Inductive element and manufacturing method thereof

A technology of inductive components and components, applied in the manufacture of inductors/transformers/magnets, electrical components, transformers/inductor cores, etc., can solve problems such as volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] The invention discloses a laminated inductive element and a manufacturing method thereof. The laminated inductive element can be used to form inductors, antennas, common mode choke coils, transformers and the like.

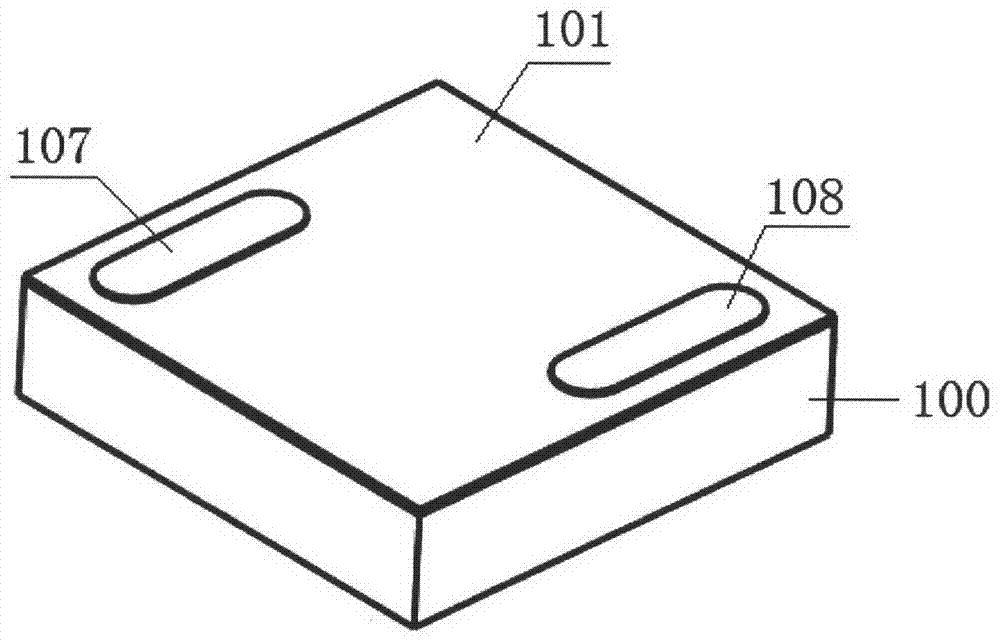

[0099] Figure 1 to Figure 5 is a diagram of an inductor of the first embodiment of the inductive element of the present invention. in, figure 1 is the general structure diagram of the inductor. Seen from the outside, the inductor is a box-shaped structure with a box body 100 and a box cover 101 , and the box cover 101 has two electrodes 107 and 108 . Wherein, the box body 100 and the box cover 101 can be combined to form a closed-circuit magnetic core used in this embodiment.

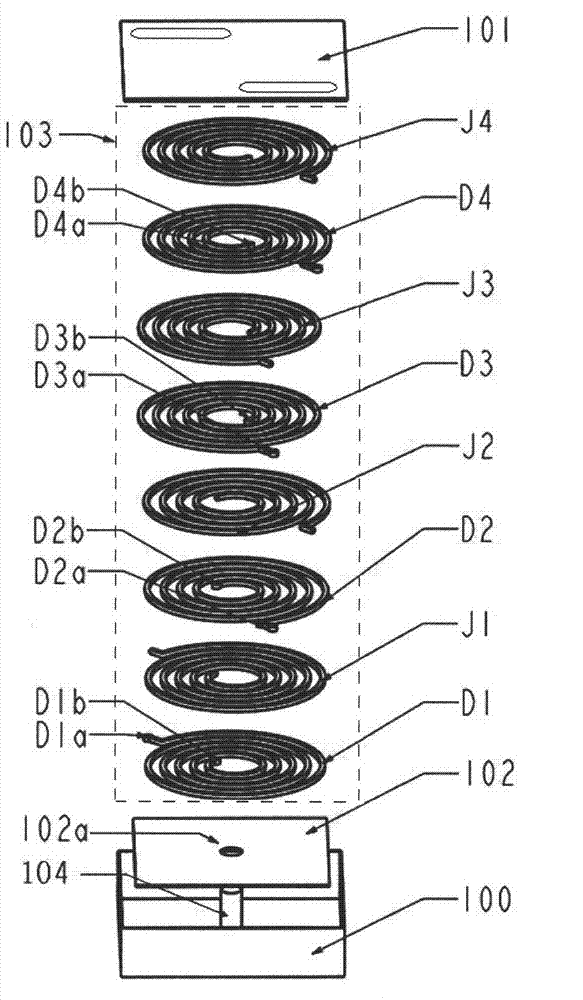

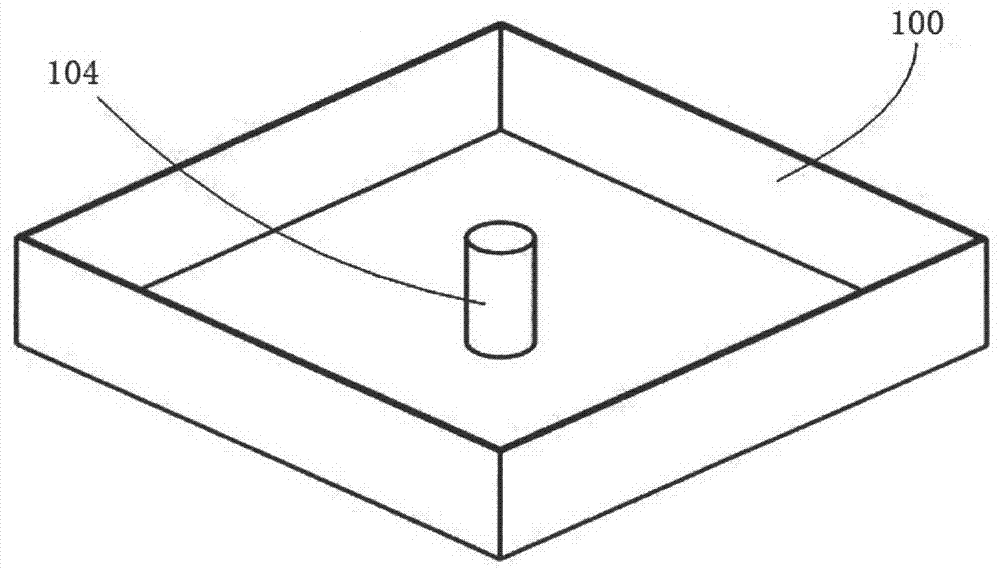

[0100] figure 2 An exploded view of the inductor of the first embodiment is given. The inductor includes a substrate 102, a laminated body 103, and a closed-circuit magnetic core. Wherein, the substrate 102 has a through hole 102a (see Figure 4 ), the central axis of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com