A kind of brazing layer pre-deposition method

A technology of pre-deposition and brazing layer, applied in the direction of welding equipment, electrical components, circuits, etc., can solve the problems of poor uniformity of solder paste or solder melting degree, poor welding quality consistency, low positioning accuracy, etc., and achieve uniform melting degree Good performance, reduced processing workload, and improved welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

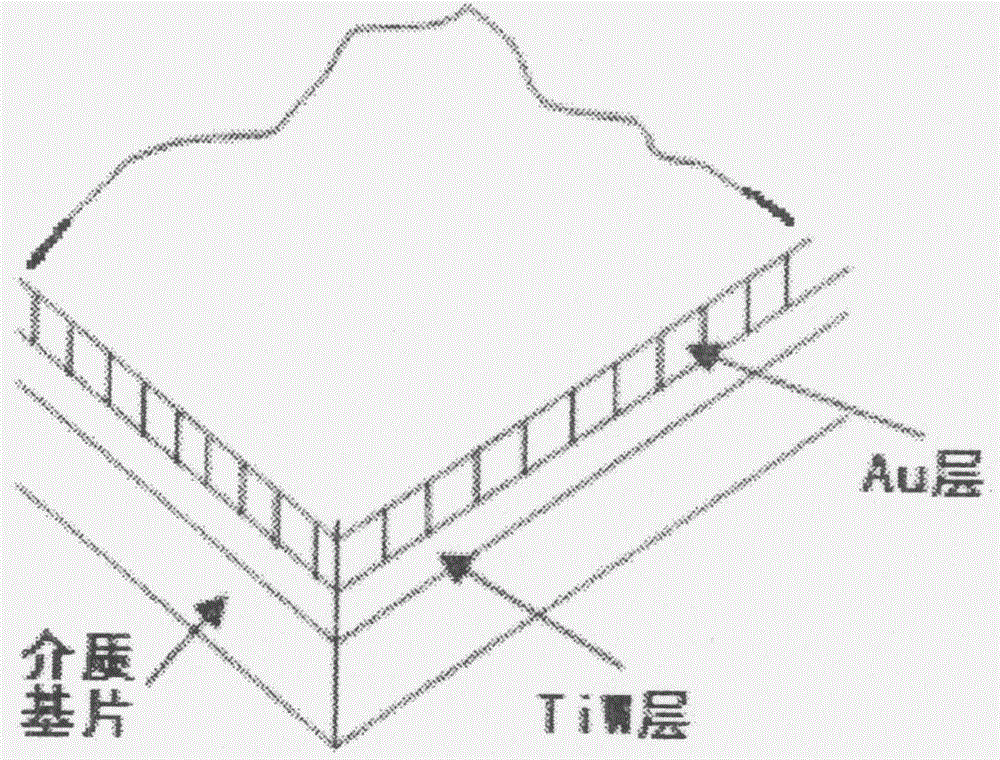

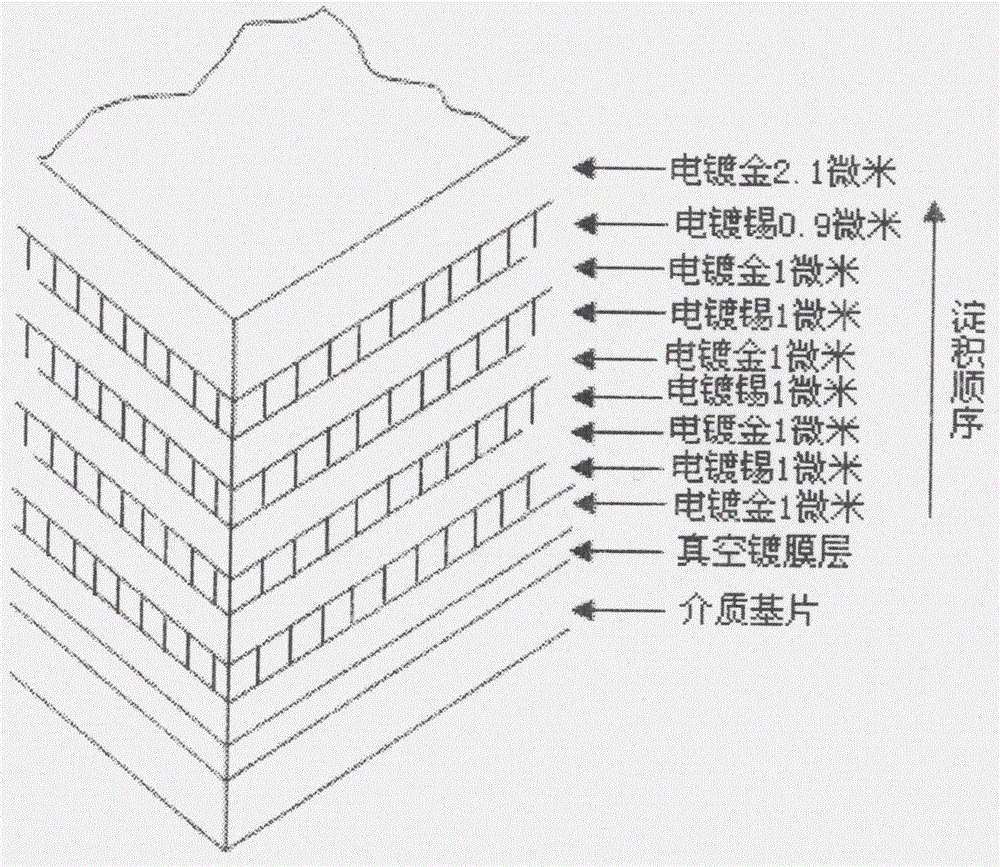

[0030] Such as Figure 1 to Figure 2 As shown, the technical scheme of the present invention takes the electroplating pre-deposition of gold-tin eutectic solder commonly used in hybrid integrated circuits as an example, and the scheme adopts the scheme of electroplating multiple layers of gold and tin layers, so that the two components of gold and tin The uniformity of the alloy composition is as close as possible to the uniformity of the alloy composition. The implementation process in the scheme is as follows:

[0031] Vacuum sputtering coating seed layer:

[0032] In this scheme, the deposition of the adhesion layer and the electroplating seed layer on the welding surface of the hybrid integrated circuit adopts the method of magnetron sputtering, and successively deposits the adhesion layer (such as TiW layer) and the electroplating seed layer on the dielectric substrate of the hybrid integrated circuit respectively. layer (eg Au layer), such as figure 1 shown;

[0033] ...

Embodiment 2

[0036] On the basis of the above embodiments, further, a brazing layer pre-deposition method of the present invention, which includes the following steps:

[0037] A: Vacuum sputtering coating seed layer;

[0038] B: Each layer is deposited by alternate electroplating of gold and tin layers in sequence.

[0039] Preferably, in the step A, the adhesion layer and the electroplating seed layer are sequentially deposited on the circuit dielectric substrate by using the method of magnetron sputtering, which is a solution that can be realized in the prior art.

[0040] Preferably, the circuit dielectric substrate is a hybrid integrated circuit dielectric substrate.

[0041] Preferably, in the step B, the density of gold is 19.3g / cm 3 ;The density of tin is 7.31g / cm 3 , here, the density of gold can also be 20.3g / cm 3 ;The density of tin is 8.31g / cm 3 .

[0042] Preferably, in the step B, the weight ratio of gold and tin is 80.4:19.6, here the weight ratio can also be 80.7:19.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com