Pipeline descaling device

A pipeline and steel pipe technology, applied in the direction of light water/sewage treatment, etc., can solve the problems of serious pollution, high cost, and environmental damage, and achieve the effects of reducing energy consumption, reducing viscosity, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

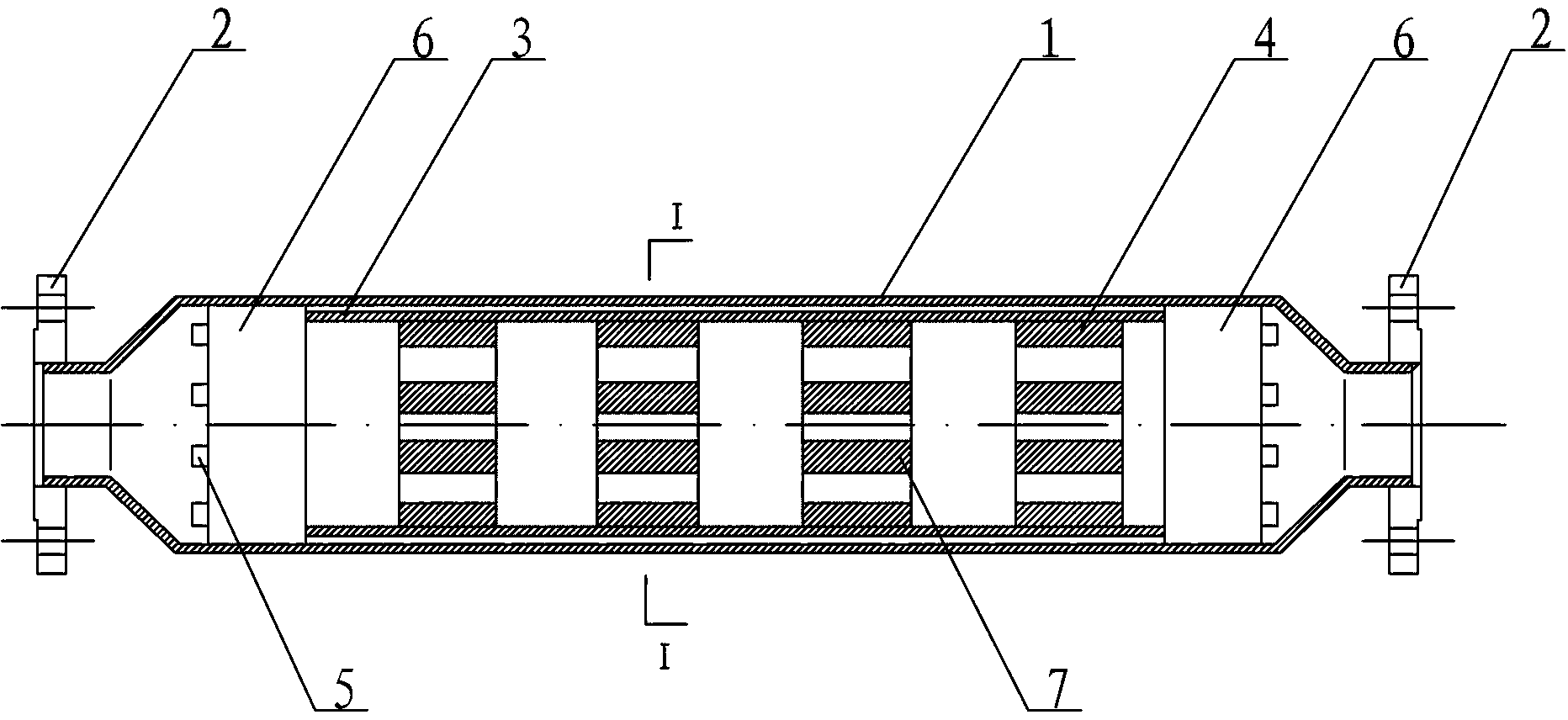

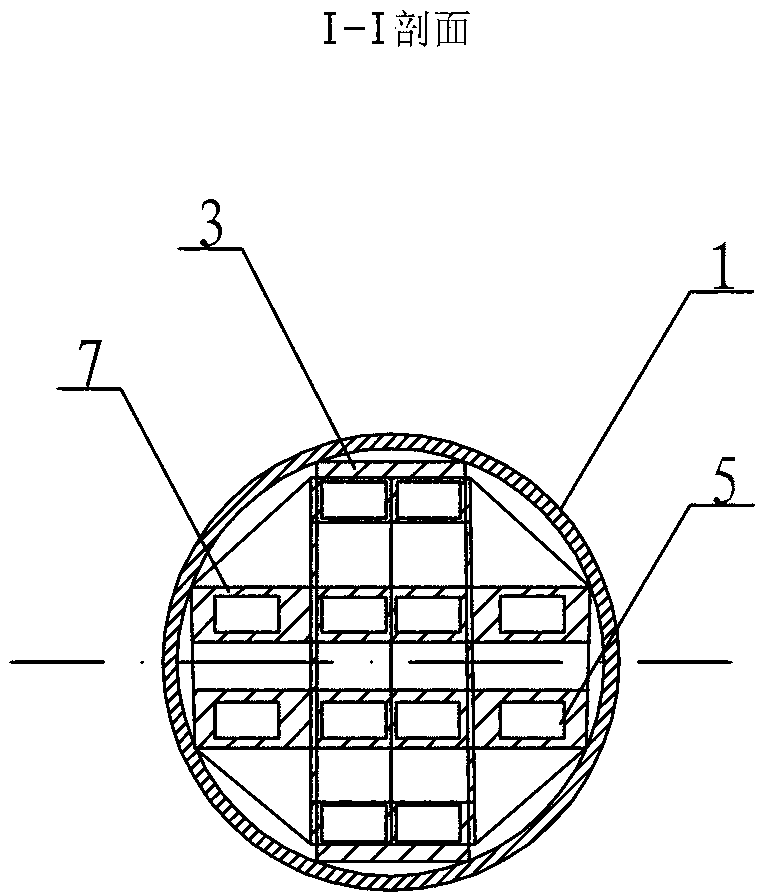

[0010] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, this embodiment comprises casing 1 and two flanges 2, and two flanges 2 are arranged at the two ends of casing 1 respectively, and described descaling device also comprises fixed plate 3, multiple combination gold blocks 4 and multiple A stainless steel pipe 5, the fixed plate 3 is arranged in the shell 1, and the multi-combined gold nuggets 4 are arranged in the shell 1 at equal intervals from left to right, and the upper end and the lower end of each combined gold nugget 4 are connected with the fixed plate 3 respectively. The stainless steel pipe 5 is pierced on the multi-combination gold nugget 4 along the length direction of the casing 1 .

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 To describe this embodiment, the number of alloy nuggets 4 in this embodiment is 3-6 groups. Such setting makes it easy to select an appropriate number of alloy nuggets 4 according to the amount of water to be treated and the quality of the water to be treated in different enterprises. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 1 The present embodiment will be described, and the number of alloy lumps 4 in the present embodiment is four groups. Such a setting is the best for water quality treatment of small and medium-sized enterprises. Other compositions and connections are the same as those in the second embodiment.

[0013] Specific implementation mode four: combination figure 1 and figure 2 To describe this embodiment, the multi-combination gold nuggets 4 of this embodiment are all boron-iron-magnesium alloys. Such arrangement facilitates the function of anti-scaling. Other compositions and connections are the same as those in the third embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com