Detection method and device for volatile and semi-volatile components

A semi-volatile, detection method technology, applied in the field of chemistry, can solve the problems of unsuitable chromatography mode, unsuitable for volatile components, etc., and achieve the effect of improving analytical sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

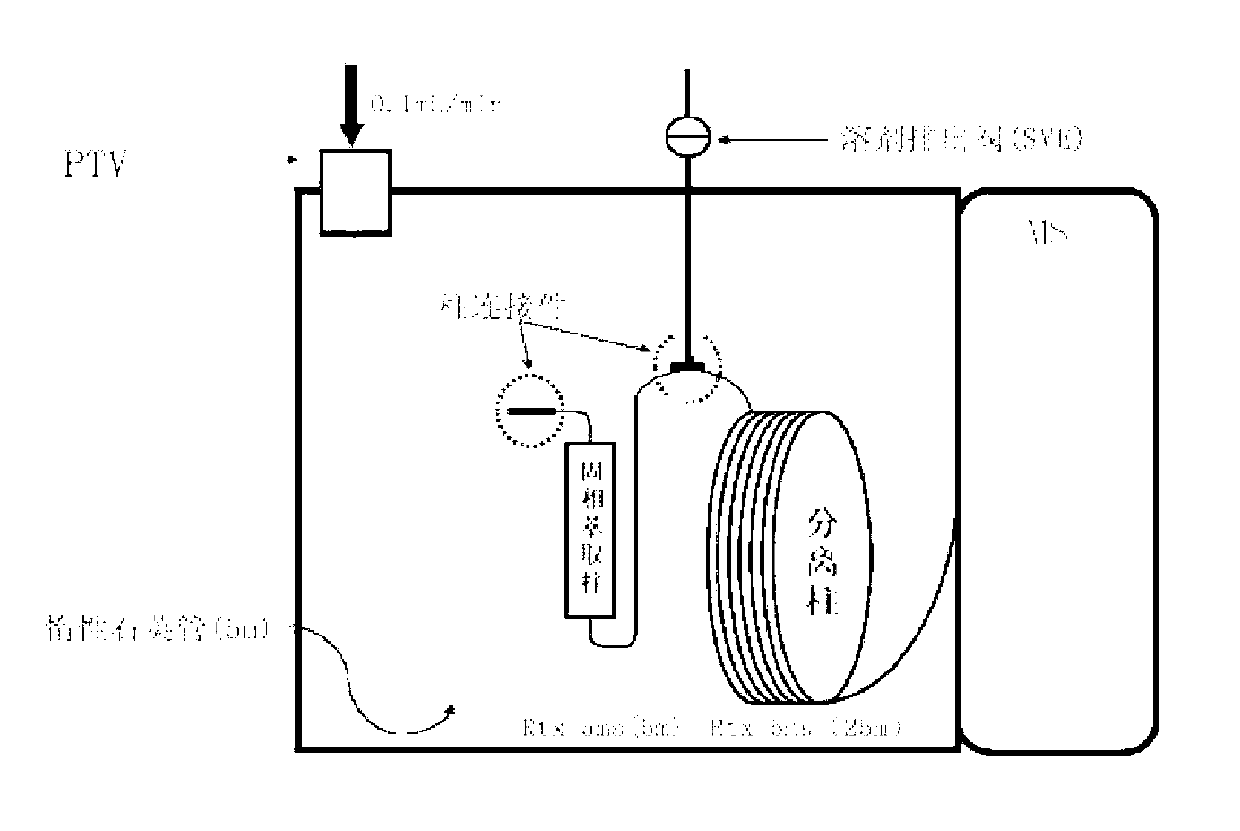

Method used

Image

Examples

Embodiment 1

[0040] Take 20 domestic flue-cured cigarette samples to collect the total particle phase of the smoke according to the method of GB / T 19609-2004, put the obtained filter into the conical flask, and accurately add 1ml of the third-level internal standard with a pipette Solution, accurately add 40ml cyclohexane. Place in an ultrasonic generator for ultrasonic extraction for 40 minutes (ultrasonic frequency 60%), cool to room temperature, take 10 mL of the extract and concentrate it to 1.0 mL, put it into a chromatographic bottle for liquid chromatography separation. Start the liquid chromatograph, the injection volume is 20 μL, the sample enters the liquid chromatographic system, the mobile phase is delivered by pump A and separated by the liquid chromatographic column separation column, and the effluent components of 6 - 6.5 min pass through the digital control six-way The valve cuts into the catch coil and the remainder drains into the waste bottle. Start the pump B, and the ...

Embodiment 2

[0042] Take 20 samples of foreign blended cigarettes and collect the total particulate matter in the smoke according to the method of GB / T 19609-2004, put the obtained filter into the conical flask, and accurately add 1ml of the third-level internal standard with a pipette Solution, accurately add 40ml cyclohexane. Place in an ultrasonic generator for ultrasonic extraction for 40 minutes (ultrasonic frequency 60%), cool to room temperature, take 10 mL of the extract and concentrate it to 1.0 mL, put it into a chromatographic bottle for liquid chromatography separation. Start the liquid chromatograph, the injection volume is 20 μL, the sample enters the liquid chromatographic system, the mobile phase is delivered by pump A and separated by the liquid chromatographic column separation column, and the effluent components of 6 - 6.5 min pass through the digital control six-way The valve cuts into the catch coil and the remainder drains into the waste bottle. Start the pump B, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com