Preparation method for industrial nitric acid

A nitric acid, industrial technology, applied in the field of industrial nitric acid production, can solve the problems of inability to break bubbles, use restrictions, inability to fully dissolve nitrogen dioxide, etc., to achieve the effect of improving reaction efficiency and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

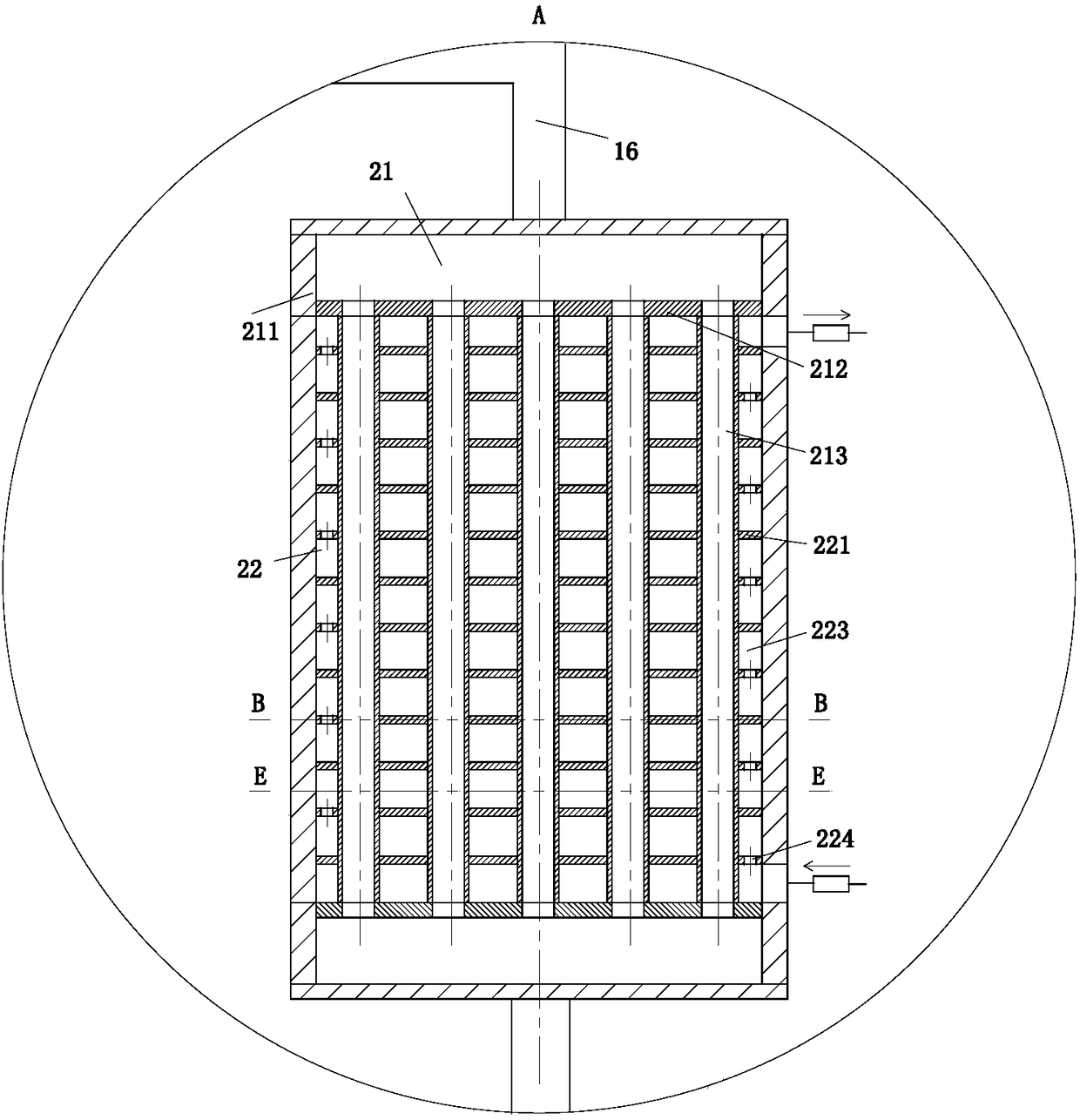

[0044] As an embodiment of the present invention, the cooling device 2 includes an infusion unit 21 and a cooling unit 22, and the infusion unit 21 includes a cooling cylinder 211, a No. 1 partition 212 and a No. 1 water pipe 213; two No. 1 partitions 212 is fixed seamlessly and symmetrically installed on the inner wall of the cooling cylinder 211; multiple No. 1 water pipes 213 are connected between the two No. 1 partitions 212; the cooling unit 22 is located between the two No. 1 partitions 212, The cooling unit 22 is used to cool the No. 1 water pipe 213; during operation, the distilled water in the absorption layer 18 enters the cooling cylinder 211 through the No. 1 liquid through hole 15 and the liquid supply pipe 16, and then enters through a plurality of No. 1 water pipes 213 In the cooling unit 22, a plurality of No. 1 water pipes 213 are used to divide the distilled water in the cooling device 2, which increases the cooling area of the No. 1 water pipe 213 of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com