Graphene-ceramic composite material and preparation method thereof

A ceramic composite material and composite material technology are applied in the field of graphene-ceramic composite material and its preparation, which can solve the problems of poor thermal stability of zirconium dioxide, underdeveloped pores, small specific surface, etc. Excellent ablation performance, increasing the effect of three-phase interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of graphene-ceramic composite material of the present invention, comprises the steps:

[0033] 1) Preparation of graphene oxide-metal oxide composites:

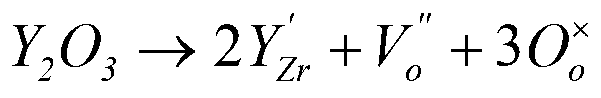

[0034] The parts by weight are 40-99.85 parts of cerium salt or zirconium salt (cerium chloride, zirconium chloride, cerium nitrate, zirconium nitrate, cerium sulfate, zirconium sulfate, cerium carbonate, zirconium carbonate, cerium acetate, zirconium acetate, cerium oxalate , zirconium oxalate), 0.03-40 parts of additives (the metal salt of additives is chloride, nitrate, sulfate, carbonate, acetate, oxalate of yttrium Y, scandium Sc, samarium Sm or gadolinium Gd The additive metal oxide is the oxide of yttrium Y, scandium Sc, samarium Sm or gadolinium Gd) and graphene oxide with 0.1-30 parts by weight is dissolved in ethanol, and the raw materials are ultrasonically dispersed, and the temperature is Co-decompose into metal oxides at 600-1200°C to obtain composite materials;

[0035] A. First ...

Embodiment 1

[0047] A. First compound cerium salt (or zirconium salt) with additives, and then compound with graphene oxide:

[0048] The method of thermal decomposition of nitrate is adopted, and samarium nitrate is used as an auxiliary agent in this embodiment. Weigh 400mg Ce(NO 3 ) 3 ·6H 2 O and 100mg Sm(NO 3 ) 3 ·6H 2 O, add 100ml of absolute ethanol, ultrasonically disperse for 2h, ball mill at 450r / min for 3.5h, decompose at 700°C to obtain CeO 2 and Sm 2 o 3 mixture. The obtained mixture is fully mixed with 50mg graphene oxide to obtain graphene oxide-CeO 2 Base Composite 237mg. Add 150mg of organic adhesive (PVB and n-butanol solvent with a weight ratio of 1:1) to the powder, mix and grind thoroughly. Among the raw materials, the parts by weight of graphene oxide, cerium nitrate, samarium nitrate and organic adhesive are 10, 80, 20 and 30 parts respectively.

[0049] After drying, use dry pressing method to press under 10MPa, place in 150ml / min H 2 / He mixed gas vacuum...

Embodiment 2

[0054] B. First compound cerium salt (or zirconium salt) with graphene oxide, and then compound with additives:

[0055] The method of thermal decomposition of nitrate is adopted, and gadolinium nitrate is used as an auxiliary agent in this embodiment. Weigh 300mg Ce(NO 3 ) 3 ·6H 2 O and 75mg graphene oxide, add 100ml absolute ethanol, ultrasonically disperse for 2h, ball mill at 450r / min for 3.5h, decompose at 1200°C to obtain CeO 2 and graphene oxide mixture. The resulting mixture was then mixed with 200mg Gd(NO 3 ) 3 .6H 2 O was mixed thoroughly, after adding 100ml of absolute ethanol, ultrasonically dispersed for 2h and ball milled at a speed of 450r / min for 3.5h, decomposed at 1200°C to obtain graphene oxide-CeO 2 Base Composite 264mg. Add 225mg of organic adhesive (PVB and n-butanol solvent with a weight ratio of 0.1:1) to the powder, mix and grind thoroughly. Among the raw materials, the parts by weight of graphene oxide, cerium nitrate, gadolinium nitrate and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com