Integrated type energy-saving and environment-friendly hydraulic servo system

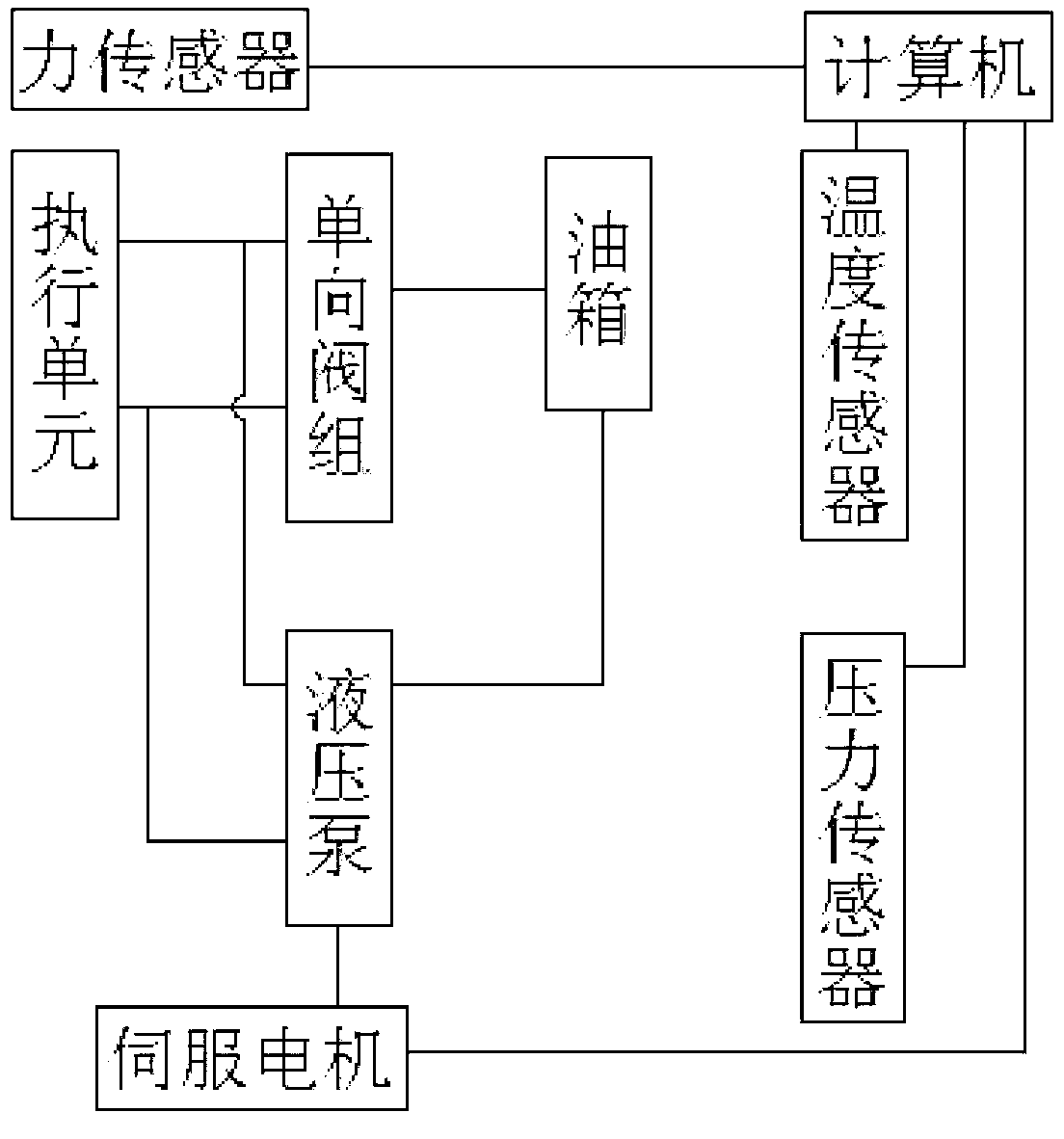

A hydraulic servo system, energy saving and environmental protection technology, applied in fluid pressure actuation system components, presses, fluid pressure actuation devices, etc., can solve the problems of increased oil leakage and failure, energy consumption, and large space occupation , to achieve the effect of improving work efficiency, reducing loss along the way, and occupying less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

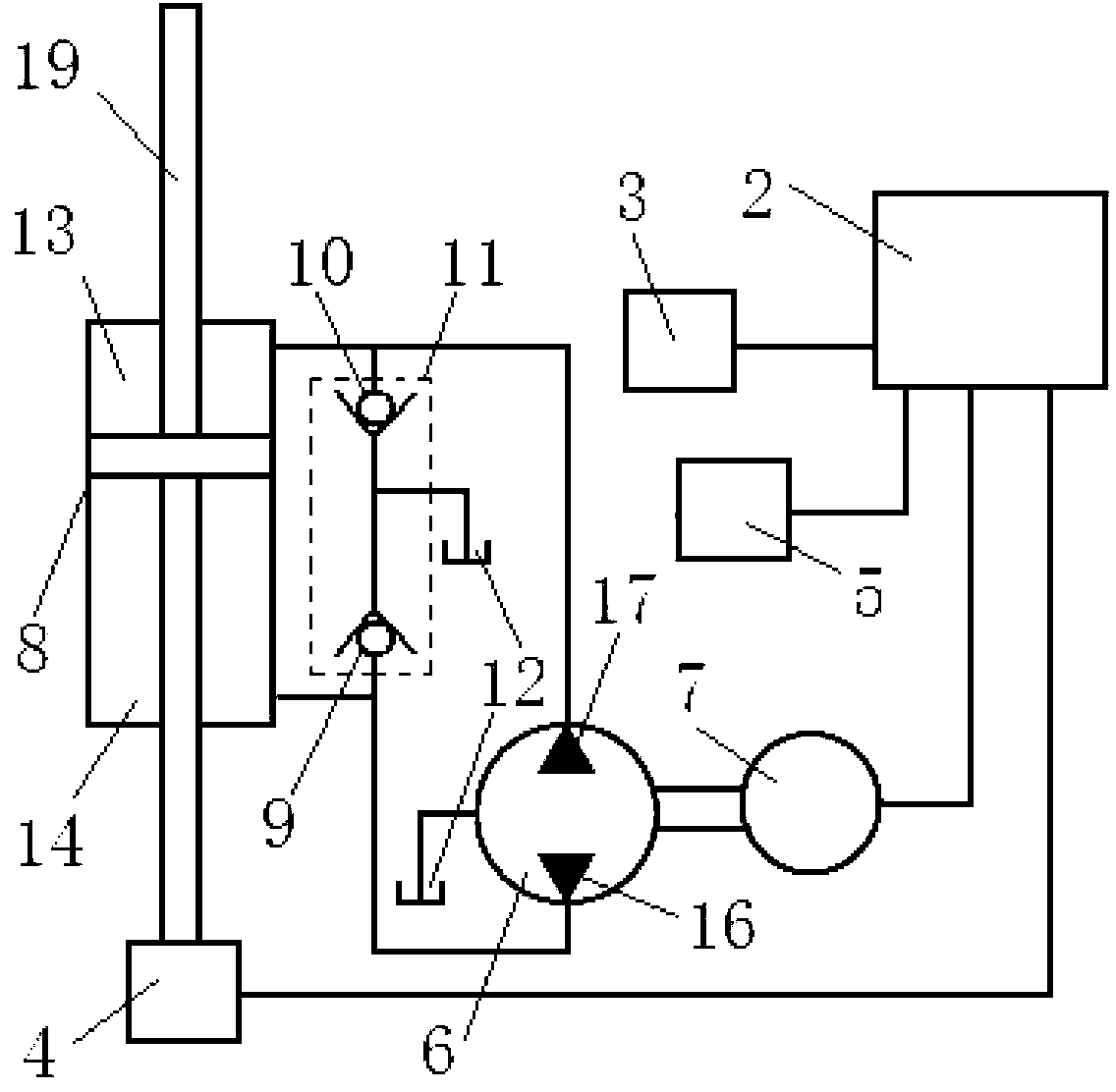

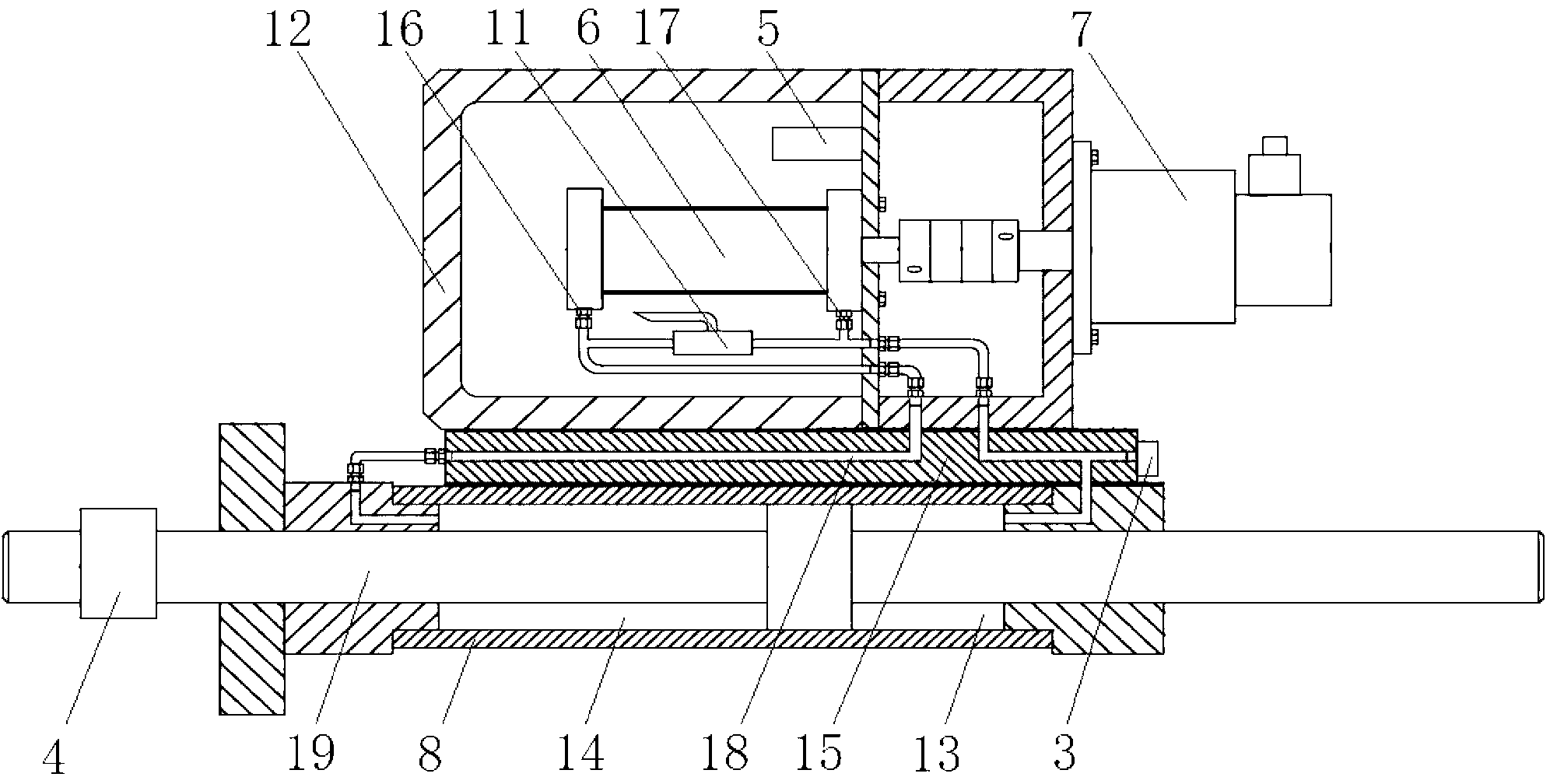

[0030] The invention is applied to a powder alloy press forming hydraulic press.

[0031] In this embodiment, the hydraulic pump 6 of the power output control part adopts the model Taisheng SNBY16 / 1.6 two-way gear oil pump, the servo motor 7 adopts the model of Beijing Senchuang 130MB series AC servo motor, and the pressure sensor 3 adopts the model of Beijing Zhengkai Instrument Co., Ltd. The company's MCY-B1 stainless steel pressure sensor (range 0 ~ 20Mpa), the force sensor 4 adopts the MCL-S2 tension pressure sensor (range 0 ~ 100kN) of Beijing Zhengkai Instrument Co., Ltd., and the temperature sensor 5 adopts the model It is a TE-80 digital display temperature sensor (range -50-200°C) of BANNA Company in the United States.

[0032] Make the powder alloy pressing and forming hydraulic machine energized, the computer 2 of the present invention starts, and it can be seen by the computer 2 that the rotating speed of the servo motor 7 is zero at this time, the initial values ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com