Detecting device and method

A detection device and detection method technology, applied in the field of detection, can solve the problems of low recognition rate of liquid crystal panels, prone to false detection, low detection efficiency, etc., so as to improve the defect recognition rate and detection efficiency, improve work efficiency, and improve production automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

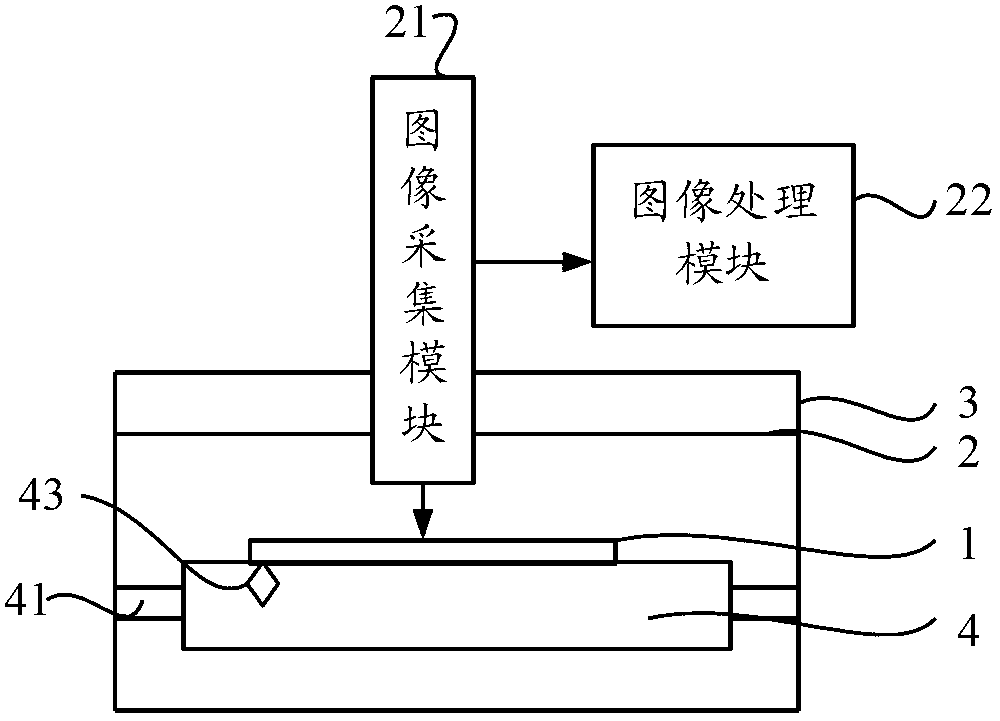

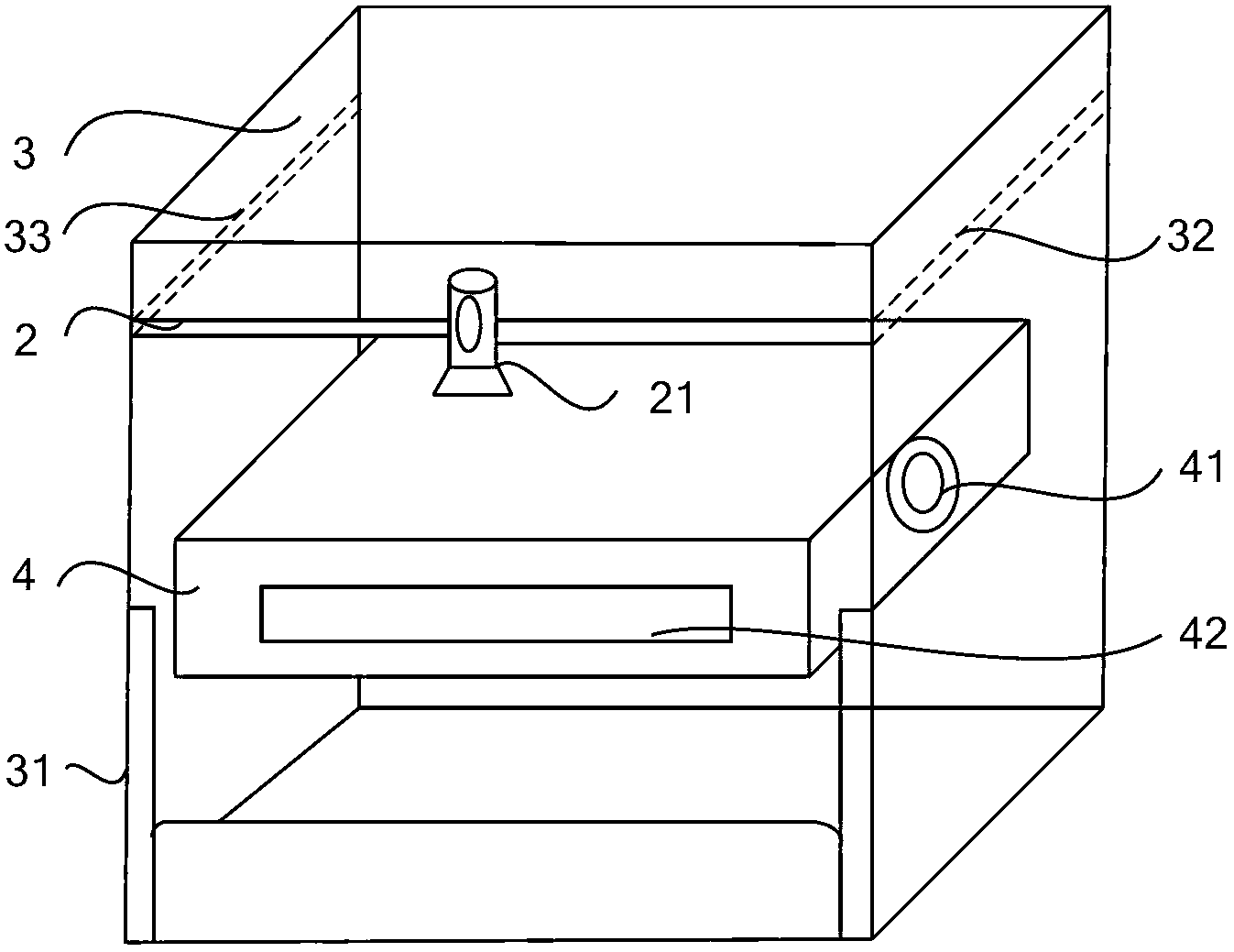

[0067] The principle schematic diagram of the detection device provided by the present invention is as follows: figure 1 As shown, the detection device includes:

[0068] An image acquisition module 21 for collecting the image information of the liquid crystal panel 1 to be tested;

[0069] The image processing module 22 is signal-connected with the image acquisition module 21. The image processing module 22 compares the received image information with the defect database to determine the defect level of the liquid crystal panel 1 to be tested.

[0070] Machine vision defect detection is based on the comparison and matching of the defect library to determine whether the defect exceeds the requirements. The defect detection needs to build the defect library of the inspected item, and quickly compare the physical object with the defect library to replace the human eye to make a qualified judgment. Defect detection requires as large an optical field of view as possible to be abl...

Embodiment 2

[0095] The present invention also provides a detection method, the flow chart of the detection method is as follows Figure 5 shown, including:

[0096] Step S501: loading the liquid crystal panel to be tested;

[0097] Step S502: the image acquisition module collects the image information of the liquid crystal panel to be tested;

[0098] Step S503: The image processing module compares the received image information with the defect database to determine the defect level of the liquid crystal panel to be tested.

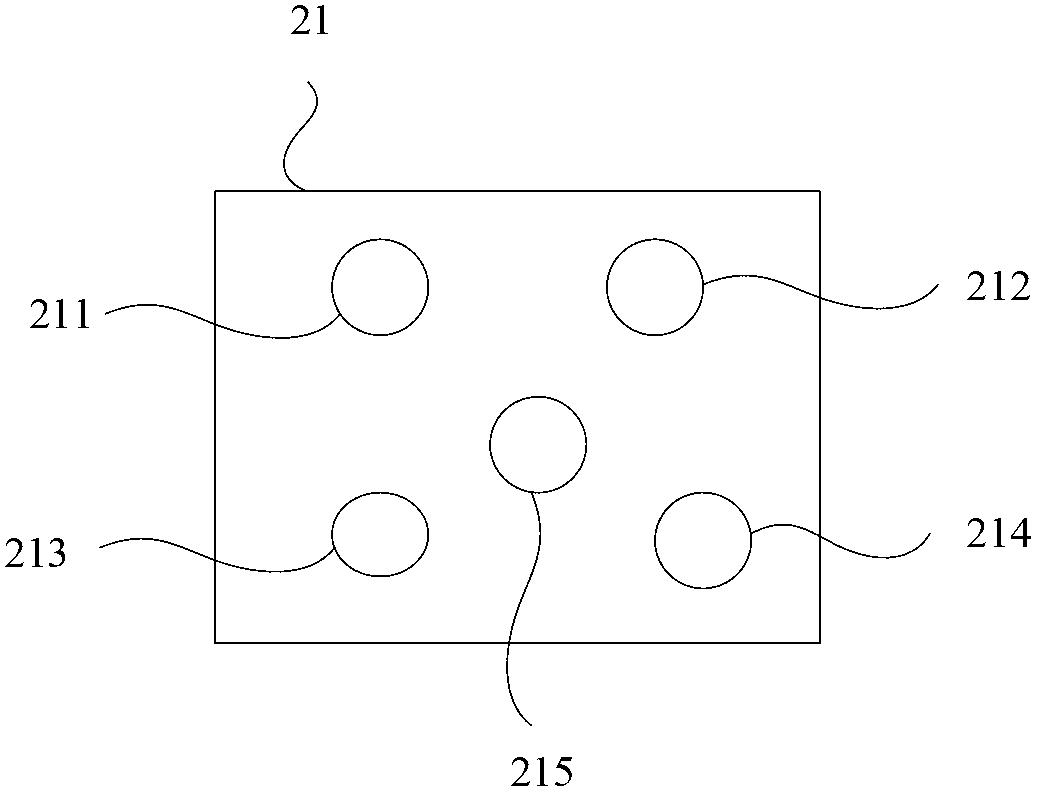

[0099] Preferably, the image acquisition module includes: a first camera tube, a second camera tube, a third camera tube, a fourth camera tube, and a fifth camera tube. Step S502: the image acquisition module collects the image information of the liquid crystal panel to be tested, which specifically includes :

[0100] Use the first camera tube to collect bad image information caused by foreign matter and / or air bubbles of the liquid crystal panel to be tested;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com