Linear polyethylene glycol fragrance slow-release cigarette filter rod and production method thereof

A polyethylene glycol, cigarette filter rod technology, applied in the preparation of tobacco, smoke oil filter, tobacco and other directions, can solve the problems of uneven release of fragrance substances, less adsorption of fragrance substances, short fragrance retention time, etc., to achieve fragrance retention. The effect of long time, uniform release and low adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

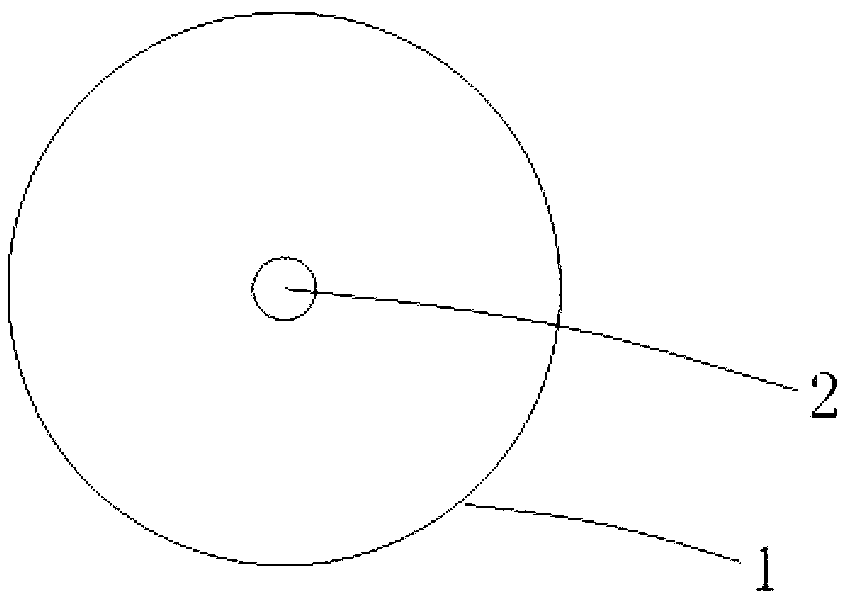

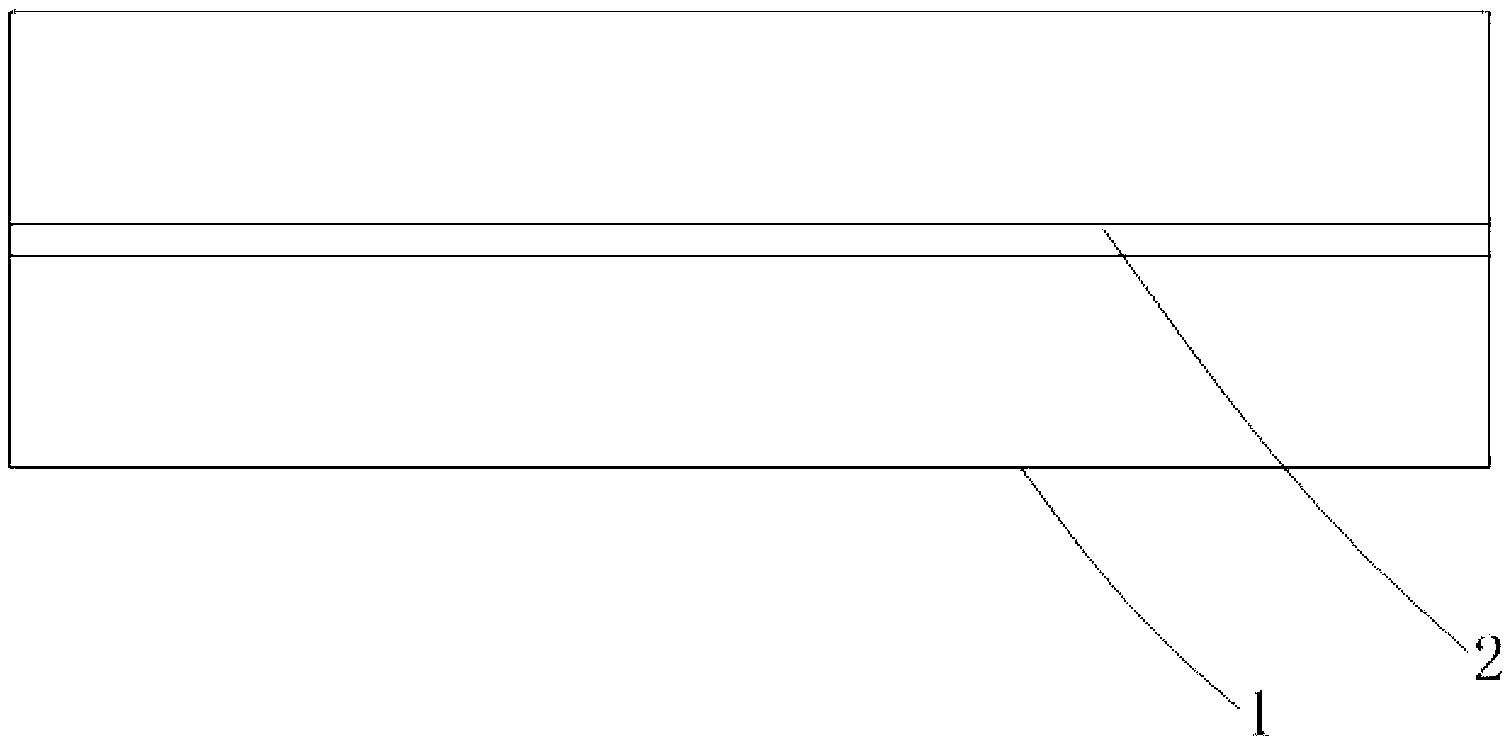

[0015] Example: Combine figure 1 , 2 , the linear polyethylene glycol fragrance slow-release cigarette filter stick described in this embodiment is provided with polyethylene glycol flavoring thread along the axial direction of the filter stick in the filter stick, and the polyethylene glycol flavoring thread is used to The fragrance substance of phenethyl alcohol is embedded in the fragrance thread as a carrier. The diameter of the polyethylene glycol fragranced thread is 0.5mm.

[0016] The preparation method of the linear polyethylene glycol flavor slow-release cigarette filter rod of the present invention comprises the following steps:

[0017] First, polyethylene glycol is heated to 60-80°C to make it completely melted, and the phenylethanol fragrance substance is added in a proportion of 5% by weight, and stirred evenly; (phenylethanol accounts for 5% of the total amount of polyethylene glycol and phenylethanol ), and then pass the liquid polyethylene glycol containin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com