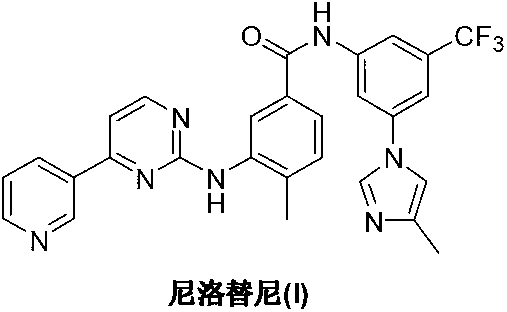

Preparation method of nilotinib

A nilotinib and condensation reaction technology, which is applied in the field of nilotinib preparation, can solve the problems of rare raw materials, high cost, and long steps, and achieve the effects of controllable production, improved product quality, and promoted development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

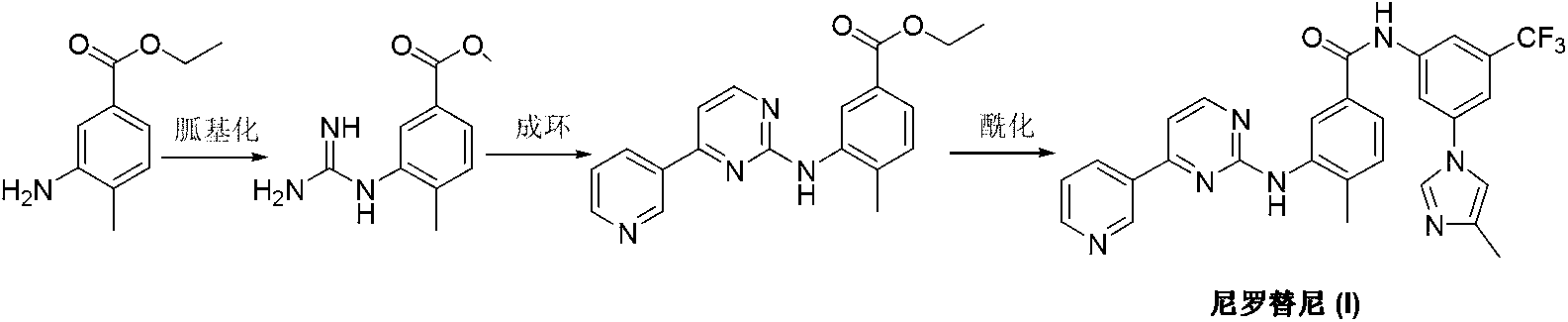

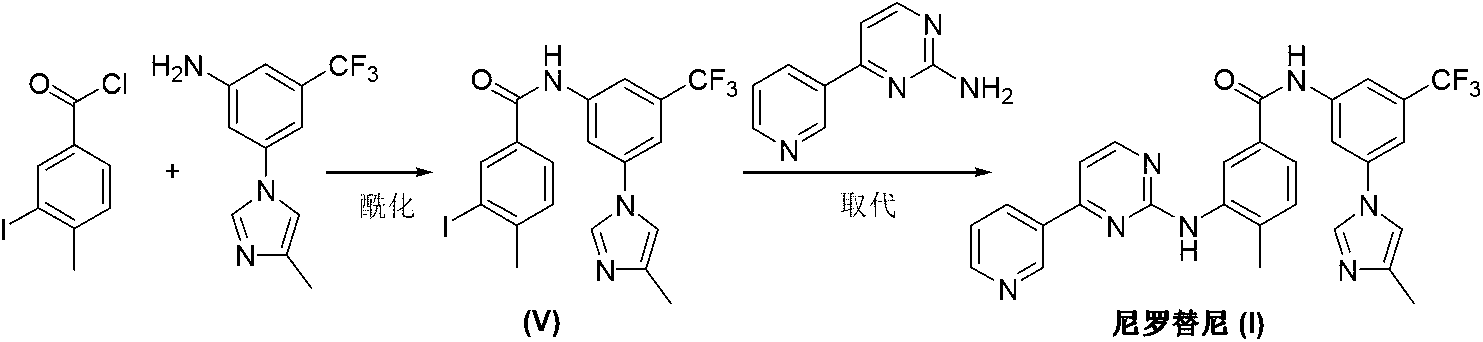

Method used

Image

Examples

Embodiment 1

[0025] Under nitrogen protection, 4-(3-pyridyl)-2-pyrimidinone (II) (1.73g, 10mmol), benzotriazol-1-yloxytris(dimethylamino) Phosphonium hexafluorophosphate (BOP) (6.63 g, 15 mmol) and acetonitrile 50 mL. Under stirring, 1,8-diazabicyclo[5.4.0]-undec-7-ene (DBU) (2.28 g, 15 mmol) was added dropwise, and the reaction was carried out at room temperature for 12 hours. The temperature was raised to 70° C., methyl 3-amino-4-methylbenzoate (III) (2.15 g, 13 mmol) and potassium tert-butoxide (1.65 g, 15 mmol) were added, and the reaction was continued for 12 hours. About half of the volume of the solvent was distilled off under reduced pressure, 30 mL of 2M sodium hydroxide was added, and the mixture was reacted at 80°C for 6 hours. Extracted 3 times with 120 mL of ethyl acetate, separated the organic phase, dried and concentrated under reduced pressure. The residue was dissolved in 100 mL THF, 5-(4-methyl-1H-imidazol-1-yl)-3-trifluoromethylaniline (IV) (2.89 g, 12 mmol) and 1,8-di...

Embodiment 2

[0027] Under nitrogen protection, 4-(3-pyridyl)-2-pyrimidinone (II) (1.73g, 10mmol), benzotriazol-1-yloxytris(dimethylamino) Phosphonium hexafluorophosphate (BOP) (6.63 g, 15 mmol) and acetonitrile 50 mL. Under stirring, 1,5-diazabicyclo[4.3.0]-non-5-ene (DBN) (1.86 g, 15 mmol) was added dropwise, and the reaction was carried out at room temperature for 12 hours. The temperature was raised to 70° C., methyl 3-amino-4-methylbenzoate (III) (2.15 g, 13 mmol) and potassium tert-butoxide (1.65 g, 15 mmol) were added, and the reaction was continued for 12 hours. About half of the volume of the solvent was distilled off under reduced pressure, 30 mL of 2M sodium hydroxide was added, and the mixture was reacted at 80°C for 6 hours. Extracted 3 times with 120 mL of ethyl acetate, separated the organic phase, dried and concentrated under reduced pressure. The residue was dissolved in 100 mL THF, and 5-(4-methyl-1H-imidazol-1-yl)-3-trifluoromethylaniline (IV) (2.89 g, 12 mmol) and 1,5-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com