Laminate

A laminate and adhesive layer technology, applied in the direction of layered products, semiconductor devices, electric solid devices, etc., can solve the problems of reduced photoelectric conversion efficiency, poor packaging, and reduced light transmittance of laminates, and achieve photoelectric conversion efficiency Reduction suppression, reduction of transparency reduction, effect of high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

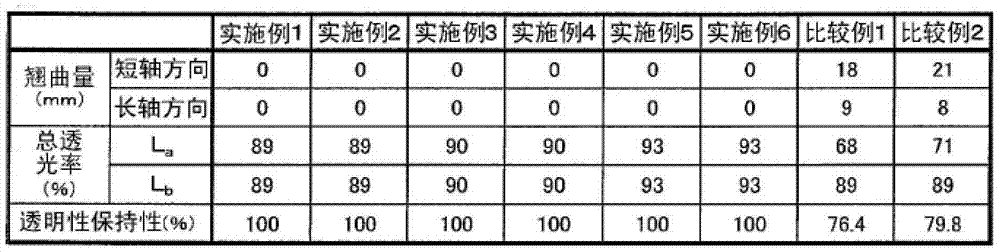

Examples

preparation example 1

[0090] Preparation Example 1 (Preparation of Adhesive Layer (1))

[0091] 69 parts by weight of 2-ethylhexyl acrylate (2EHA), 30 parts by weight of 2-methoxyethyl acrylate (2MEA), 1 part by weight of 4-hydroxybutyl acrylate (4HBA) and 1 part by weight 0.05 parts by weight of the trade name "IRGACURE184" manufactured by Ciba Specialty Chemicals Inc. and 0.05 parts by weight of the trade name "IRGACURE651" manufactured by Ciba Specialty Chemicals Inc. were compounded as a photopolymerization initiator in a mixture of acrylic acid (AA), and then Ultraviolet rays were irradiated until the viscosity (BH viscometer No. 5 spindle, 10 rpm, measurement temperature 30° C.) reached about 20 Pa·s to prepare a prepolymer composition in which a part of the above-mentioned monomer components were polymerized.

[0092] 0.01 parts by weight of 1,3-bis(N,N-diglycidylaminomethyl)cyclohexane [manufactured by Mitsubishi Gas Chemical Co., Ltd., trade name "TETRAD C" was added to 100 parts by weight...

preparation example 2

[0096] Preparation Example 2 (Preparation of Adhesive Layer (2))

[0097] Use 1,6-hexamethylene diisocyanate [manufactured by Asahi Kasei Chemicals Corporation, trade name “DURANATE] instead of 1,3-bis(N,N-diglycidylaminomethyl)cyclohexane [Mitsubishi Gas Chemical Company manufacture, brand name "TETRAD C"], and obtained the adhesive layer (2) (with a separator) in the same manner as in Preparation Example 1.

preparation example 3

[0098] Preparation Example 3 (Preparation of Thermoplastic Resin Layer (1))

[0099] Heat and melt EVA [manufactured by DuPont-Mitsui Polychemicals Co., Ltd., trade name "EVAFLEX EV550", melting point: 89°C] at a temperature of 180°C, and extrude by T-die molding so that the final thickness (adhesive layer thickness) reaches 400 μm, and is dried to form a thermoplastic resin layer (1) with a total light transmittance of 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com