S-shaped aerosol extinguishing agent and preparation method thereof

A technology of fire extinguishing agent and aerosol, which is applied in the direction of fire prevention equipment, etc., can solve the problems of high aerosol temperature, unstable fire extinguishing agent combustion, and large aerosol buoyancy, and achieve low reaction temperature, good insulation, and reaction temperature fluctuation range Falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

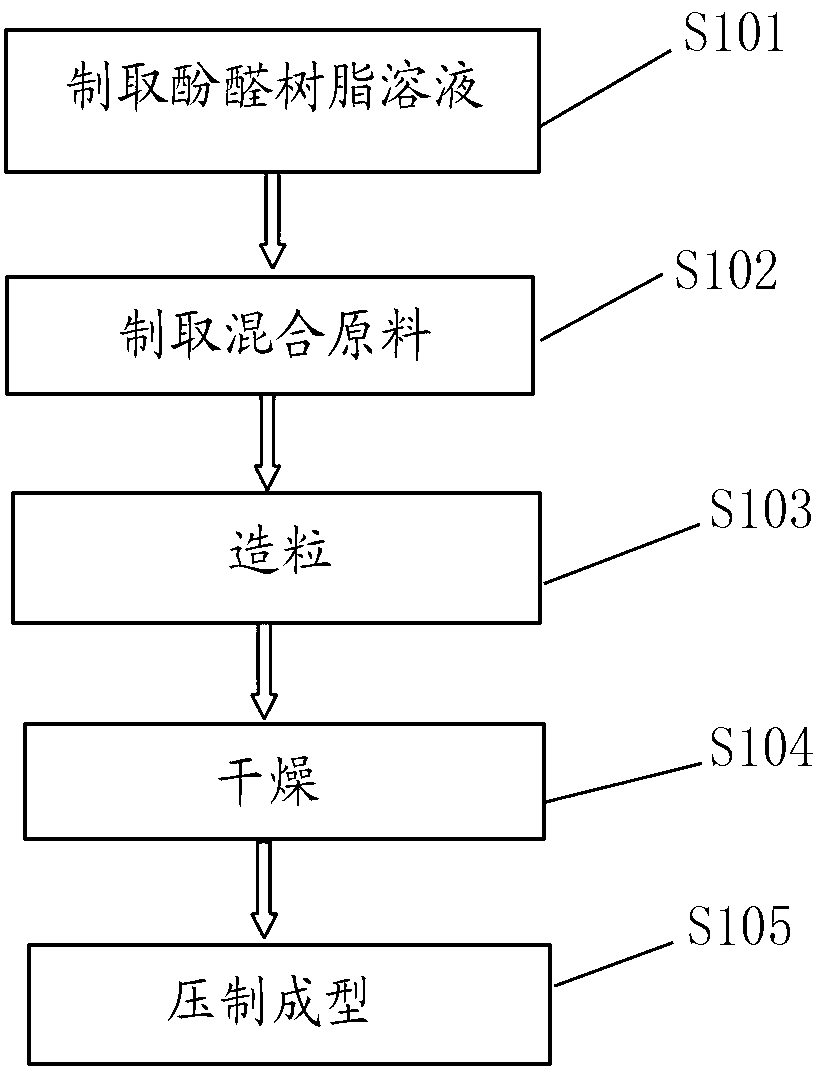

[0038] like figure 1 As shown, it shows that the specific process of the S-type aerosol fire extinguishing agent is:

[0039] S101 preparing phenolic resin solution: take phenolic resin by weighing 7 parts by weight of phenolic resin, dissolve in ethanol, make the phenolic resin solution that mass concentration is 45%;

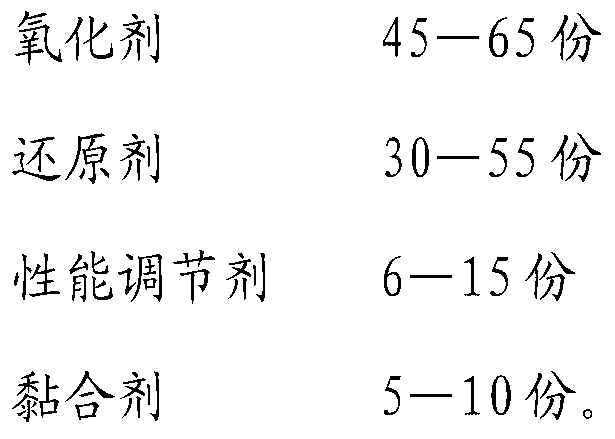

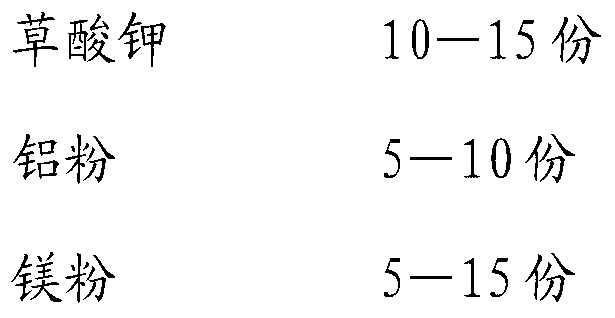

[0040] S102 Preparation of mixed raw materials: 35 parts of strontium nitrate, 10 parts of potassium nitrate, 6 parts of magnesium nitrate, 12 parts of potassium oxalate, 5 parts of aluminum powder, 7 parts of magnesium powder, 5 parts of sucrose, 5 parts of urea, 2 parts of charcoal powder, 2 parts of basic magnesium carbonate, 2 parts of hexamethylenetetramine, and 2 parts of azodicarbonamide were dried, mixed uniformly, pulverized, and filtered through a 200-mesh sieve to obtain mixed raw materials;

[0041] S103 Granulation: Add the phenolic resin solution to the mixed raw materials, stir evenly, and then use a 40-mesh screen to granulate.

[0042] S104 ...

Embodiment 2

[0045] Prepare the phenolic resin solution: take the phenolic resin by weighing 5 parts by weight of the phenolic resin, dissolve it in ethanol, and make a phenolic resin solution with a mass concentration of 40%;

[0046] Preparation of mixed raw materials: Take 25 parts of strontium nitrate, 15 parts of potassium nitrate, 8 parts of magnesium nitrate, 10 parts of potassium oxalate, 8 parts of aluminum powder, 10 parts of magnesium powder, 6 parts of sucrose, 5 parts of urea, 2 parts of charcoal powder, alkali 2 parts of formula magnesium carbonate, 2 parts of hexamethylenetetramine, 2 parts of azodicarbonamide, dry, mix uniformly, pulverize, then filter with a particle diameter of 200 mesh sieves to obtain mixed raw materials;

[0047] Granulation: Add the phenolic resin solution to the mixed raw materials, stir evenly, and then use a 40-mesh screen to granulate.

[0048] Drying: Place the granulated material in an electric blast drying oven at 60°C and a relative humidity o...

Embodiment 3

[0051] Prepare the phenolic resin solution: take the phenolic resin by weighing 6 parts by weight of the phenolic resin, dissolve it in ethanol, and make a phenolic resin solution with a mass concentration of 45%;

[0052]Preparation of mixed raw materials: 30 parts of strontium nitrate, 8 parts of potassium nitrate, 8 parts of magnesium nitrate, 10 parts of potassium oxalate, 6 parts of aluminum powder, 10 parts of magnesium powder, 12 parts of sucrose, 2 parts of charcoal powder, 4 parts of basic magnesium carbonate 2 parts, 2 parts of hexamethylenetetramine, 2 parts of azodicarbonamide, dry, mix uniformly, pulverize, and then filter with a particle diameter of 200 mesh sieves to obtain mixed raw materials;

[0053] Granulation: Add the phenolic resin solution to the mixed raw materials, stir evenly, and then use a 40-mesh screen to granulate.

[0054] Drying: Place the granulated material in an electric blast drying oven at 60°C and a relative humidity of not more than 30%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com