Novel electromagnetic pump

An electromagnetic pump, a new type of technology, applied in the field of electromagnetic pumps, can solve the problems of tension spring processing difficulties, high scrap rate, and consumption of processing time, and achieve simple and convenient production and assembly processes, good product consistency, and improved consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

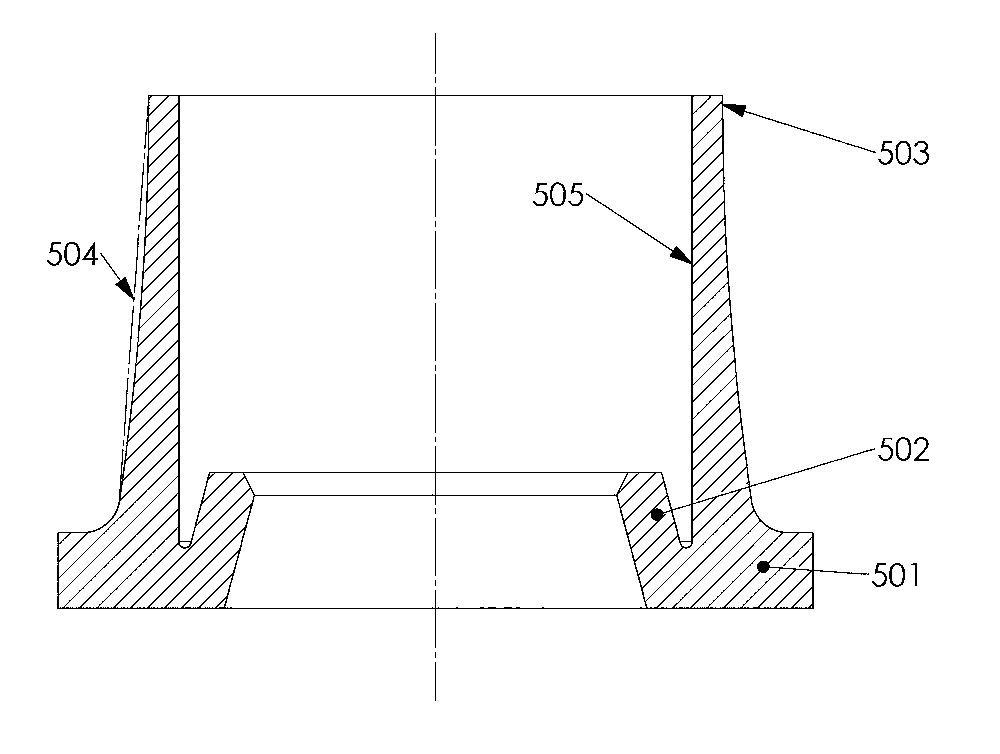

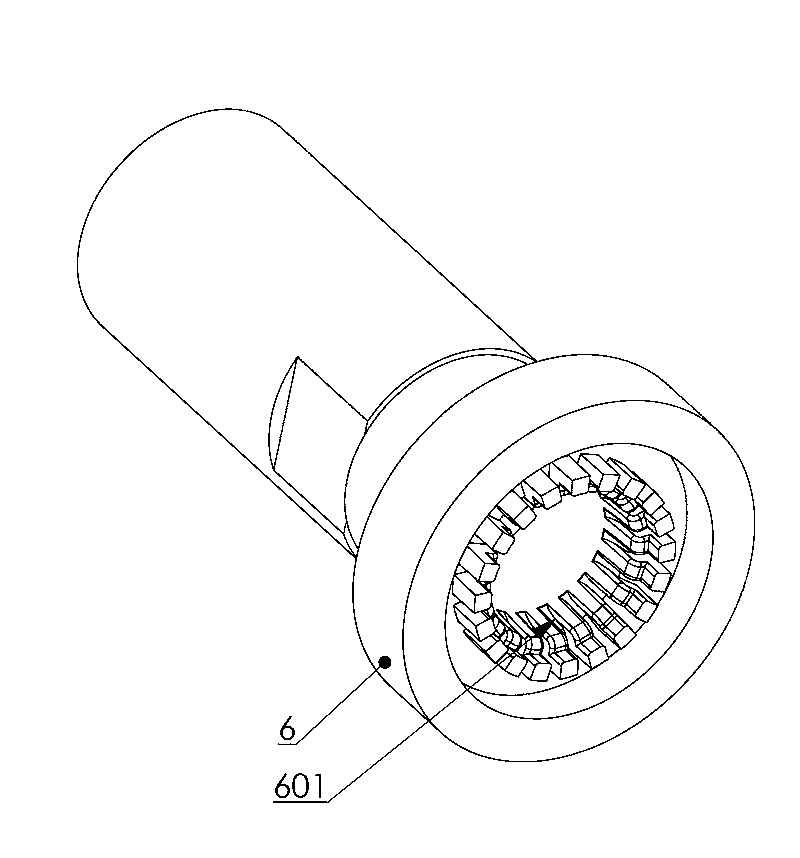

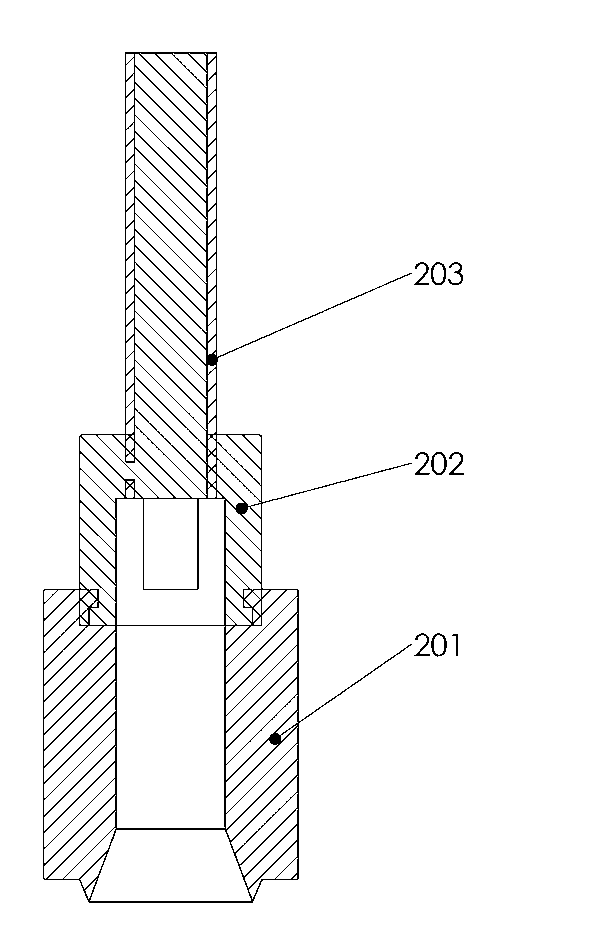

[0025] The technical solution of the present invention will be further described through the following examples in conjunction with the accompanying drawings: a new electromagnetic pump, including a coil assembly 1, a piston assembly 2, a water inlet pipe 3, a positioning sleeve 4, a one-way valve seal 5, and a water outlet 6 , the water outlet check valve 7 and the front and rear springs 8, 9, the coil assembly 1, the water inlet pipe 3, the water outlet check valve 7 and the front and rear springs 8, 9 are manufactured by known public technology, and the slender piston rod 202 part of the piston assembly 2 is Solid, the one-way valve seal 5 of this embodiment is made of rubber material, and its structure is composed of a body 501, an axial sealing part 502, a one-way sealing part 503, a water inlet pressure part 504 and an inner cavity 505:

[0026] Body 501: It is the basic part of the one-way valve seal 5, extending upward is the water inlet pressure part 504, and the insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com