Golden camellia flower tea processing method

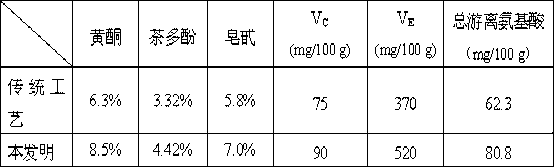

A processing method and technology for golden camellia tea, applied in the direction of pre-extraction tea treatment, etc., can solve problems such as difficulty in completely preserving the shape of flowers, poor quality, etc., and achieve the effects of good health care and medicinal effects, stable product quality, and fragrant smell.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The processing method of golden camellia flower tea of the present invention comprises the steps:

[0023] (1) Fresh flowers quick-freezing and shaping: put 1kg of fresh flowers of Camellia japonica into the cold storage at -15°C for 1 hour, and freeze the flowers into a solid shape;

[0024] (2) Vacuum freeze-drying: Put the finalized fresh flowers of Camellia japonica into a vacuum freeze dryer for drying, the freezing temperature is -40°C to -50°C, the vacuum degree is 8~15Pa, and the drying time is 10 hours until the flower tea contains Water volume 20%~25%;

[0025] (3) Microwave de-enzyming: return the Camellia japonica flowers after vacuum freeze-drying to normal temperature, and then perform microwave de-enzyming treatment. The power of the microwave de-enzyming machine is 24~26KW, the de-enzyming temperature is 90°C, and the time is 1.5 minutes;

[0026] (4) Vacuum drying: put the flowers after microwave killing into a vacuum dryer for drying, the drying tem...

Embodiment 2

[0032] The processing method of golden camellia flower tea of the present invention comprises the steps:

[0033] (1) Fresh flowers quick-freezing and setting: Put 1kg of Camellia japonica fresh flowers within 12 hours after picking into the cold storage, freeze them at -10°C for 2 hours, and freeze the flowers into a solid shape;

[0034] (2) Vacuum freeze-drying: Put the finalized fresh flowers of Camellia japonica into a vacuum freeze dryer for drying, the freezing temperature is -45°C to -50°C, the vacuum degree is 10~15Pa, and the drying time is 11 hours until the flower tea contains Water volume 20%~25%;

[0035] (3) Microwave deenzyming: return the Camellia japonica flowers after vacuum freeze-drying to normal temperature, and then perform microwave deenzyming treatment. The power of the microwave deenzyming machine is 28~30KW, the deenzyming temperature is 100°C, and the time is 1min;

[0036] (4) Vacuum drying: put the flowers after microwave killing into a vacuum ...

Embodiment 3

[0040] The processing method of golden camellia flower tea of the present invention comprises the steps:

[0041] (1) Fresh flowers quick-freezing and setting: put 1kg of Camellia japonica fresh flowers within 12 hours after picking into the cold storage, freeze them at -12°C for 1.5 hours, and freeze the flowers into a solid shape;

[0042] (2) Vacuum freeze-drying: Put the shaped fresh flowers of Camellia japonica into a vacuum freeze dryer for drying, the freezing temperature is -45°C to -50°C, the vacuum degree is 8~10Pa, and the drying time is 12 hours until the flower tea contains Water volume 20%~25%;

[0043] (3) Microwave deenzyming: return the Camellia japonica flowers after vacuum freeze-drying to normal temperature, and then perform microwave deenzyming treatment. The power of the microwave deenzyming machine is 25~27KW, the deenzyming temperature is 80°C, and the time is 2 minutes;

[0044] (4) Vacuum drying: Put the flowers after microwave killing into a vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com