Preparation method of diffusion impervious layer free Cu(Ru) alloy material with high thermal stability

A high thermal stability, alloy material technology, applied in metal material coating process, coating, ion implantation plating, etc., can solve the problem of affecting the electrical properties of copper interconnection structure, surface roughness of barrier layer material, copper interconnection structure size Small problems, to achieve high-performance diffusion barrier properties, simple and easy to control method, and stable deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

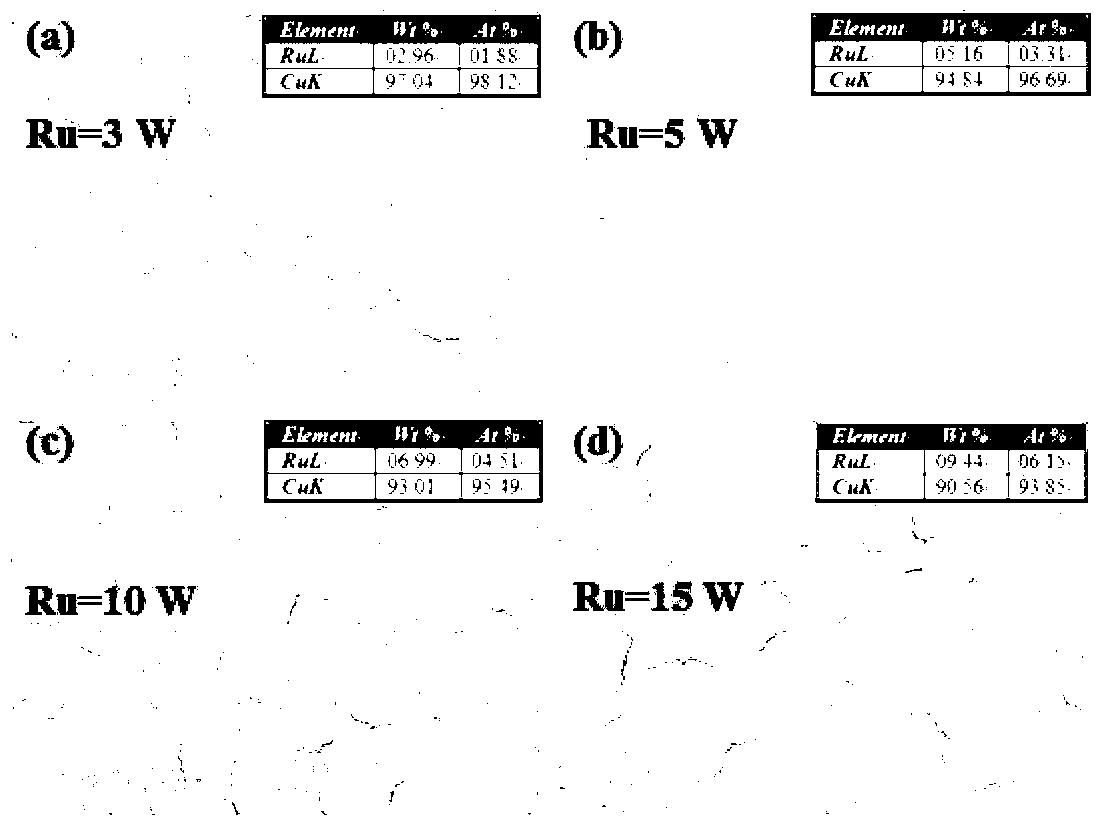

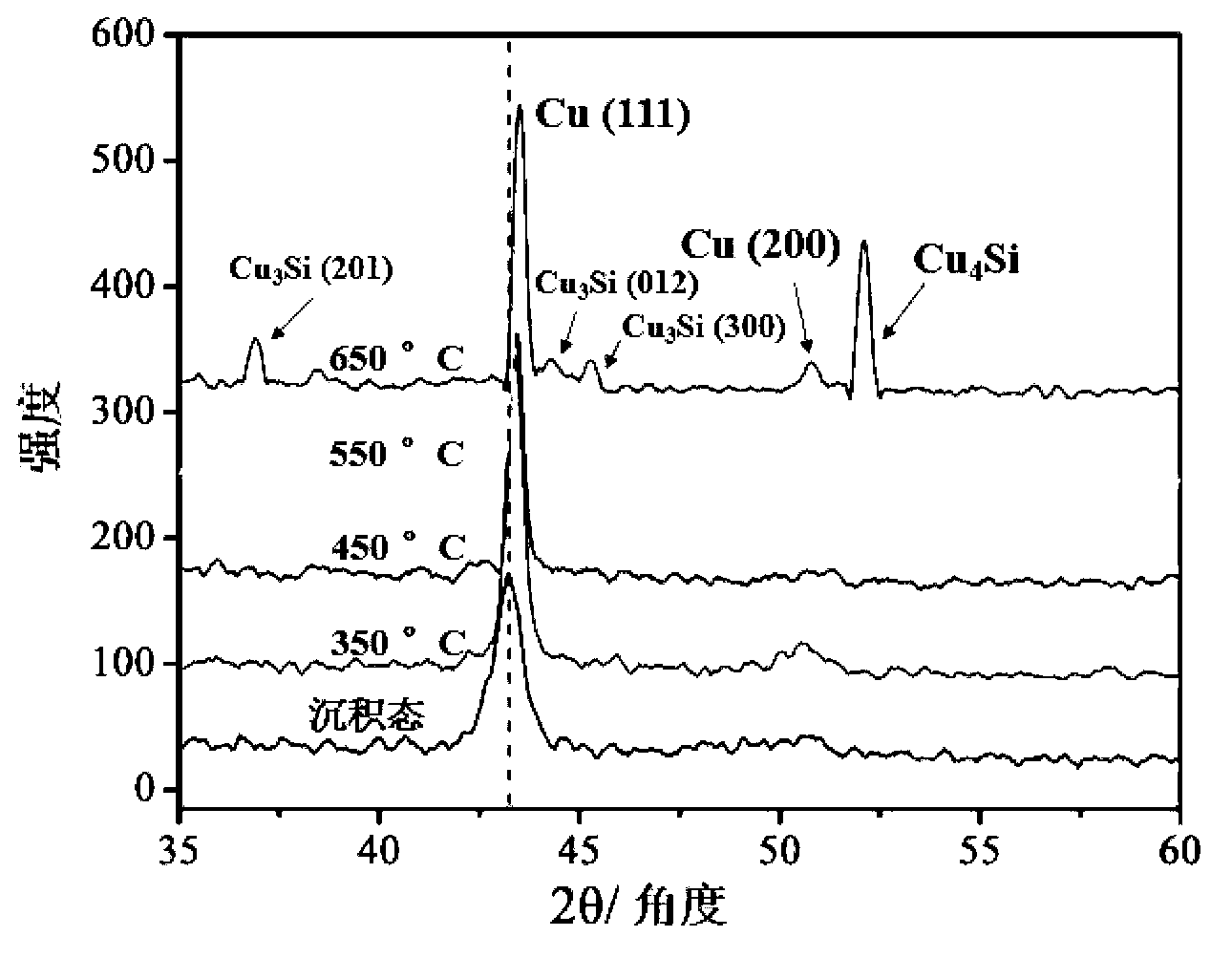

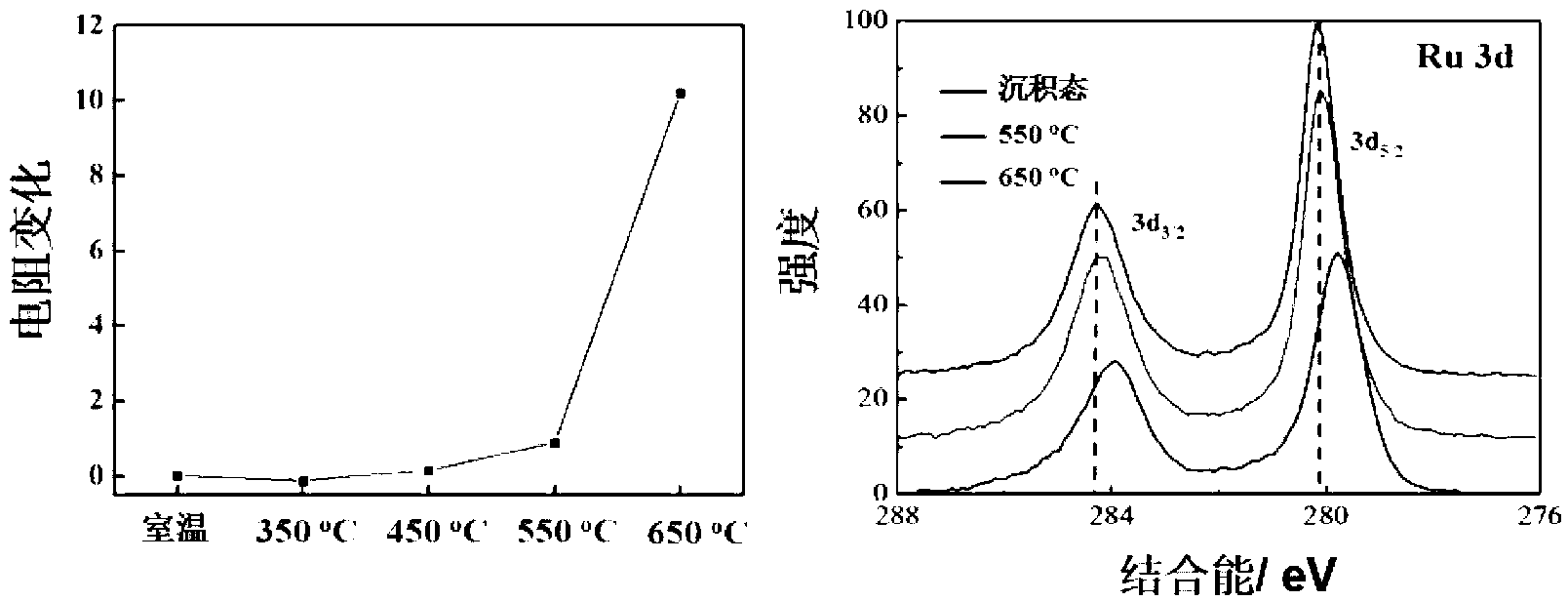

[0023] Cu(Ru) alloy materials with different Ru content were prepared by DC magnetron sputtering method. A JGP450 magnetron sputtering apparatus used a permanent magnet target with a diameter of 75mm and only DC power supply was applied. The maximum sputtering power was 500W. A sample turntable with self-rotation function, the sample can be heated or water-cooled, the maximum temperature can reach 550°C, and the heating rate can be adjusted from 10°C / min to 40°C / min. The three targets are confocal on the sample stage, which is suitable for the preparation of composite films and multi-layer films of various materials. The highest vacuum degree of the vacuum system can reach 6.6×10 -5 Pa, the ultra-high vacuum effectively protects the quality of the film.

[0024] Material preparation: the sputtering target is 99.999% Cu and 99.99% Ru in purity, 75 mm in diameter, about 3 mm thick, and the substrate is single crystal Si (111). In order to improve the adhesion between the Cu(R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com