Method for preparing activated carbon

A technology for preparing activated carbon and activated carbon, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problem of low wear resistance of activated carbon, and achieve the effect of high wear resistance and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

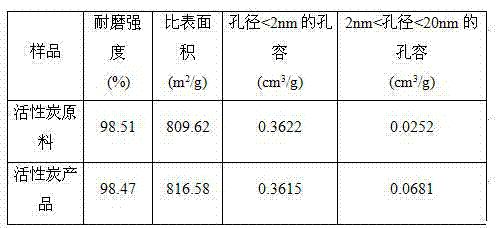

Embodiment 1

[0023] Weigh 8.8 g of soluble starch (reagent of analytical grade, Tianjin Guangcheng Chemical Reagent Co., Ltd.) and 3.4 g of polyvinyl alcohol (average molecular weight of 2000, Shanghai Kaidu Industrial Development Co., Ltd.), add them to a 250mL conical flask, and add 60g Dissolve in deionized water for 2 hours at 100°C; weigh 20g of activated carbon raw material (coconut shell activated carbon, particle size: 20-44 mesh, Shijiazhuang Hongsen Activated Carbon Co., Ltd.), add it to a triangular flask, shake well, and place at 50°C, Immerse in a shaker at 120 rpm for 6.5 hours, and then dry at 150°C for 29 hours; the dried sample was placed in a microwave high-temperature sintering furnace (HAMiLab-V3000 microwave high-temperature sintering furnace, Nanjing Xianou Instrument Manufacturing Co., Ltd.) Carbonization at 680°C for 3 hours in a nitrogen atmosphere, and then cooling in a nitrogen atmosphere to obtain 21.76g of the product, the wear resistance, specific surface area ...

Embodiment 2

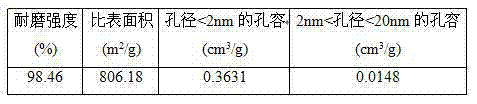

[0025] In the process of embodiment 2 (comparative example), polyvinyl alcohol is not added, and the pore volume (0.0148 cm) of the prepared activated carbon is between 2nm3 / g) less than the pore volume (0.0681 cm) of the activity prepared in Example 1 between 2nm3 / g).

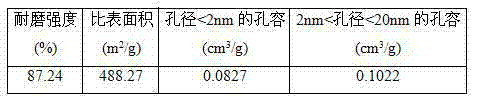

Embodiment 3

[0026] In the process of embodiment 3 (comparative example), no active carbon raw material is added, and the process prepares active carbon for the polymer blending carbonization method, and the wear resistance (87.24%) of the prepared active carbon is less than the active carbon wear resistance prepared by embodiment 1 (98.47%) %).

[0027] Embodiment 2 (comparative example)

[0028] Weigh 8.8g of soluble starch (reagent of analytical grade, Tianjin Guangcheng Chemical Reagent Co., Ltd.), add it to a 250mL conical flask, add 60g of deionized water, and dissolve for 2 hours at 100°C; weigh 20g of activated carbon raw material (coconut shell Activated carbon, particle size: 20-44 mesh, Shijiazhuang Hongsen Activated Carbon Co., Ltd.), added to the conical flask, shaken, immersed in a shaker at 50°C and 120 rpm for 6.5 hours, and then dried at 150°C for 29 hours The dried sample was carbonized at 680° C. for 3 hours under a nitrogen atmosphere in a microwave high-temperature si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com