Extraction kettle apparatus for separating coal tar through mild extraction method

A technology of extraction kettle and extraction method, which is applied in the field of extraction kettle equipment for the separation of coal tar by mild extraction method, and achieves the effects of high separation efficiency, less exhaust gas emission and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

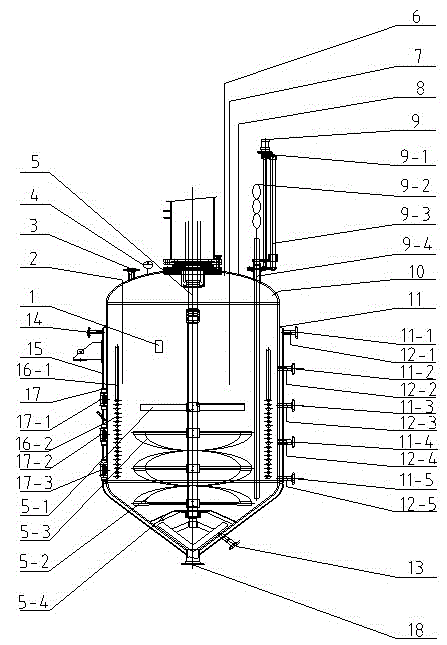

[0026] Embodiment 1: The extraction kettle equipment includes: a kettle body 1, a temperature measuring thermocouple temperature measuring port 2, a feed port 3 for raw materials and extractant, a pressure gauge pressure measuring port 4, a sealed strong magnetic stirrer 5. A divergence port 6, a nitrogen inlet 7, a nitrogen outlet 8, a set of top electric lifting riser light component discharge system 9, a set of side light component discharge system controlled by a group of lower expansion valves 11 , a solvent and extractant feed port 10, a set of glass sight cups 12, a heating steam coil steam inlet 14, a heating steam coil steam outlet 13, an additional cover 15 for the extraction kettle, and two hot steam heating coils , three sets of mirrors, a heavy asphalt outlet 18 and corresponding pipelines and valves;

[0027] A powerful magnetic stirrer 5 is arranged in the center of the upper cover, and the strong magnetic stirrer 5 is sealed with the upper cover, and a temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com