Progressive stoving neutralization reaction device and method

A reaction device and progressive technology, applied in the direction of using oxidation/reduction purification, using alkaline earth compound purification, etc., can solve the problems of insufficient neutralization reaction of sugarcane juice, low purification efficiency, short reaction time, etc., to reduce sulfur dioxide residue, The effect of improving product quality and sugar yield and reducing the color value of white sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

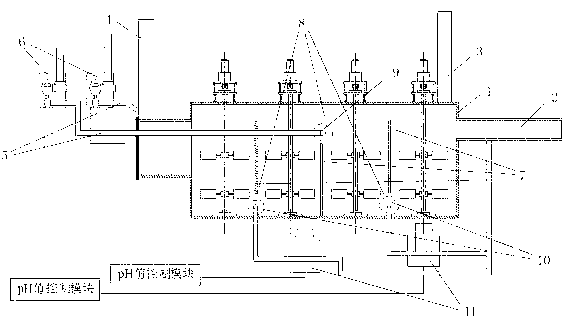

[0058] Such as figure 1 and figure 2 As shown, this embodiment includes a box body 1, a juice discharge port 2, a diffuser pipe 3, a sulfur smoker tail pipe 4, a lime milk adding pipe 5, an ash adding actuator 6, a partition 7, and a pH control device;

[0059] The box 1 is a connecting body of a plurality of cylindrical reaction layers, and the box 1 is divided into four reaction layers by a partition 7 in the horizontal direction; each reaction layer is connected in series in a straight line, and each reaction layer The partition 7 at the series connection is provided with through holes 8, and the through holes 8 on the partition 7 at the series connection of adjacent reaction layers are distributed in a staggered manner up and down; a lime milk adding pipe 5 is arranged in the reaction layer, and the lime milk The milk of lime adding pipe nozzle 9 of the milk adding pipe 5 is located at the through hole 8 at the top of the reaction layer, and the ashing actuator 6 is conn...

Embodiment 2

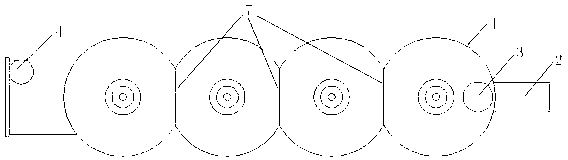

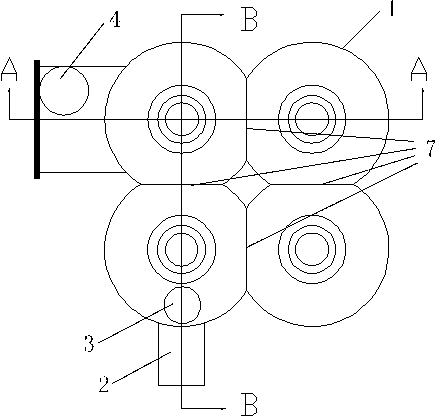

[0071] Such as Figure 3 ~ Figure 5 As shown, this embodiment includes a box body 1, a juice discharge port 2, a diffuser pipe 3, a sulfur smoker tail pipe 4, a lime milk adding pipe 5, an ash adding actuator 6, a partition 7, and a pH control device;

[0072] The box 1 is a connecting body of a plurality of cylindrical reaction layers, and the box 1 is divided into 4 reaction layers by a partition 7 in the horizontal direction; each reaction layer is connected in series with broken lines, except for the first In addition to the partition 7 between the first reaction layer and the last reaction layer, the partition 7 at the series connection of each reaction layer is provided with a through hole 8, and the through hole 8 on the partition 7 at the series connection of the adjacent reaction layers Distributed in an up and down staggered manner; a milk of lime adding pipe 5 is arranged in the reaction layer, and the mouth of the milk of lime adding pipe 5 of the milk of lime addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com