Preparation method of mesophase pitch carbon microsphere and application thereof in negative electrode material of lithium battery

A technology of mesophase pitch and carbon microspheres, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low yield, high yield, wide ball diameter distribution, etc., and achieve low capacity decay rate and good rate performance , the effect of uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Centrifuge the pulverized asphalt raw material particles with a particle size of 1-30 μm at a speed of 2000r / min for 5 minutes to separate the raw material particles with a particle size of 1-2 μm, take 1g of the raw material particles, and disperse them evenly in 20ml of petroleum ether Then add this asphalt petroleum ether mixture into 100ml of high temperature resistant silicone oil, keep stirring at a speed of 300r / min for 5min; while continuing to stir, stop heating when the system is rapidly heated to 270°C, and naturally cool to room temperature; use high-speed centrifugation The product pellets were centrifuged and washed with petroleum ether to obtain pure mesophase pitch microspheres with small particle size.

[0017] In a blast oven, pre-oxidize at 150°C for 6 hours, 250°C for 6 hours, then carbonize at 1000°C for 1 hour, and graphitize at 2800°C for 1 hour to obtain mesophase carbon microspheres with a particle size of 1-2 μm.

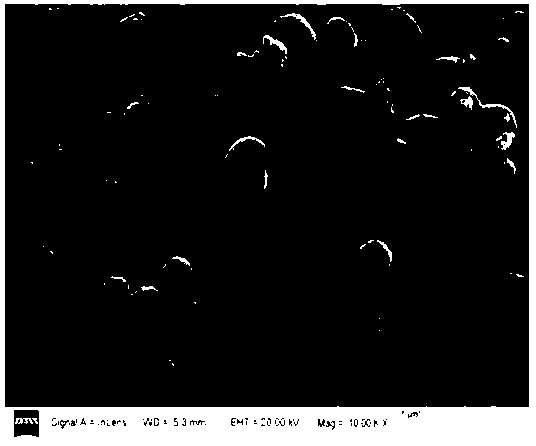

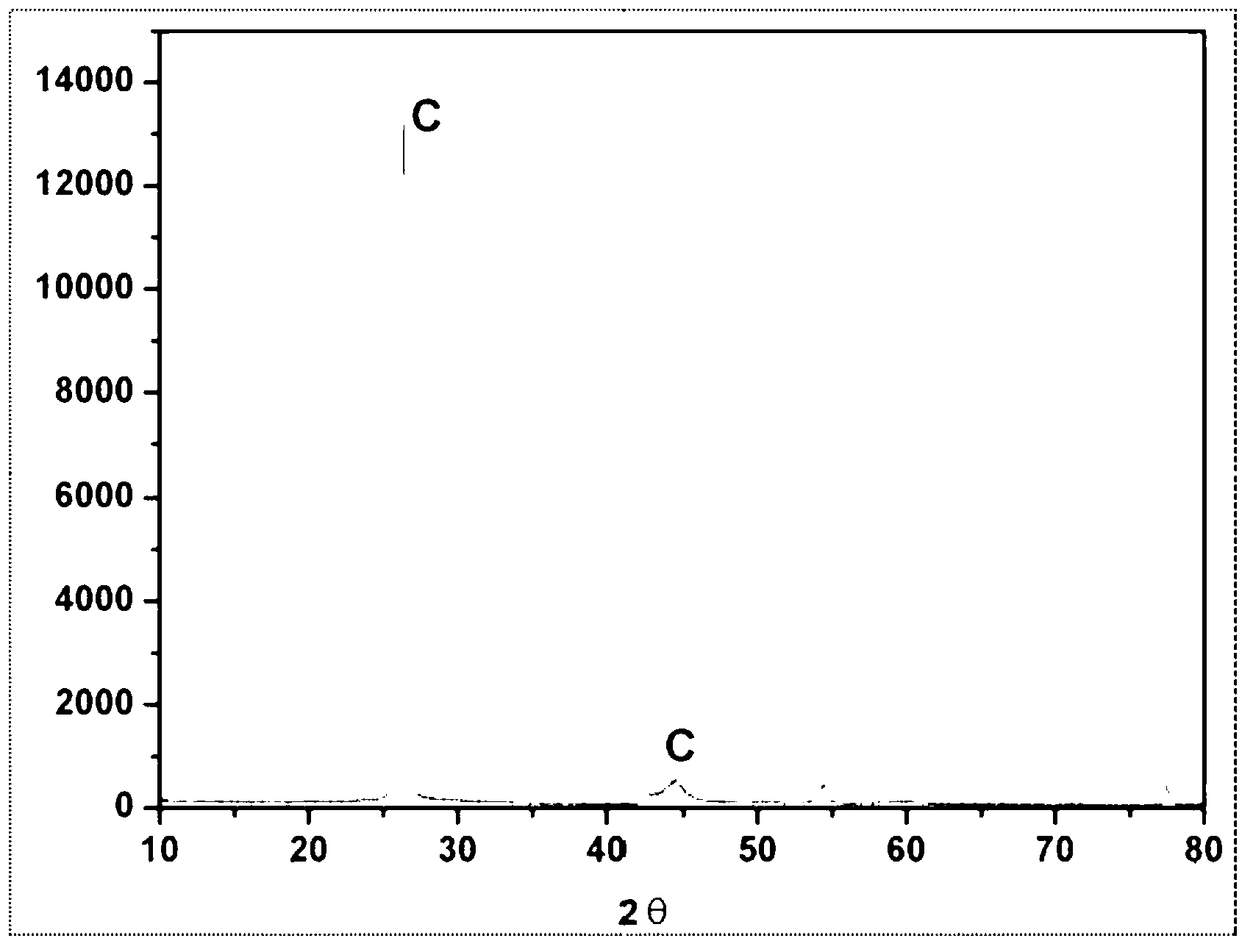

[0018] as attached figure 1 ...

Embodiment 2

[0020] The preparation method is the same as in Example 1, except that the raw material particles with a particle size of 3-30 μm (in Example 1, the raw material particles with a particle size of 1-2 μm were removed) were centrifuged at 1500 r / min for 5 minutes to separate the particles with a particle size of 3 -5μm mesophase pitch particles, stop heating when the system rapidly heats up to 260°C,

[0021] In a blast oven, pre-oxidize at 200°C for 4 hours, 300°C for 4 hours, carbonize at 1000°C for 1 hour, and graphitize at 2800°C for 1 hour to obtain mesophase carbon microspheres with a particle size of 3-5 μm.

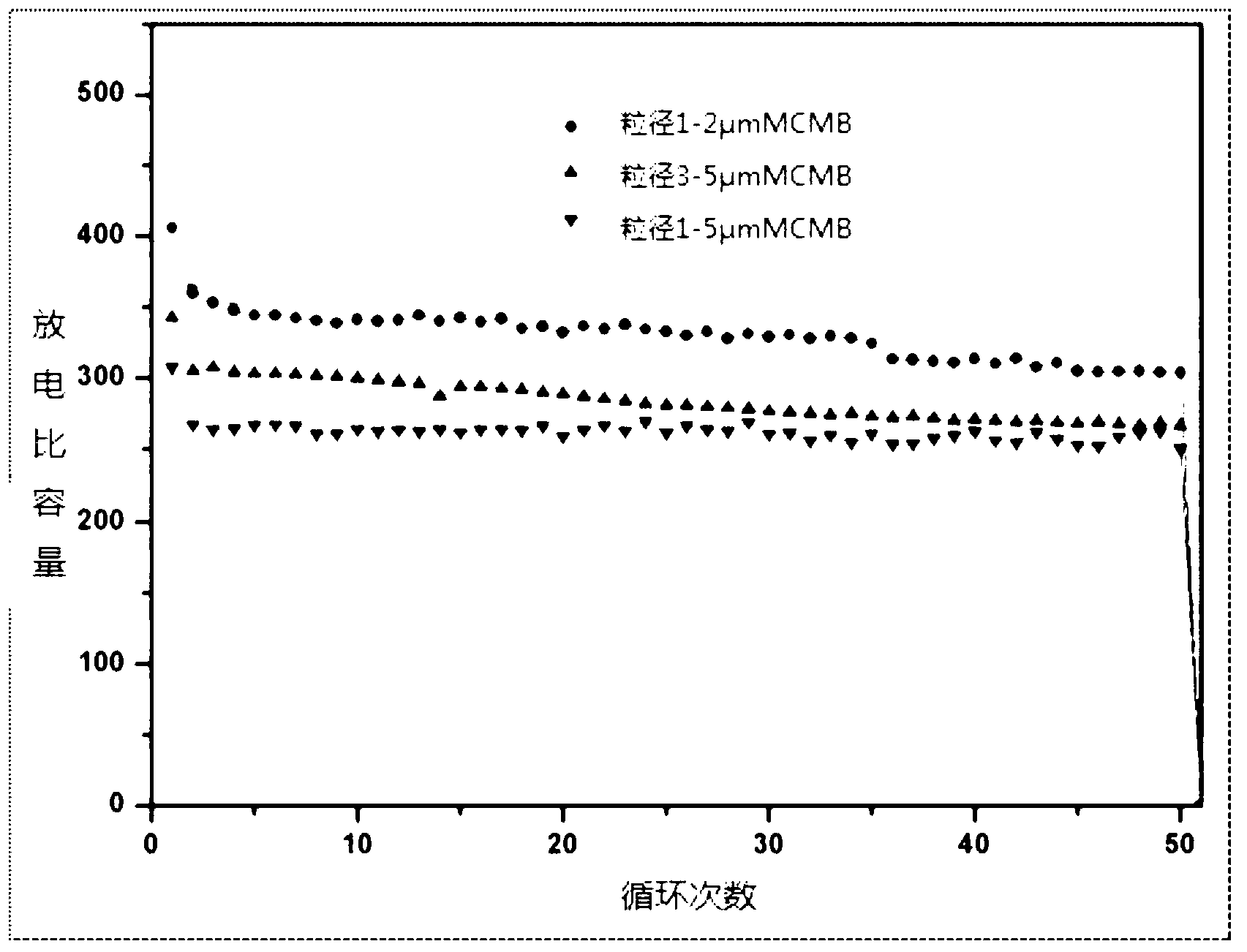

[0022] as attached image 3 The electrochemical performance test results show that the battery is stable at about 300mAh / g after 50 cycles; Figure 4 As shown in the charge and discharge rate performance diagram, the average discharge specific capacity of 50mA / g is 305.3mAh / g, the average discharge specific capacity of 100mA / g is 218.3mAh / g, 200mA / g, the average di...

Embodiment 3

[0024] The preparation method is the same as in Example 1, except that the pulverized asphalt raw material particles with a particle size of 1-30 μm are centrifuged at 1000 r / min for 5 minutes to separate the raw material particles with a particle size of 1-5 μm, and finally obtain a particle size of 1-5 μm Mesophase carbon microspheres.

[0025] as attached image 3 The electrochemical performance test results show that the battery is stable at about 300mAh / g after 50 cycles; Figure 4 As shown in the charge and discharge rate performance diagram, the average discharge specific capacity of 50mA / g is 379.3mAh / g, the average discharge specific capacity of 100mA / g is 341.8mAh / g, 200mA / g, the average discharge specific capacity is 248.3mAh / g, 400mA / g, The average discharge specific capacity is 122.4mAh / g. Due to the existence of 1-2μm particles, the charge-discharge specific capacity is high under high current density, the rate performance is good, and it still maintains a high ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com