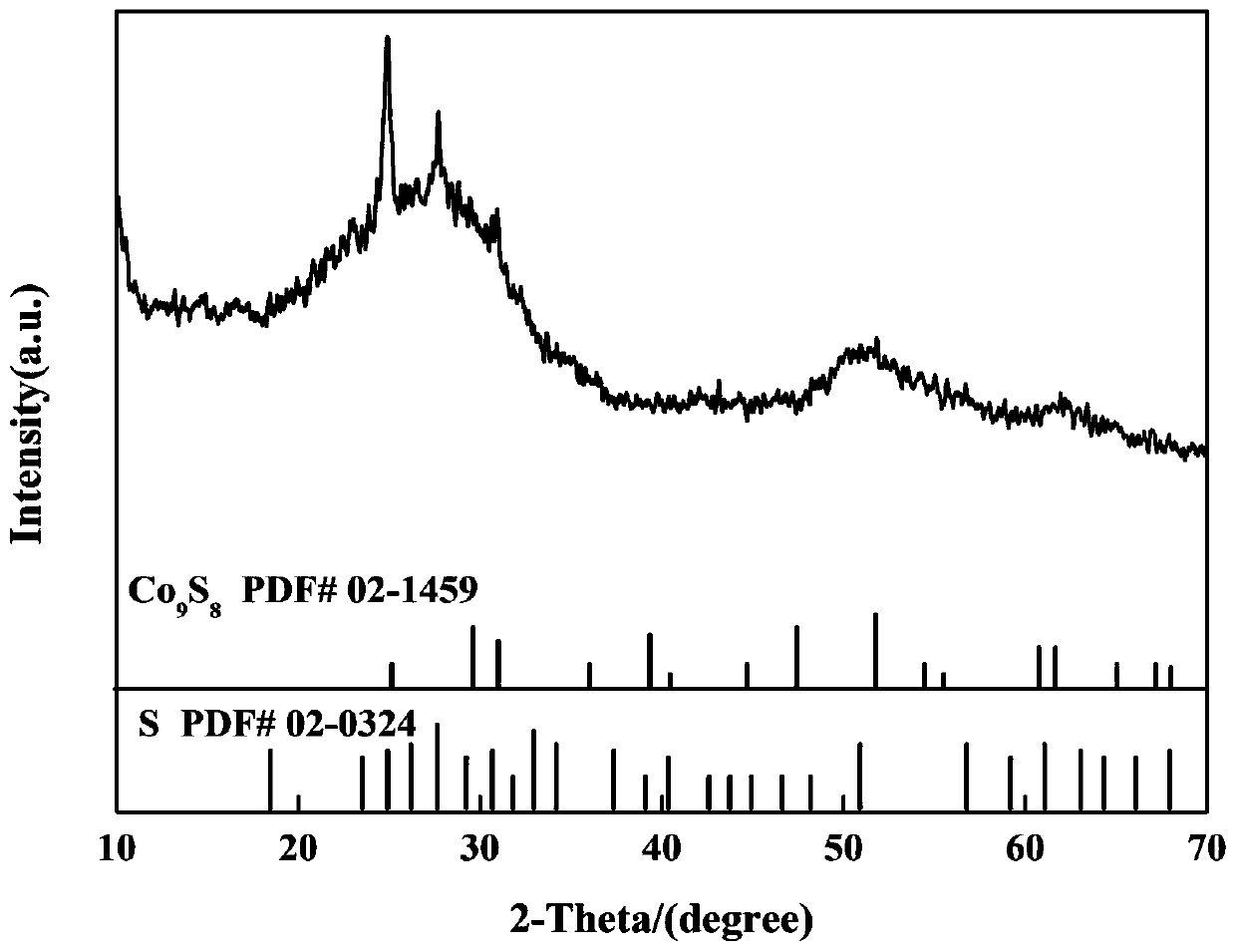

Preparation method of sheet-like cobalt sulfide composite flexible carbon cloth electrode material

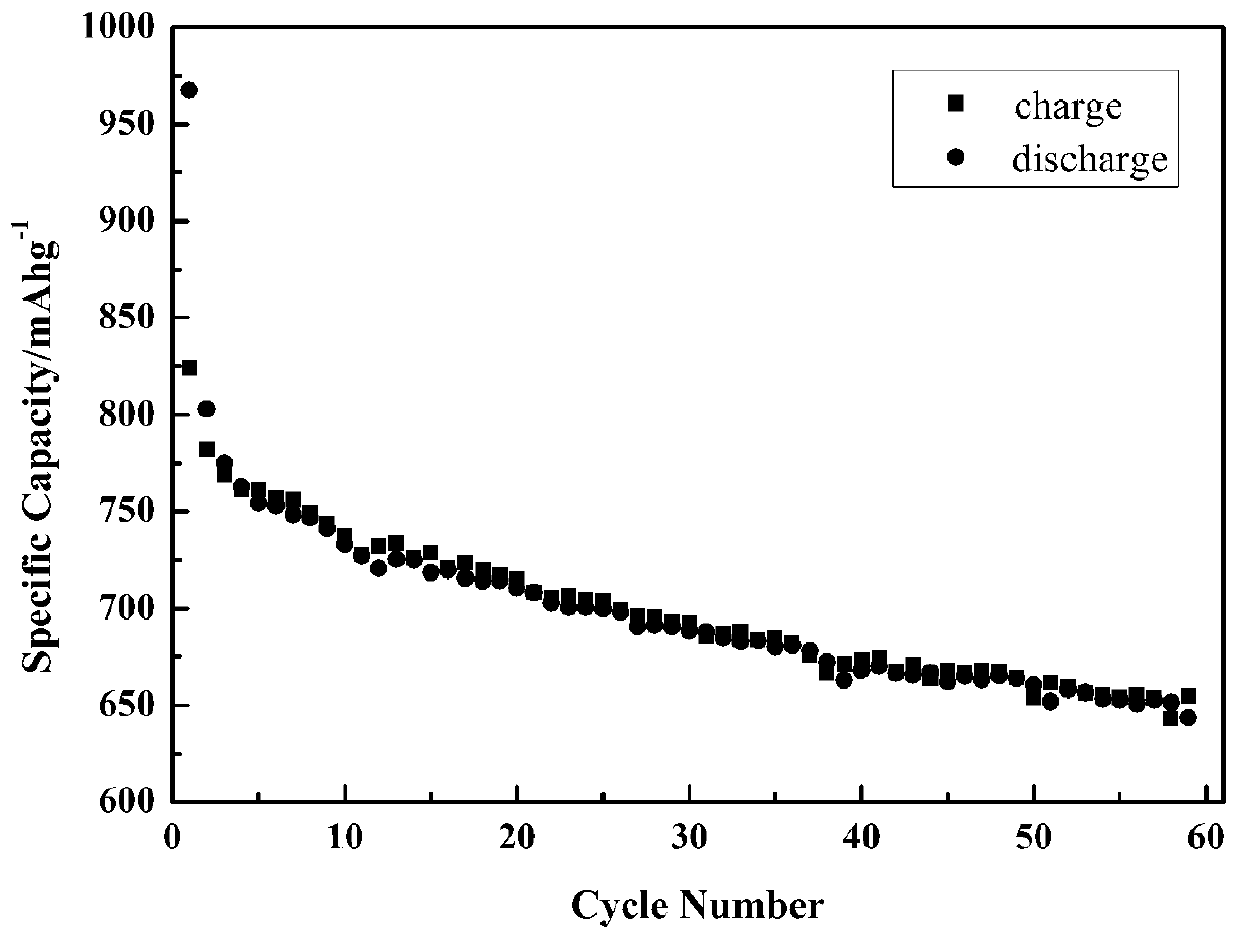

A carbon cloth electrode, cobalt sulfide technology, applied in the field of electrochemistry, can solve the problems of poor rate performance, poor cycle performance, electrode pulverization, etc., and achieve the effects of excellent performance, low cost, and improved bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Mix isopropanol and glycerol at a volume ratio of 1:2 to obtain a mixed solution, take 1g of analytically pure cobalt nitrate hexahydrate and add it to 30ml of mixed solution to obtain solution A, take 0.6g of analytically pure sulfur Add acetamide to 10ml deionized water to obtain solution B;

[0032] 2) Mix solution A and solution B, and magnetically stir at a speed of 600r / min for 1h to form precursor solution C;

[0033] 3) Add 3 mg of CBTA to solution C, and then ultrasonically disperse for 1 hour to obtain solution D;

[0034] 4) Take 3*4cm square carbon cloth as anode, graphite plate as cathode, 40g / L ammonium dihydrogen phosphate aqueous solution as electrolyte, oxidize at 5V for 2min, and then alternately wash with ultrapure water and ethanol for 3 After drying in the oven;

[0035] 5) Soak the pretreated carbon cloth completely into the solution D, put the solution D and the carbon cloth into the hydrothermal reaction kettle according to the filling ratio...

Embodiment 2

[0041] 1) Mix isopropanol and glycerol at a volume ratio of 1:2 to obtain a mixed solution, take 1.3g of analytically pure cobalt nitrate hexahydrate and add it to 35ml of mixed solution to obtain solution A, take 0.8g of analytically pure cobalt nitrate hexahydrate Thioacetamide was added to 15ml deionized water to obtain solution B;

[0042] 2) Mix solution A and solution B, and magnetically stir at a speed of 650r / min for 2h to form precursor solution C;

[0043] 3) Add 4.5 mg of CBTA to solution C, and then ultrasonically disperse for 2 hours to obtain solution D;

[0044] 4) Take a 3*4cm square carbon cloth as the anode, a graphite plate as the cathode, and a 45g / L ammonium dihydrogen phosphate aqueous solution as the electrolyte, oxidize it at 5V for 2min, and then wash it alternately with ultrapure water and ethanol for 5 After drying in the oven;

[0045] 5) Soak the pretreated carbon cloth completely into the solution D, put the solution D and the carbon cloth into ...

Embodiment 3

[0048] 1) Mix isopropanol and glycerol at a volume ratio of 1:2 to obtain a mixed solution, take 1.5g of analytically pure cobalt nitrate hexahydrate and add it to 40ml of mixed solution to obtain solution A, take 1g of analytically pure sulfur Add acetamide to 20ml deionized water to obtain solution B;

[0049] 2) Mix solution A and solution B, and magnetically stir at a speed of 700r / min for 2.5h to form precursor solution C;

[0050] 3) Add 6 mg of CBTA to solution C, and then ultrasonically disperse for 3 hours to obtain solution D;

[0051] 4) Take a 3*4cm square carbon cloth as the anode, a graphite plate as the cathode, and a 50g / L ammonium dihydrogen phosphate aqueous solution as the electrolyte, oxidize it at 5V for 2min, and then alternately wash it with ultrapure water and ethanol for 6 After drying in the oven;

[0052] 5) Soak the pretreated carbon cloth completely into the solution D, put the solution D and the carbon cloth into the hydrothermal reaction kettle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com