Co-Zn-Cr-Al composite spinel type blue ceramic pigment and preparation method thereof

A ceramic colorant and spinel-type technology, applied in the field of ceramic color glaze, can solve the problems that ceramic inkjet printing decoration cannot be applied, difficulty in meeting ceramic colorant, and difficulty in batch production, etc., and is conducive to large-scale promotion and application, easy to control and realize, shape controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

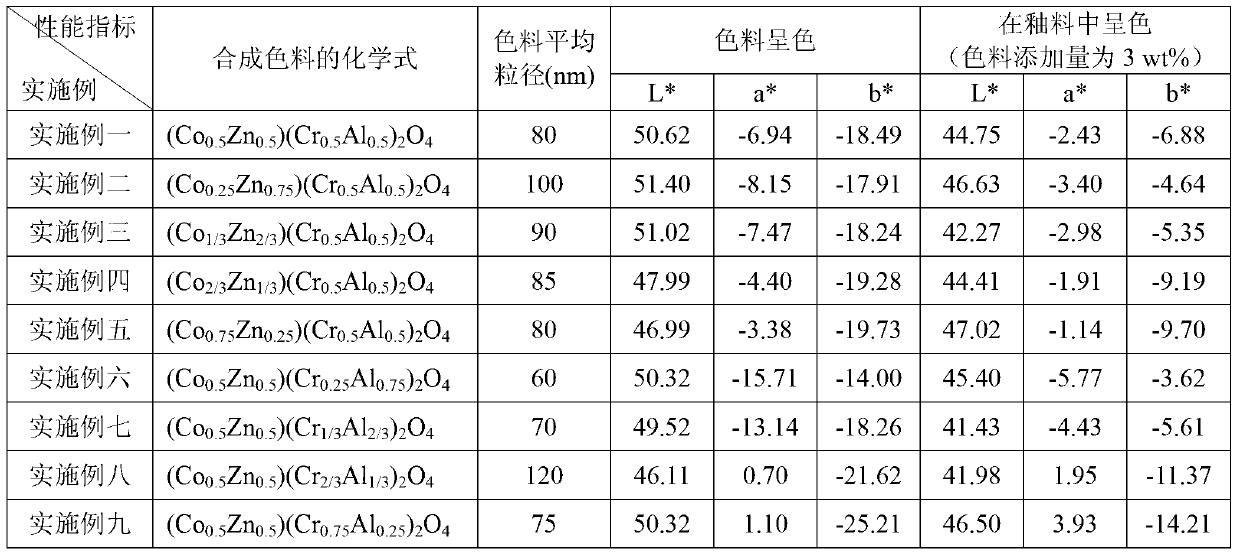

Examples

Embodiment 1

[0031] This embodiment (Co 0.5 Zn 0.5 )(Cr 0.5 al 0.5 ) 2 o 4 The preparation method of composite spinel type blue ceramic pigment, its step is as follows:

[0032] (1) according to the parameter in above-mentioned chemical reaction formula and table 1, take by weighing cobalt nitrate, zinc nitrate, chromium nitrate, aluminum nitrate respectively by respective stoichiometric ratio, sucrose is weighed by 150wt% of its stoichiometric ratio, chlorination Na (Co 0.5 Zn 0.5 )(Cr 0.5 al 0.5 ) 2 o 4 50wt% of the theoretical synthesis amount was weighed; each raw material was dissolved in distilled water, and magnetically stirred for 60 minutes to mix evenly, and the Co in the mixed solution 2+ +Zn 2+ The ion concentration is 0.3mol / L;

[0033] (2) Put the above mixed solution in a heat-resistant crucible, ignite and burn it in a muffle furnace at a temperature of 500 ° C, and keep it warm for 10 minutes after burning to obtain a product precursor;

[0034](3) The precur...

Embodiment 2

[0037] This embodiment (Co 0.25 Zn 0.75 )(Cr 0.5 al 0.5 ) 2 o 4 The preparation method of composite spinel type blue ceramic pigment, its step is as follows:

[0038] (1) according to the parameter in above-mentioned chemical reaction formula and table 1, take cobalt nitrate, zinc nitrate, chromium nitrate, aluminum nitrate respectively by respective stoichiometric ratio, sucrose is weighed by its 125wt% by stoichiometric ratio, chlorine NaCl (Co 0.25 Zn 0.75 )(Cr 0.5 al 0.5 ) 2 o 4 30wt% of the theoretical synthesis amount was weighed; each raw material was dissolved in distilled water, and magnetically stirred for 45 minutes to mix evenly, and the Co in the mixed solution 2+ +Zn 2+ The ion concentration is 0.4mol / L;

[0039] (2) Put the above mixed solution in a heat-resistant crucible, ignite and burn it in a muffle furnace at a temperature of 400 ° C, and keep it warm for 15 minutes after burning to obtain a product precursor;

[0040] (3) The above-mentioned...

Embodiment 3

[0043] This embodiment (Co 1 / 3 Zn 2 / 3 )(Cr 0.5 al 0.5 ) 2 o 4 The preparation method of composite spinel type blue ceramic pigment differs from embodiment one in that:

[0044] In step (1), each raw material is dissolved in distilled water, and magnetically stirred for 30 minutes to mix evenly, and in the mixed solution

[0045] co 2+ +Zn 2+ The ion concentration is constant at 0.5mol / L;

[0046] In step (3), the product precursor is calcined at a temperature of 1150° C., kept for 60 minutes, and cooled with the furnace to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com