Flame-retardant PVC (polyvinyl chloride) composite material and preparation method thereof

The technology of composite material and degree of polymerization is applied in the field of halloysite synergistic zinc hydroxystannate flame retardant PVC composite material and its preparation field, which can solve the problems of large amount of smoke and poor flame retardant performance, and achieves good dispersibility, The effect of reducing cost, improving mechanical properties and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

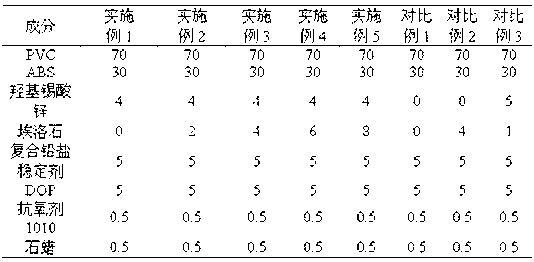

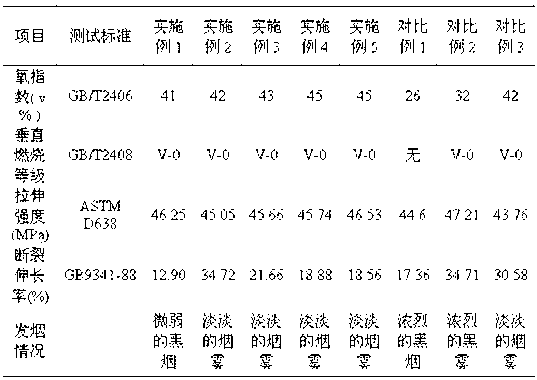

Embodiment 1-5

[0027] The preparation of flame-retardant PVC composite material, the preparation steps are as follows:

[0028] Mix the components of the blended modified flame-retardant PVC composite material and then banbury on the internal mixer. The temperature of the internal mixer is 175°C to obtain a block material, and then press it on a flat vulcanizer at 185°C to form a flat plate. The final sample preparation test; the formula is as follows, see Table 1, and the properties obtained are shown in Table 2.

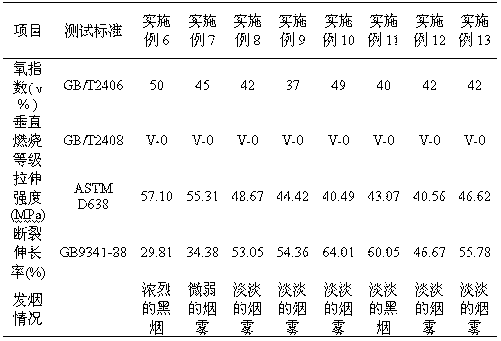

Embodiment 6-13

[0044] The preparation steps of flame retardant PVC composite materials of different systems are as follows:

[0045] Mix the components of the blended modified PVC composite material and then banbury on the internal mixer. The temperature of the internal mixer is 175°C to obtain a block material, and then press it on a flat vulcanizer at 185°C to form a flat plate, and finally make sample test. The formula is as follows, see Table 3, and the properties obtained are shown in Table 4.

[0046] Table 3 The distribution ratio of various components of flame-retardant PVC composite materials in different systems (fixed PVC and ABS weight sum is 100 parts)

[0047]

[0048] Table 4 Properties of flame retardant PVC composites in different systems

[0049]

[0050] From the data in Table 4, it can be seen that except for the composite material containing 90 phr of PVC, which has a large amount of smoke, the rest of the flame retardant and smoke suppression effects have good e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com