Function ceramic material for efficiently filtering radioactive iodine and cesium, and preparation method thereof

A technology of radioactive iodine and functional ceramics, which is applied in the production of ceramic materials, ceramic products, clay products, etc., can solve the problem of less radioactive iodine filtration materials and technologies, low selectivity of zeolite filter materials, ammonium phosphomolybdate grains If it is too small, it can achieve strong ion exchange and immobilization capacity, increase porosity, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

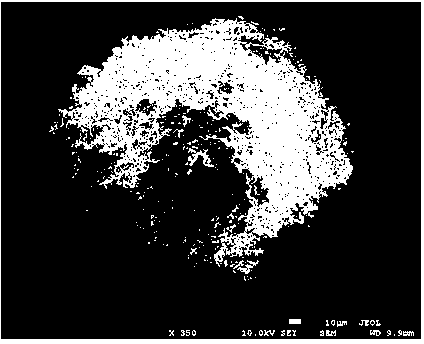

Image

Examples

Embodiment 1

[0029] Weigh the raw materials according to the following proportions,

[0030] Sludge 40 Kg, clay (kaolin) 40 Kg, calcium carbonate 12 Kg, sawdust 8 Kg, liquid paraffin 5 Kg, iron oxide powder 6 Kg.

[0031] The preparation steps are as follows:

[0032] (1) According to the above formula, the raw materials are fully mixed and stirred to make a slurry, and the slurry is made into spherical particles with a diameter of 4 mm by a granulator, and dried to form a billet;

[0033] (2) Place the mud body prepared in step (1) in a high-temperature sintering furnace, 2 Firing under the atmosphere, when the temperature is raised from 80°C per hour to 550°C, keep it for 2 hours, then continue to heat up at a rate of 100°C per hour, until it reaches 1050°C, keep it for 4 hours, stop heating, and keep it at a rate of 150°C per hour The furnace temperature was lowered to room temperature to obtain a porous ceramic material with a diameter of 2 mm.

Embodiment 2

[0035] Weigh the raw materials according to the following proportions,

[0036] Sludge 40 Kg, clay (bentonite) 30 Kg, calcium carbonate 11 Kg, activated carbon 5 Kg, liquid paraffin 3 Kg, iron oxide powder 6 Kg.

[0037] The preparation steps are as follows:

[0038] (1) According to the above formula, the raw materials are fully mixed and stirred to make a slurry, and the slurry is made into spherical particles with a diameter of 4 mm by a granulator, and dried to form a billet;

[0039] (2) Place the mud body prepared in step (1) in a high-temperature sintering furnace, 2 Firing under atmosphere, when the temperature rises from 80°C per hour to 550°C, keep it for 2 hours, then continue to heat up at a rate of 100°C per hour, until it reaches 1100°C, keep it for 3 hours, stop heating, and keep it at a rate of 150°C per hour The furnace temperature was lowered to room temperature to obtain a porous ceramic material with a diameter of 5 mm.

Embodiment 3

[0041] The raw materials are weighed according to the following proportioning ratio, and the consumption of each composition is parts by weight:

[0042] Sludge 40 Kg, clay (activated clay) 20 Kg, calcium carbonate 13 Kg, sawdust 7 Kg, liquid paraffin 2 Kg, iron powder 5 Kg.

[0043] The preparation steps are as follows:

[0044] (1) According to the above formula, the raw materials are fully mixed and stirred to make a slurry, and the slurry is made into spherical particles with a diameter of 4 mm by a granulator, and dried to form a billet;

[0045] (2) Place the mud body prepared in step (1) in a high-temperature sintering furnace, under N 2 Firing under the atmosphere, when the temperature is raised from 80°C per hour to 600°C, keep it for 2 hours, then continue to heat up at a rate of 100°C per hour, until it reaches 1050°C, keep it for 4 hours, stop heating, and keep it at a rate of 200°C per hour The furnace temperature was lowered to room temperature to obtain a poro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com