Polyurethane-base piezoelectric conductive intelligent composite damping material and preparation method thereof

A composite damping material and polyurethane technology, applied in the field of damping materials, to achieve the effects of widening the damping temperature range, low price, and improving the loss factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of composite damping material of the present invention comprises the following steps:

[0034] 1) Preparation of polyurethane matrix: heat polyether diol in vacuum to remove moisture and air bubbles, then add diisocyanate, stir evenly, slowly heat up to reaction temperature 80±5°C, react for 2-3 hours, after the reaction is completed, place it at room temperature to form the polyurethane matrix , and the molar ratio of polyether diol to diisocyanate is 1:2.9; wherein, the polyether diol is TDB, and the diisocyanate is toluene diisocyanate (TDI). The purpose of vacuum heating polyether diol to remove moisture and air bubbles is to prevent the reaction of water and isocyanate to generate CO 2 Seriously affect the performance of the material. TDB was evacuated at 105°C for 2 hours and then cooled to 60°C, then TDI was metered and preheated, and reacted at 80°C for 2-3 hours.

[0035] 2) Treatment of piezoelectric ceramic lead zirconate titanate: us...

Embodiment 1

[0048] 1) Synthesis of polyurethane matrix: Add polyether diol TDB466.2g into a three-necked flask equipped with a vacuum device, keep vacuuming at 105°C for 2 hours to remove moisture in polyether glycol, stop vacuuming and cool down to 60°C Nearby, 117.7g of toluene diisocyanate TDI was added to the experimental device, the molar ratio of it to TDB was 2.9:1, and the temperature was gradually raised to 80°C for 2-3 hours to achieve a light yellow transparent viscous liquid.

[0049] 2) Treatment of piezoelectric ceramic lead zirconate titanate: use ethanol as a solvent to prepare a solution of 1-3wt% KH-550, take an equal amount of the solution and ceramic powder for stirring treatment, and stir at 60°C for 2- 4h, make it fully mixed, and after the solution is clarified, dry the separated ceramic powder at 110°C for 2h to obtain a surface-modified piezoelectric ceramic powder, and store it in a dry place for later use.

[0050] 3) Preparation of piezoelectric-conductive poly...

Embodiment 2

[0057] 1) Repeat step 1) in Example 1.

[0058] 2) Repeat step 2) in Example 1.

[0059] 3) Preparation of piezoelectric-conductive polyurethane composite damping material: Accurately weigh 20g of polyurethane matrix, 12g of piezoelectric ceramics, and 0.6g of conductive polyaniline particles at one time, ultrasonically disperse at 60°C for 0.5h, and then remove air bubbles and moisture in a vacuum drying oven. Then add 1.29 g of molten trimethylolpropane, stir slowly and evenly, and solidify at 100° C. to obtain a polyurethane composite damping material after degassing.

[0060] 4) Repeat step 4) in Example 1.

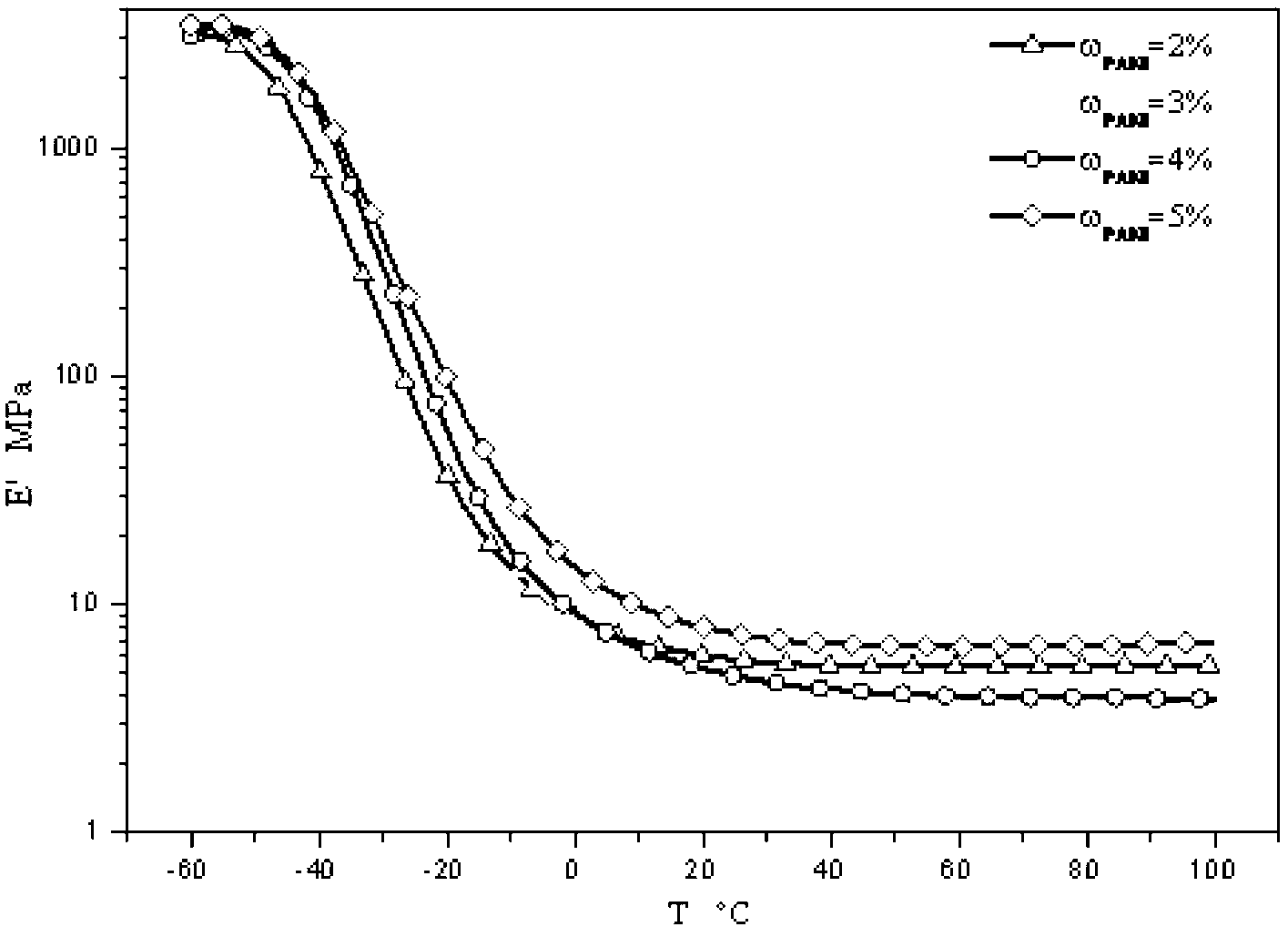

[0061] figure 1 Medium ω PANI =3% is the storage modulus versus temperature curve of the prepared damping material before polarization.

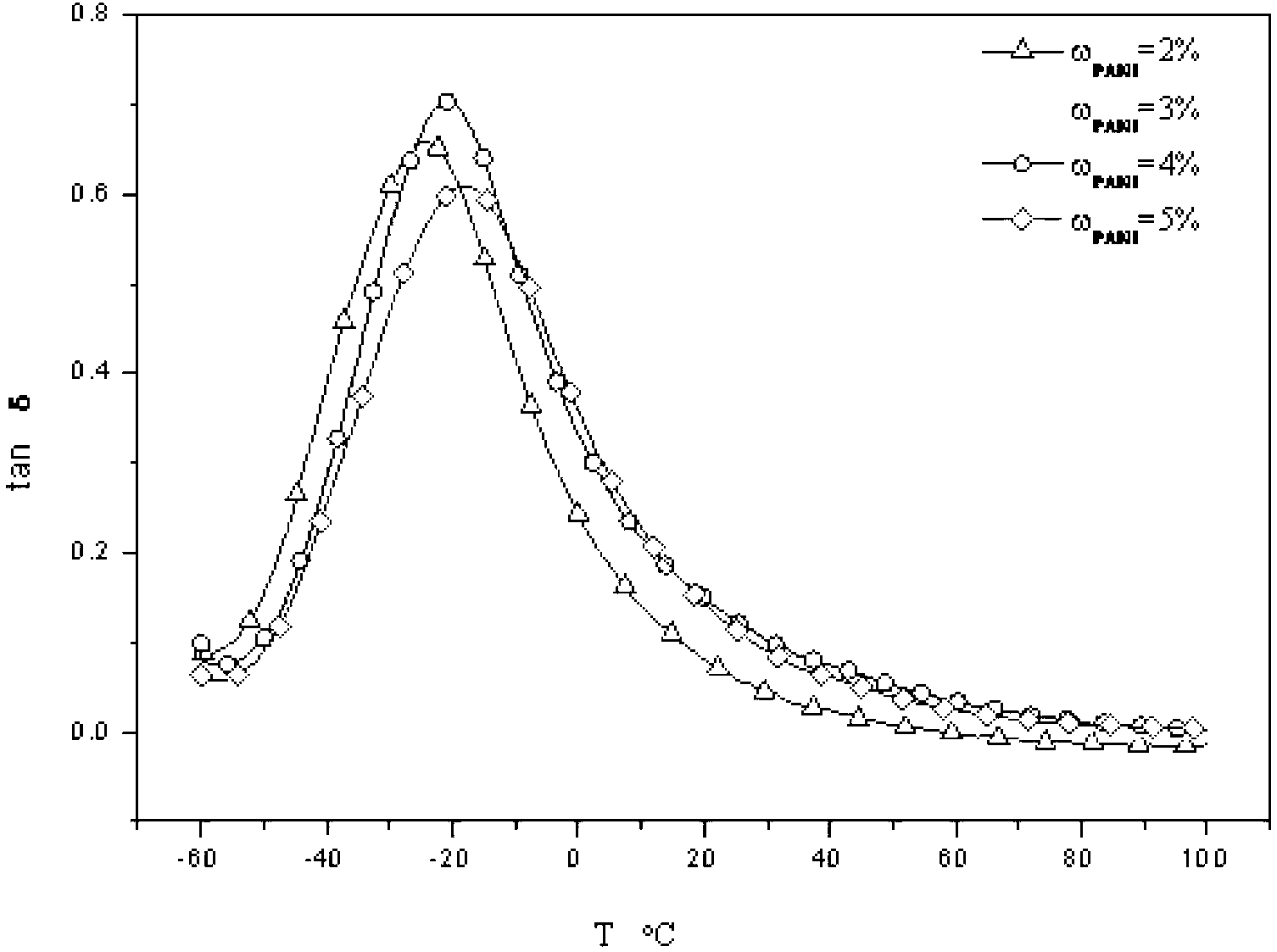

[0062] figure 2 Medium ω PANI =3% is the curve of the loss factor versus temperature before polarization of the prepared damping material.

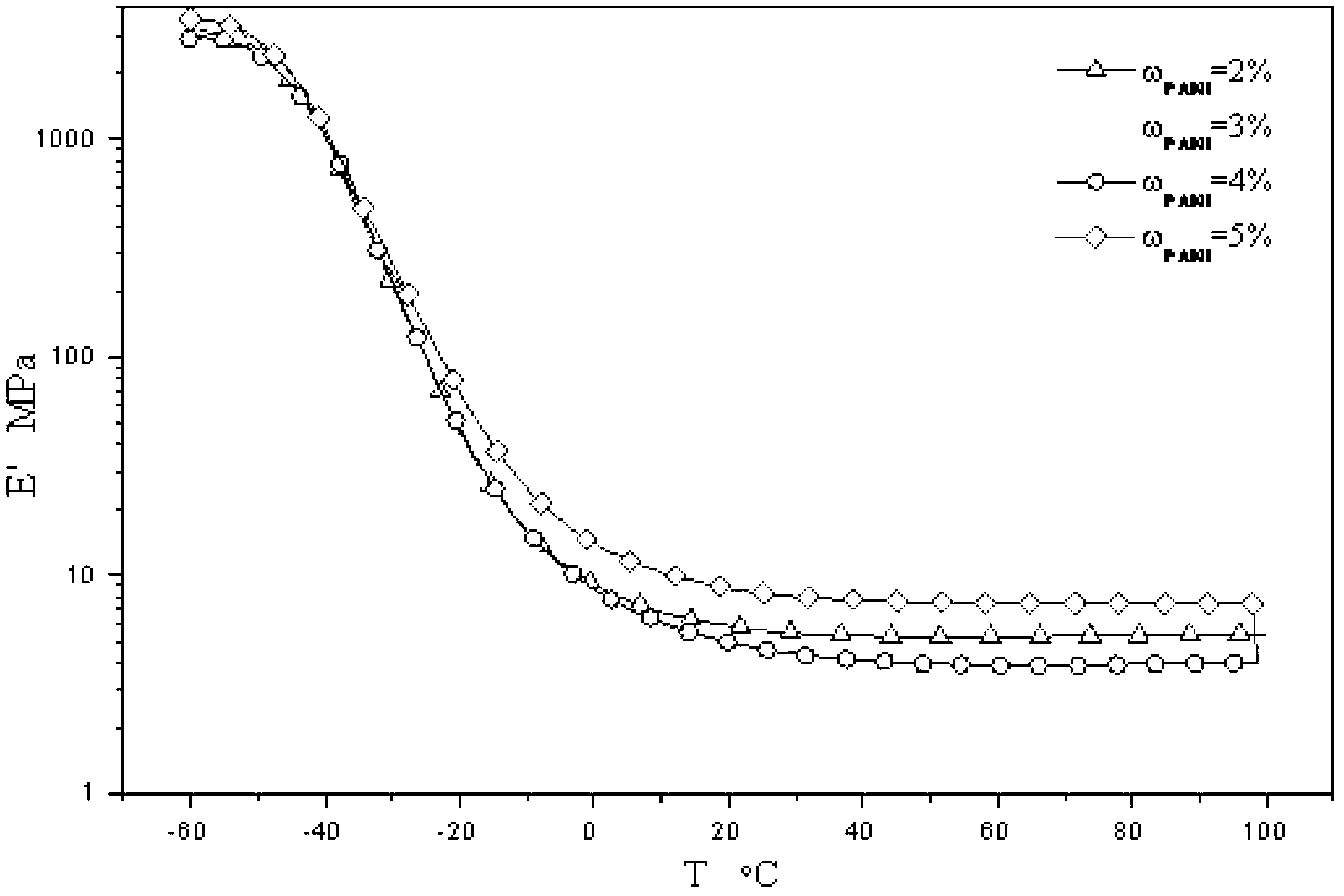

[0063] image 3 Medium ω PANI =3% is the curve of storage modulus versus temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com