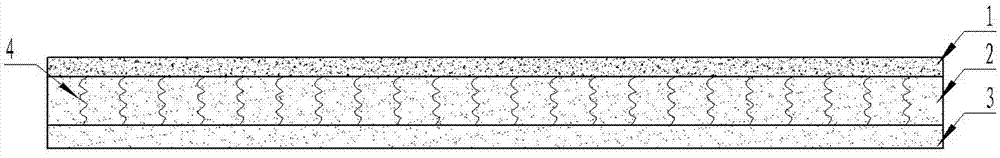

Reinforced cement machine-made board with three-dimensional cavity fiber structure and production method of board

A technology of fiber structure and cement reinforcement, applied in chemical instruments and methods, hydraulic material layered products, layered products, etc., can solve the problems of insignificant mechanical reinforcement effect, product size limitation, low flexural strength, etc. To achieve the effect of flexibility and variety of product forms, increase and service life, and improve durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] 1) Mix 20kg (20%) of cement, 30kg (30%) of sand, 24kg (24%) of glass crumbs, 6kg (6%) of inorganic anti-cracking agent according to the proportion by weight, calcium raw material: magnesium raw material: silicon Aluminum raw material: alumina-based ultra-short fiber: silica-based ultra-short fiber: silica-alumina powder=2.52:0.9:0.18:0.6:1.2:0.6), powdered pigment 4kg (4%), soap-free siloxane Mix 2kg (2%) of non-toxic polypropylene emulsion, 1kg (1%) of naphthalene sulfonate formaldehyde condensate, 3kg (3%) of metakaolin, 2kg (2%) of mineral powder, and 8kg (8%) of water, and mix them evenly into decorative surface mortar.

[0072] 2) At the end of the assembly line, the pallet is placed by the suction cup manipulator, the pallet is transported with the production line, and the PVA coil is laid in front of the cloth outlet as a molding auxiliary material.

[0073] 3) Pump the prepared surface layer mortar to the distribution port and pour it on the pallet. After being...

Embodiment 2

[0083] 1) According to the proportion by weight, 41.4kg (41.4%) of cement, 15kg (15%) of fine stones, 10kg (10%) of ceramic debris, 4kg (4%) of inorganic anti-cracking agent, calcium raw materials: magnesium raw materials : Si-alumina Raw material: Zirconia-based ultra-short fiber: SiC-based ultra-short fiber: Si-alumina powder=1.92:0.24:0.24:0.8:0.4:0.4), liquid pigment 0.1kg (0.1%), soap-free silica Alkane modified styrene-acrylic emulsion 2.5kg (2.5%), sulfonated melamine formaldehyde condensate 1kg (1%), sulfate 1kg (1%), metakaolin 3kg (3%), stone powder 2kg (2%), water 20kg (20%) mixed and stirred evenly to make decorative surface mortar.

[0084] 2) At the end of the assembly line, the pallet is placed by the suction cup manipulator, and the pallet is transported along with the production line, and kraft paper is laid in front of the cloth outlet as a molding auxiliary material.

[0085] 3) Pump the prepared surface layer mortar to the distribution port and pour it on ...

Embodiment 3

[0095] 1) According to the percentage distribution by weight, cement 45kg (45%), metal scraps 15kg (15%), mica fragments 10kg (10%), inorganic anti-cracking agent 5kg (5%), calcium raw materials: magnesium raw materials: Si-alumina raw material: Calcium sulfate-based ultra-short fiber: Zinc oxide-based ultra-short fiber: Si-alumina powder=0.9:0.9:1.2:0.5:1:0.5), liquid pigment 2kg (2%), soap-free siloxane modification Mix 0.1kg (0.1%) of silicone acrylic emulsion, 1kg (1%) of polycarboxylate superplasticizer, 1kg (1%) of calcium chloride, 0.9kg (0.9%) of fly ash, and 20kg (20%) of water, After stirring evenly, it is made into a decorative surface layer mortar.

[0096] 2) At the end of the assembly line, the pallet is placed by the suction cup manipulator, the pallet is transported with the production line, and the PVA coil is laid in front of the cloth outlet as a molding auxiliary material.

[0097] 3) Pump the prepared surface layer mortar to the distribution port and pour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com