Drying and calcining process and device for coproduction of sulfuric acid and cement from gypsum

A technology of drying device and calcining device, applied in cement production, sulfur compound, clinker production and other directions, can solve the problems of increasing fuel consumption of burning system, increasing the amount of water vapor in the system, reducing the dew point temperature of flue gas, etc. Corrosion risk, simplification of system processes, effect of reducing heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

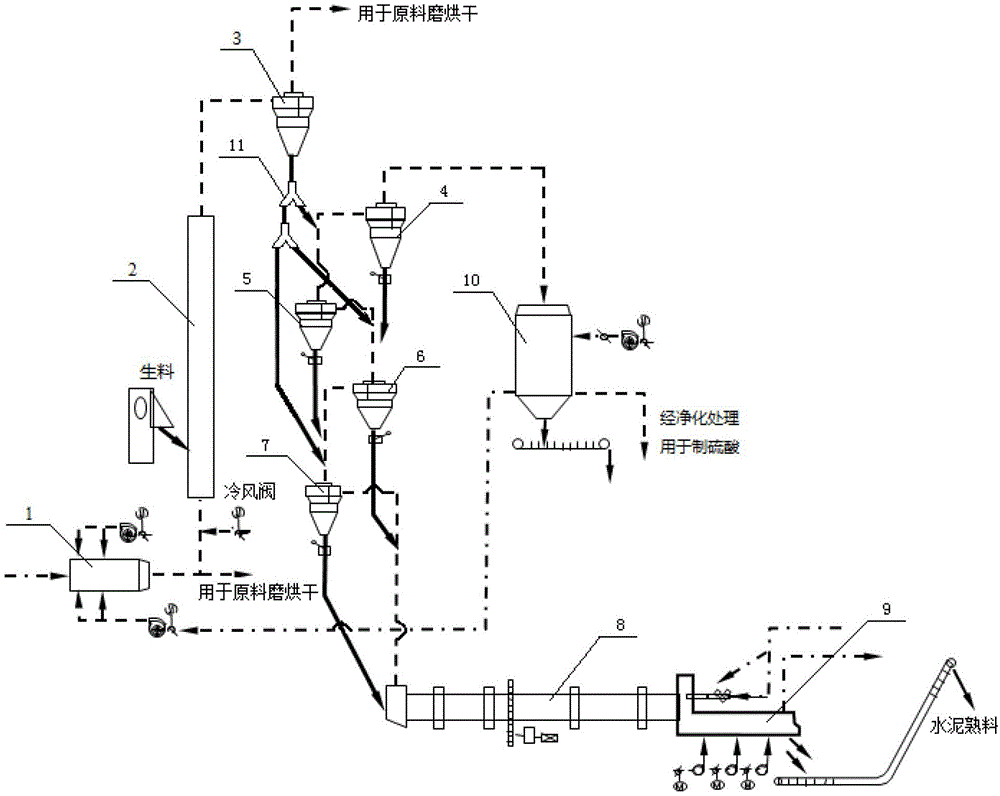

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0022] See figure 1 , a drying and calcining device for sulfuric acid co-production cement from gypsum, including drying and dehydration equipment and a firing system; the firing system includes a preheater system, a rotary kiln 8 and a clinker cooler 9 connected in sequence;

[0023] The preheater system includes 3 to 5 stages of cyclones, the feed port of the primary cyclone 3 is connected to the discharge port of the drying and dehydrating equipment, and the discharge port of the primary cyclone 3 passes through the material distribution valve 11 It is respectively connected with the air inlet pipes of all the cyclones below it, and the air outlet of the first-stage cyclone 3 is connected with the outlet pipe of the drying exhaust gas; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com