Preparation method of heteropoly acid/metal oxide composite nano fiber

A technology of composite nanofibers and nanofibers, which is applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc. It can solve the problems of difficult to guarantee the quality and stability of the catalyst, the reduction of the specific surface area of the composite material, and the impact on the catalytic activity of heteropolyacids. , to achieve the effect of improving catalytic efficiency, increasing specific surface area and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Weigh 9.0 g of polyvinyl alcohol (PVA), and dissolve it in 100 mL of 2% acetic acid aqueous solution with a volume ratio of 2% in a water bath at 80°C under constant temperature and mechanical stirring to prepare a 9% PVA sol. Mix 1.2 grams of phosphotungstic acid (PWA) with 1.2 grams of Zn(Ac) 2 Dissolve in 10mL deionized water, mix with 30mL of the above PVA sol, and prepare uniform and transparent PWA-Zn(Ac) in a water bath at a constant temperature of 50°C and mechanical stirring 2 - PVA precursor solution.

[0055] Electrospinning technology is used to prepare nanofiber membrane. The spinning voltage was 20 kV, the flow rate of the spinneret solution was 0.6 ml / hour, and the receiving distance was 15 cm. PWA-Zn(Ac) to be received 2 - PVA was heat-treated at 80° C. for 12 hours, and then calcined at 400° C. in an air atmosphere for 2 hours in a tube furnace to obtain PWA-ZnO composite nanofibers.

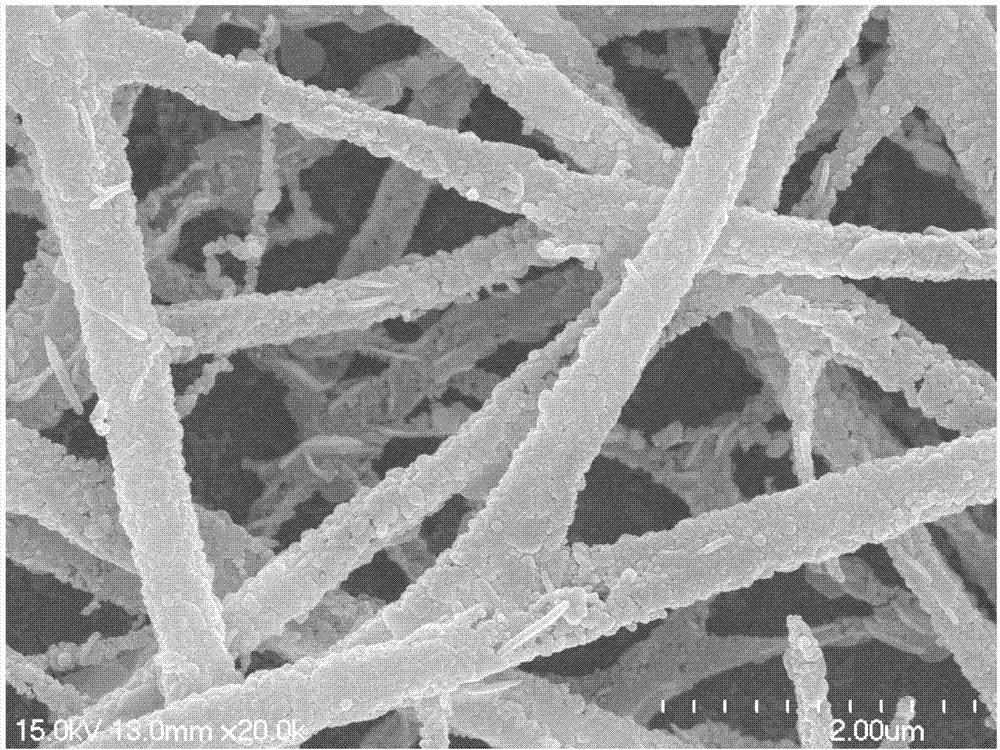

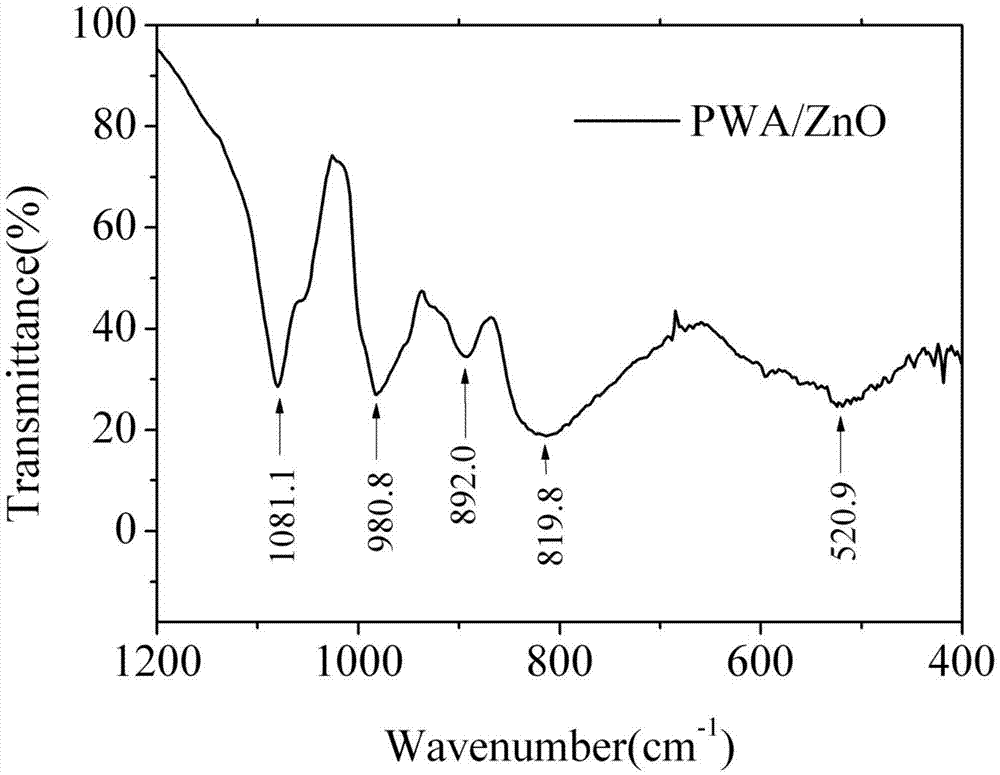

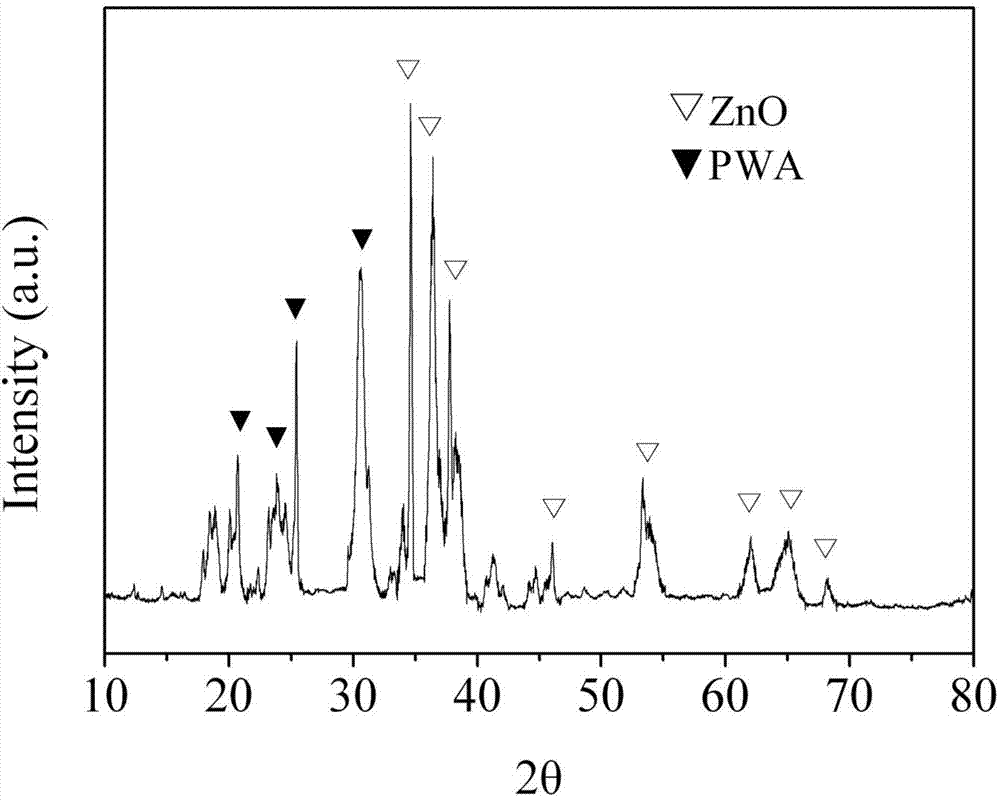

[0056] The scanning electron microscope (SEM) pictures of the ob...

Embodiment 2

[0058] Weigh 9.0 g of polyvinyl alcohol (PVA), and dissolve it in 100 mL of 2% acetic acid aqueous solution with a volume ratio of 2% in a water bath at 80°C under constant temperature and mechanical stirring to prepare a 9% PVA sol. Mix 1.0g of silicotungstic acid (HSiW) with 1.2g of Zn(Ac) 2 Dissolve in 10mL deionized water, mix with 30mL of the above PVA sol, and prepare uniform and transparent HSiW-Zn(Ac) in a water bath at a constant temperature of 50°C and mechanical stirring 2 - PVA precursor solution.

[0059] Electrospinning technology is used to prepare nanofiber membrane. The spinning voltage was 20 kV, the flow rate of the spinneret solution was 0.6 ml / hour, and the receiving distance was 15 cm. HSiW-Zn(Ac) to be received 2 -PVA was heat-treated at 80°C for 12 hours, and then fired in an air atmosphere at 400°C for 2 hours in a tube furnace to obtain HSiW-ZnO composite nanofibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com