Method for preparing mononuclear AgInS2 quantum dot

A technology of quantum dots and quantum dot solutions, which is applied in the hot injection method to prepare high-efficiency fluorescent AgInS2 quantum dots, which can solve the problems of low quantum yield of quantum dots, achieve strong repeatability, increase fluorescence quantum yield, and improve color temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In the first step, weigh 17.1mg (0.1mmol) AgNO 3 , 88.4 mg (0.4 mmol) InCl 3 , 169.5 mg (0.6 mmol) of oleic acid and 209.7 mg (1 mmol) of dodecyl mercaptan were placed in a 100 mL three-necked flask, and 8 mL of octadecene solvent was added.

[0038] In the second step, 26.2 mg (0.8 mmol) of sulfur powder was weighed, dissolved in 2 mL of oleylamine, and placed in a 50° C. water bath to fully dissolve the sulfur powder in oleylamine.

[0039] In the third step, under the conditions of magnetic stirring and argon protection, heat the precursor solution in the first step to 60°C for 30 minutes, then continue to heat up to 100-120°C, and after stabilizing for 2 minutes, inject the second step Dissolve S powder in oleylamine, and start timing.

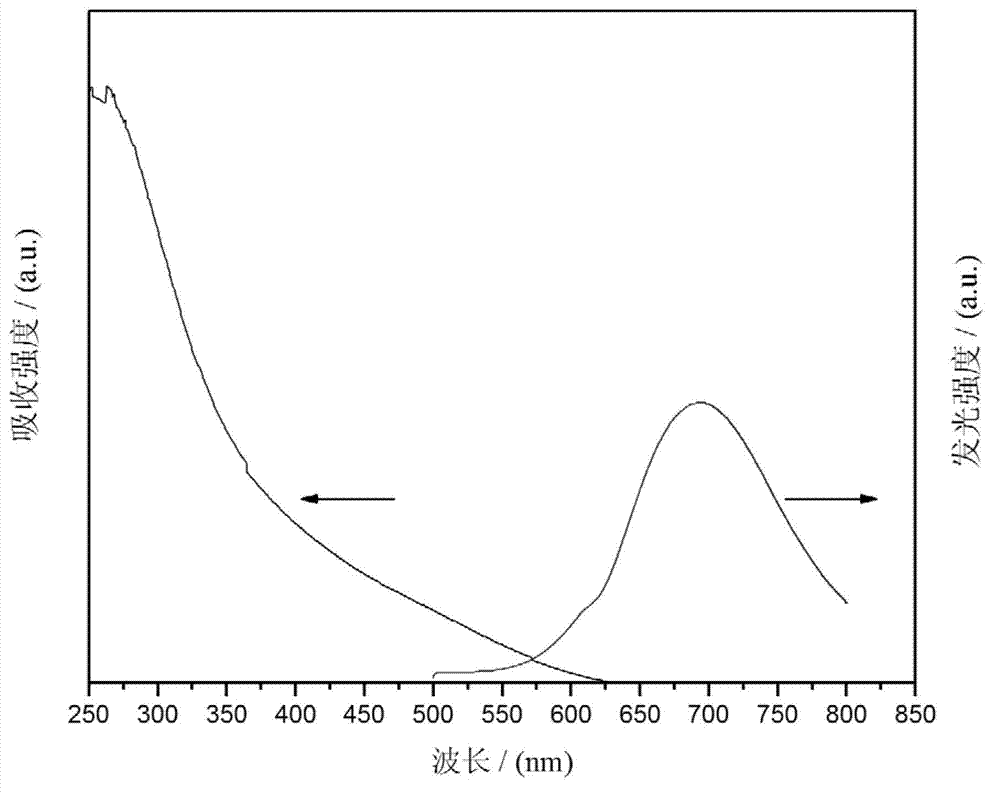

[0040] The fourth step is to take samples when the reaction time is 5min, 10min, 15min, 20min, 30min, 45min, 60min, 90min. Take 0.5mL reaction solution and dissolve in 0.5mL n-hexane to prepare AgInS 2 Quantum dot solution.

[...

Embodiment 2

[0047] In the first step, weigh 17.1mg (0.1mmol) AgNO 3 , 88.6mg (0.4mmol) InCl 3 , 169.8mg (0.6mmol) of oleic acid and 408.4mg (2mmol) of dodecyl mercaptan were placed in a 100mL three-necked flask, and 8mL of octadecene solvent was added.

[0048] In the second step, 25.8mg (0.8mmol) of sulfur powder was weighed, dissolved in 2mL of oleylamine, and placed in a 50°C water bath to fully dissolve the sulfur powder in oleylamine.

[0049] In the third step, under the conditions of magnetic stirring and argon protection, heat the precursor solution in the first step to 60°C for 30min, then continue to heat up to 110°C, and after stabilizing for 2min, inject the solution in the second step. Based on the S powder of oleylamine, start timing.

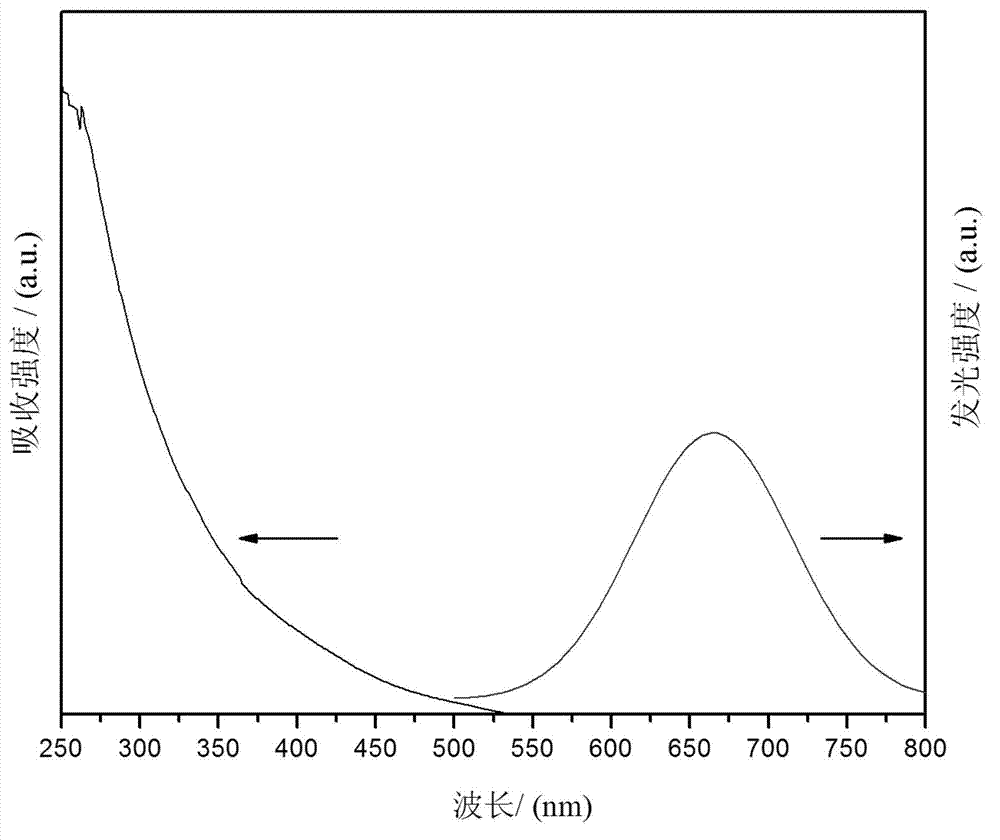

[0050] The fourth step is to take samples when the reaction time is 5min, 10min, 15min, 20min, 30min, 45min, 60min, 90min. Take 0.5mL reaction solution and dissolve in 0.5mL n-hexane to prepare AgInS 2 Quantum dot solution.

[0051] In t...

Embodiment 3

[0054] In the first step, weigh 16.8mg (0.1mmol) AgNO3 , 88.7mg (0.4mmol) InCl 3 , 170.8mg (0.6mmol) of oleic acid and 609.2mg (3mmol) of dodecyl mercaptan were placed in a 100mL three-necked flask, and 8mL of octadecene solvent was added.

[0055] In the second step, 26.1mg (0.8mmol) of sulfur powder was weighed, dissolved in 2mL of oleylamine, and placed in a 50°C water bath to fully dissolve the sulfur powder in oleylamine.

[0056] In the third step, under the conditions of magnetic stirring and argon protection, heat the precursor solution in the first step to 60°C for 30min, then continue to heat up to 110°C, and after stabilizing for 2min, inject the solution in the second step. Based on the S powder of oleylamine, start timing.

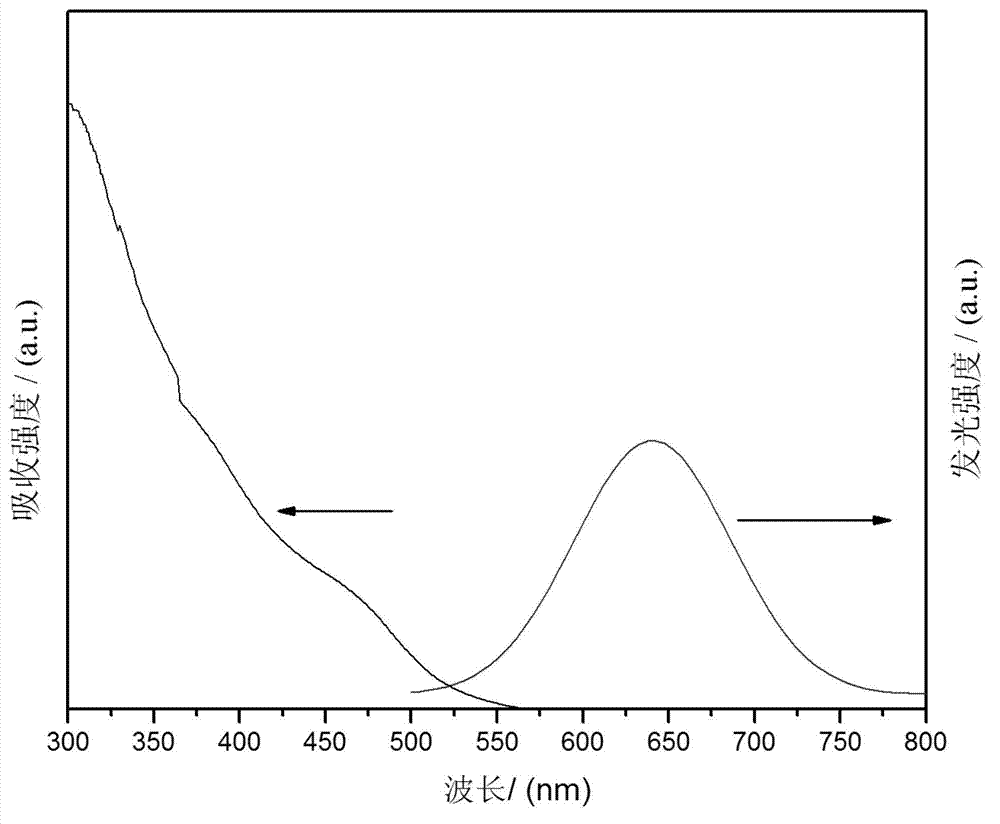

[0057] The fourth step is to take samples when the reaction time is 5min, 10min, 15min, 20min, 30min, 45min, 60min, 90min. Take 0.5mL reaction solution and dissolve in 0.5mL n-hexane to prepare AgInS 2 Quantum dot solution.

[0058] In the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com