Heat pipe air pre-heater capable of preventing dew point corrosion

An air preheater and dew point corrosion technology, applied in indirect heat exchangers, damage protection, heat exchange equipment, etc., can solve the problems of easy dust accumulation, dew point corrosion and pipe burst, achieve low cost, reduce dew point corrosion, The effect of improving heat exchange efficiency and self-cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

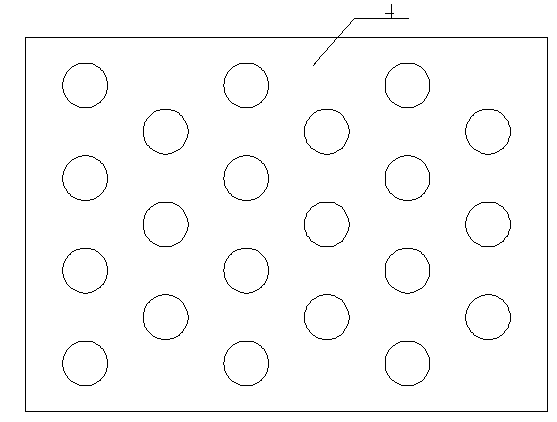

[0020] Such as figure 1 As shown, a heat pipe air preheater for preventing dew point corrosion includes a cuboid box 1, and the box 1 is provided with an upper cold flow chamber 2 and a lower hot flow chamber that separate the inner cavity of the box from each other. The separator 4 of 3 has multiple rows of heat pipes 5 interspersed and welded on the separator 4, and the separator 4 is located in the middle of the heat pipe. The upper sections of all heat pipes 5 are located in the cold flow chamber 2, and the lower sections of the heat pipes 5 are located in the hot flow chamber 3. The outer surfaces of the heat pipes 5 are welded with spiral fins 6 of equal height, and the first two rows of heat pipes near the input port at the left end of the heat flow chamber 3 The total area of the fins 6 of the upper section of 5 is greater than the total area of the fins 6 of the lower section, that is, the pitch of the upper fins 6 is 10mm, and the pitch of the lower fins 6 is 20m...

Embodiment 2

[0026] Compared with Embodiment 1, the difference of this embodiment is that the pitch of the fins 6 on the outer surface of the heat pipe 5 is the same, but the height of the fins 6 is not equal, and the first two rows of heat pipes near the input port at the left end of the heat flow chamber 3 The total area of the fins 6 of the upper section of 5 is greater than that of the lower section, the height of the upper section fins 6 is 30mm, and the height of the lower section fins 6 is 15mm; The area is smaller than the lower section, the height of the lower section fin 6 is 30mm, and the height of the upper section fin 6 is 15mm;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com