Oversized-linear-energy-resistant sintered flux for submerged-arc welding and manufacturing method thereof

A technology of sintered flux and submerged arc welding, applied in welding equipment, welding medium, manufacturing tools, etc., can solve problems such as difficulty in ensuring welding quality, achieve the effect of improving welding efficiency and enhancing the ability to withstand large currents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

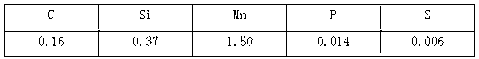

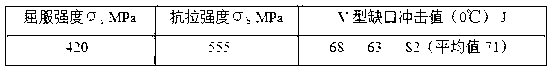

[0031] Using the method of the present invention, 10 kg of sintered flux was prepared in this example. The components of the flux and the mass percentages of each component are: alumina (industrial grade α-type alumina calcined at 1450°C, particle size: 80-100 mesh) 18%, magnesia (fused magnesia with a content of 92%, sulfur and phosphorus ≤ 0.04%, particle size: 80-90 mesh) 22%, natural wollastonite (SiO 2 : 42%, CaO: 47%, sulfur, phosphorus ≤ 0.04%, particle size: 80-90 mesh) 5%, fluorite (CaF 2 : 96%, sulfur, phosphorus ≤ 0.03%, particle size: 80-90 mesh) 11%, silicon micropowder (SiO 2 : 98%, sulfur, phosphorus ≤ 0.03%, particle size: 200-230 mesh) 6%, zircon sand (ZrO 2 : 60%, SiO 2 : 32%, S≤0.03%, P≤0.09%, particle size: 60-100 mesh) 2%, reduced iron powder (Fe: 98%, S≤0.02%, P≤0.02%, hydrogen loss ≤0.5%, particle size : 100-120 mesh) 30%, ferromanganese alloy (Mn: 75%, P≤0.33%, S≤0.03%, particle size: 80-100 mesh) 2.5%, ferrosilicon alloy (Si: 42%, P≤0.04%, S≤0.02%,...

Embodiment 2

[0047] Using the method of the present invention, 10 kg of sintered flux was obtained in this example. The components of the flux and the mass percentages of each component are: alumina (industrial grade α-type alumina calcined at 1500°C, particle size: 100-200 mesh) 18%, magnesia (fused magnesia with a content of 95%, sulfur and phosphorus ≤ 0.04%, particle size: 90-100 mesh) 22%, natural wollastonite (SiO 2 : 45%, CaO: 50%, sulfur, phosphorus ≤ 0.04%, particle size: 90-100 mesh) 5%, fluorite (CaF 2 : 98%, sulfur, phosphorus ≤ 0.03%, particle size: 90-100 mesh) 11%, silicon micropowder (SiO 2 : 99%, sulfur, phosphorus ≤ 0.03%, particle size: 240-250 mesh) 6%, zircon sand (ZrO 2 : 70%, SiO 2 ≤25%, S≤0.03%, P≤0.09%, particle size: 110-120 mesh) 2%, reduced iron powder (Fe: 99%, S≤0.02%, P≤0.02%, hydrogen loss ≤0.5%, particle size : 130-150 mesh) 30%, ferromanganese alloy (Mn: 85%, P≤0.33, S≤0.03%, particle size: 110-120 mesh) 2.5%, ferrosilicon alloy (Si: 47%, P≤0.04%, S ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com