Cooling unit for traction system

A cooling unit and traction system technology, applied to locomotives, etc., can solve the problems of uncompact structure, large overall volume, and heavy overall weight, and achieve the effect of compact structure, small maintenance workload, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

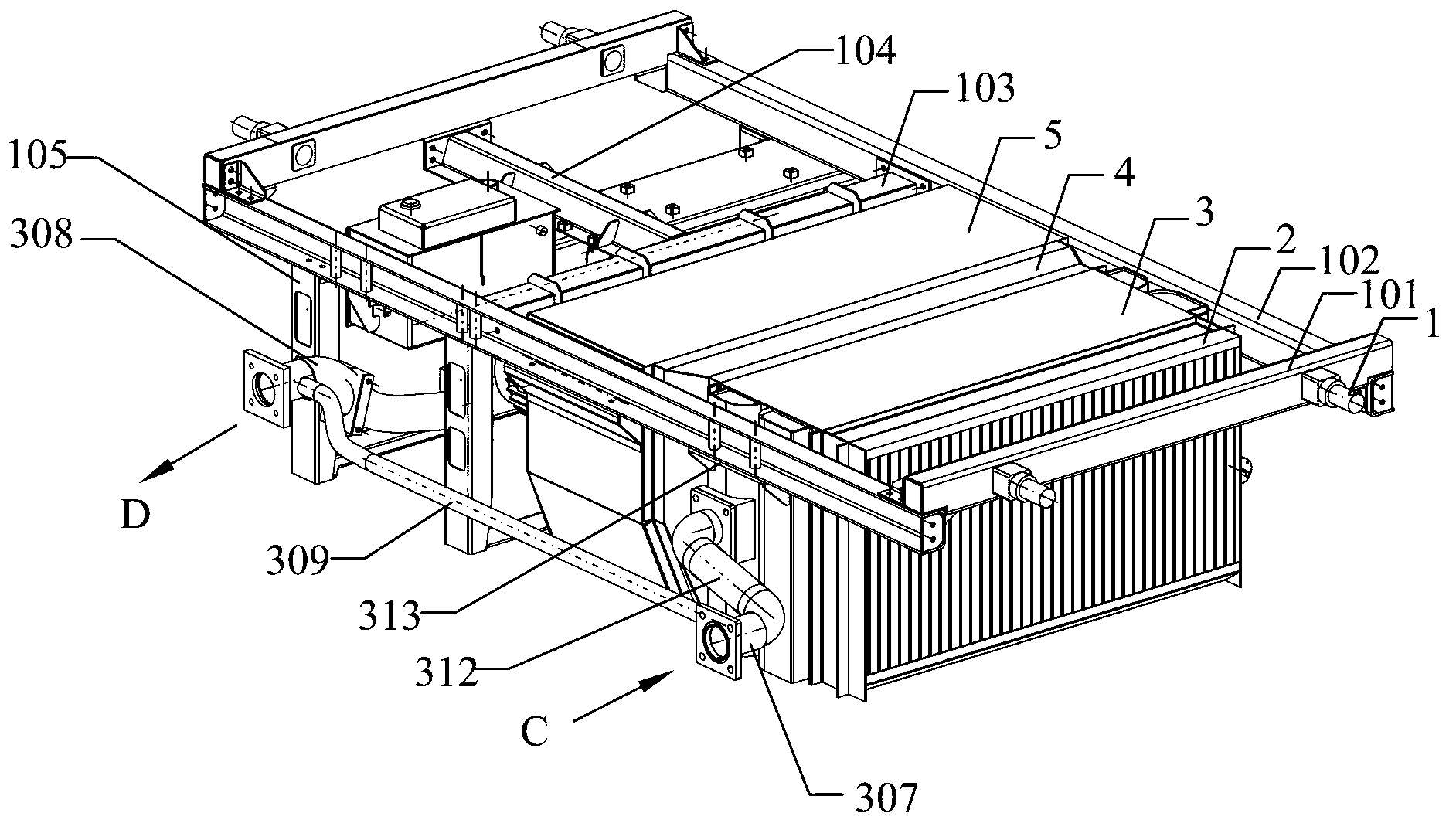

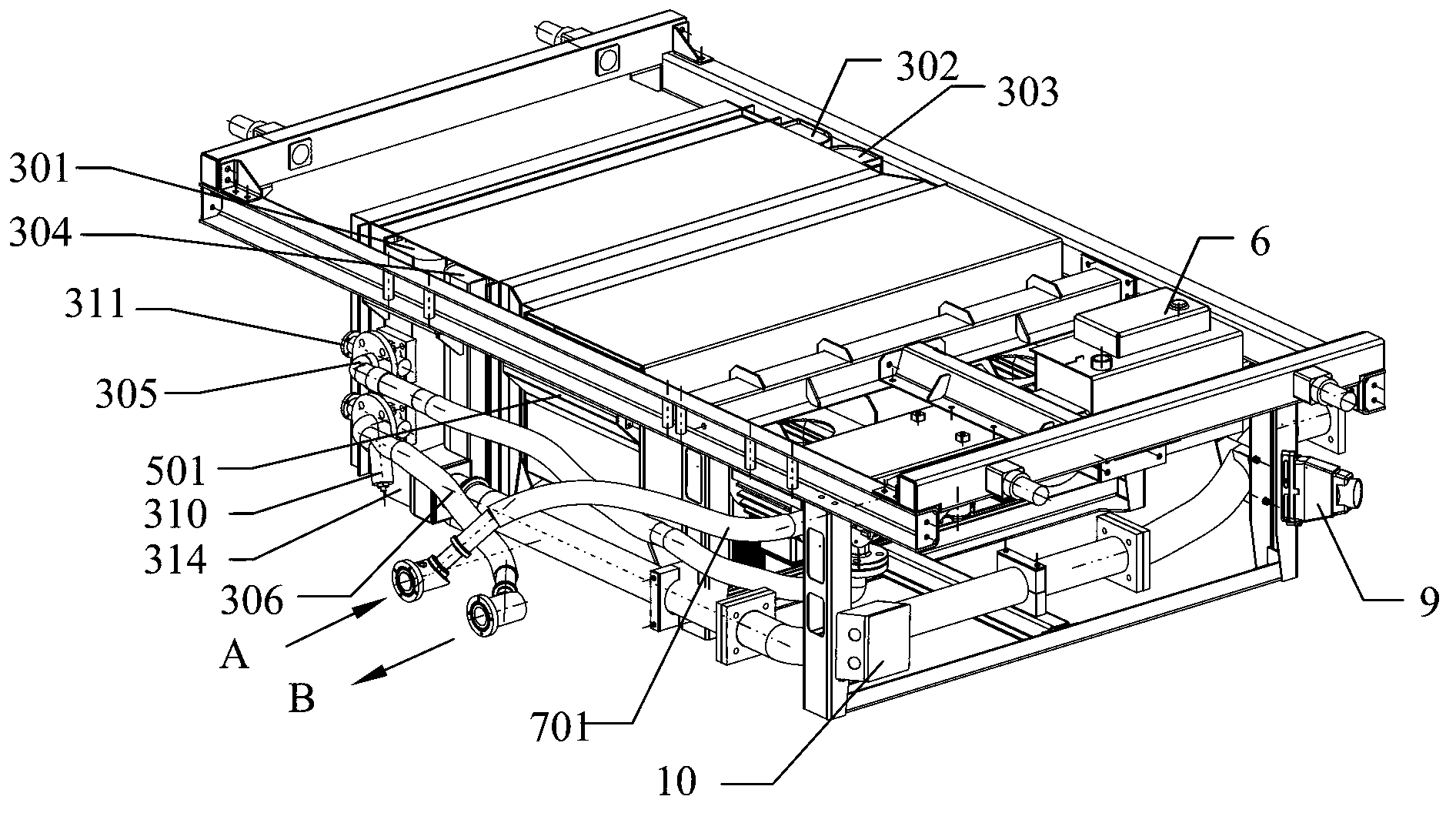

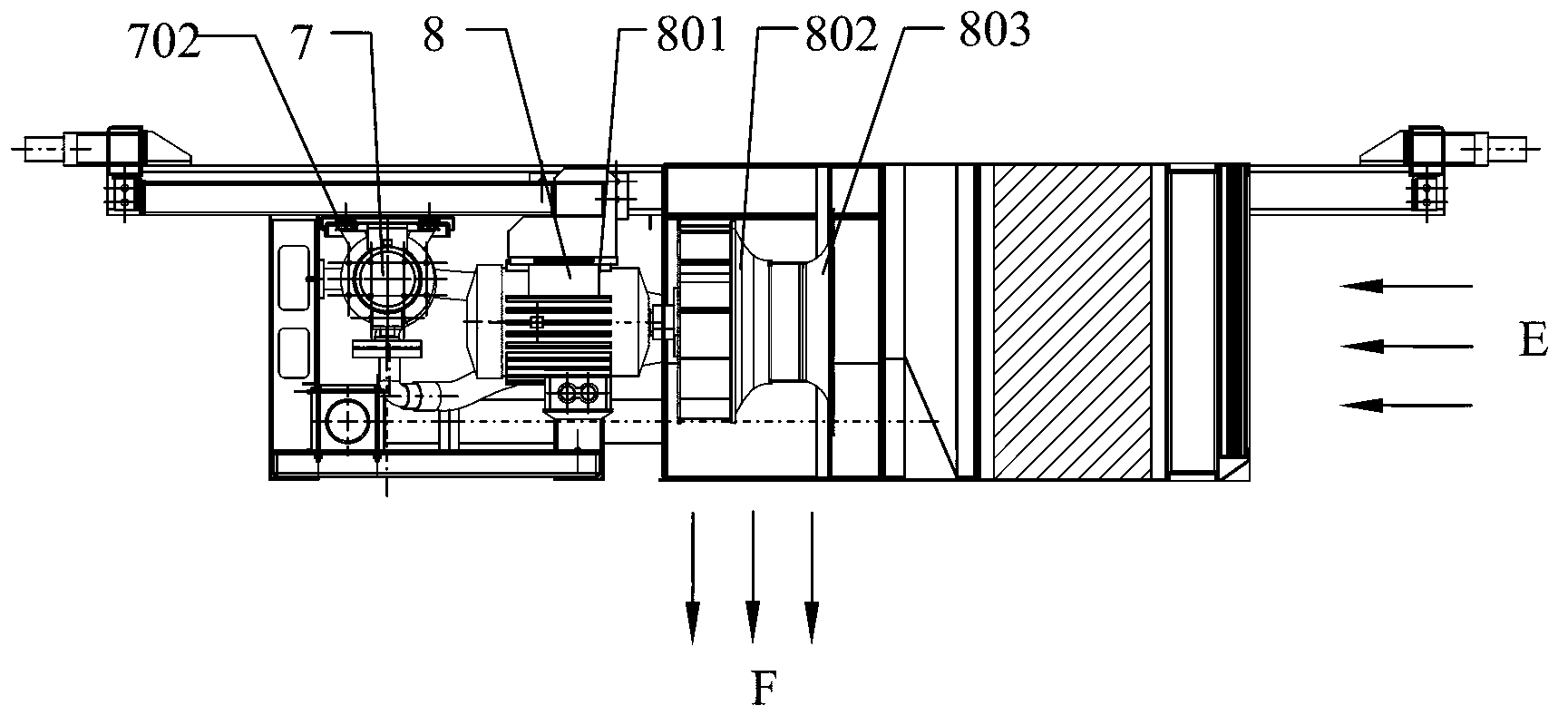

[0036] Such as Figure 1 to Figure 3 As shown, a cooling unit for a traction system includes a load-bearing support frame 1, an air filter device 2, a radiator 3, an air guide tube 4, a fan box 5, an expansion tank 6, a water pump 7, a fan unit 8 and fixed on the The electrical quick connector 9 and the junction box 10 on the carrying support frame 1 are described above.

[0037] The load-bearing support frame 1 includes 2 main load-bearing beams 101, 2 main load-bearing longitudinal beams 102, 1 auxiliary load-bearing beam 103, 1 auxiliary load-bearing longitudinal beam 104, and 4 columns 105 for ensuring the strength of the cooling unit. The main bearing beam 101 and the main bearing longitudinal beam 102 constitute a rectangular support frame for fixing the radiator 3 and the fan box body 5, and the auxiliary bearing beam 103 is fixed between the main bearing longitudinal beams 102 , the auxiliary load-bearing longitudinal beam 104 is fixed between the main load-bearing be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com