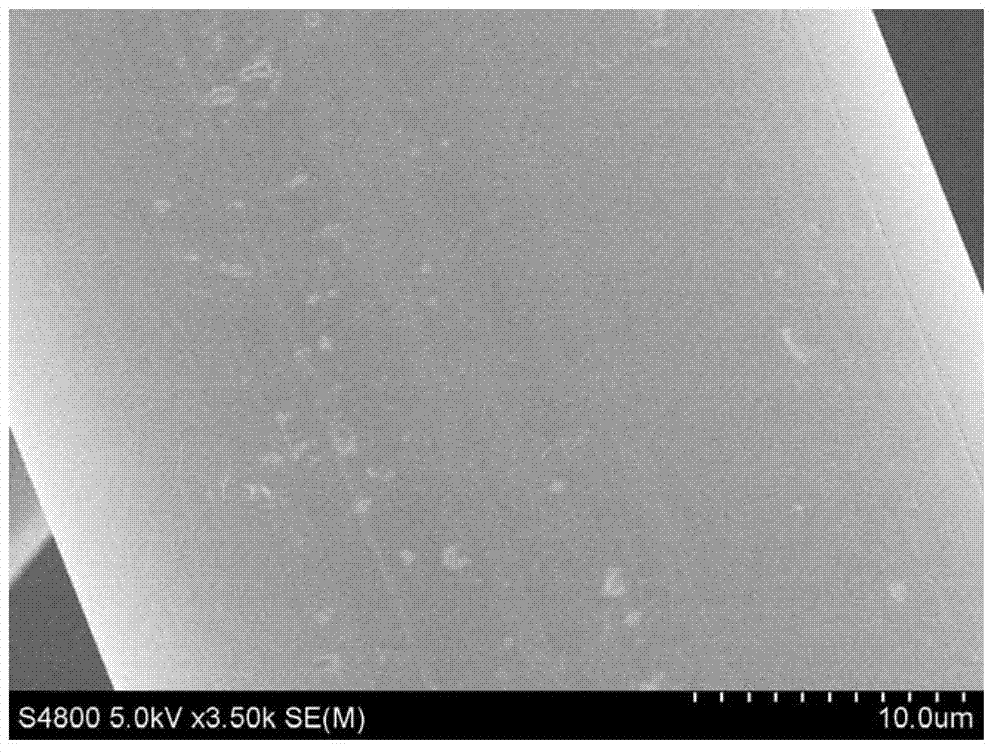

Method for preparing silica fiber and silica microsphere composite super-hydrophobic material

A silicon dioxide and superhydrophobic technology, applied in chemical instruments and methods, and other chemical processes, can solve problems such as poor environmental adaptability, easily damaged structure, and poor stability, and achieve good processability, good spherical shape, and moisture absorption. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

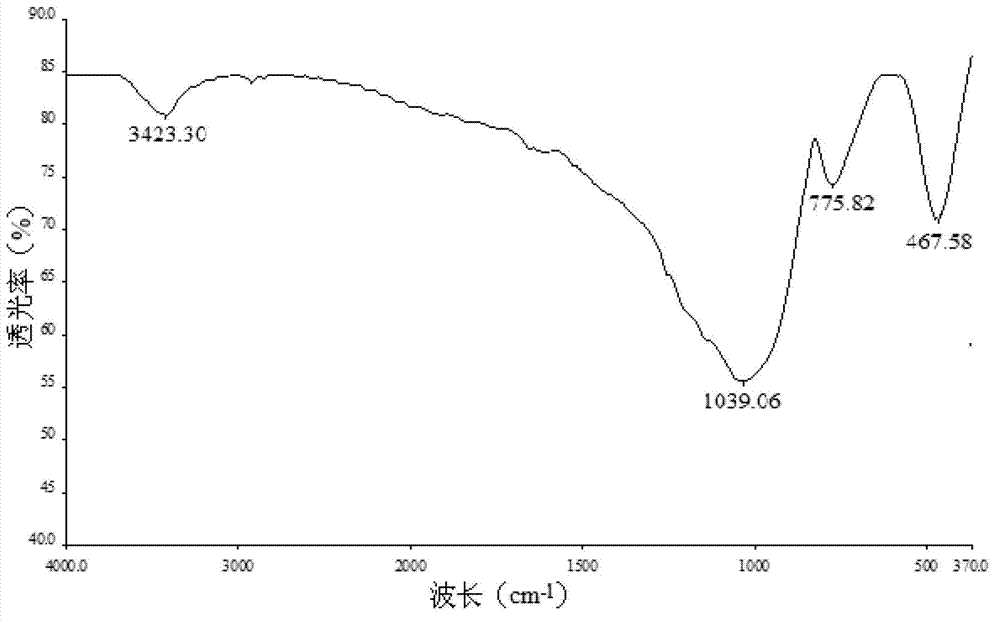

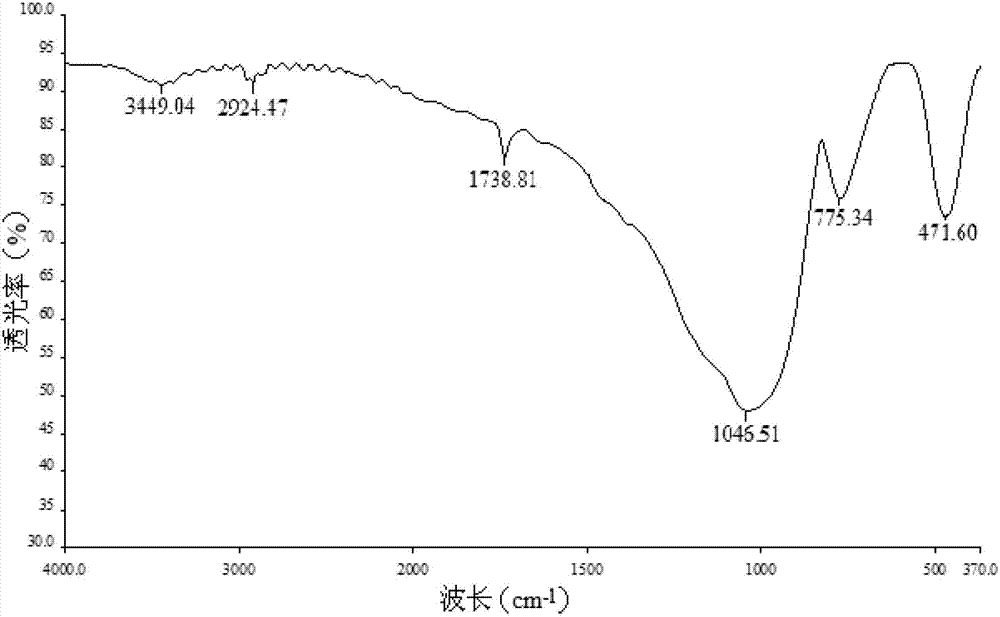

[0019] Specific embodiment one: the preparation method of a kind of silica fiber and silica microsphere composite superhydrophobic material of this embodiment is carried out according to the following steps:

[0020] 1. Clean the silica fiber with hydrochloric acid and deionized water in sequence, then clean the silica fiber with absolute ethanol and deionized water in sequence, repeat the operation in this step for 2 to 4 times, and then dry;

[0021] 2. Submerge the silica fiber after step 1 in the toluene solution of KH-550 for 5h to 7h, then treat it in hydrochloric acid for 0.5h to 1.5h, wash with deionized water and dry to obtain silica fiber; The ratio of the mass of silica fiber obtained in the step 1 to the volume of the toluene solution of KH-550 is 100 mg: (20-100) mL, and the volume fraction of KH-550 in the toluene solution of KH-550 is 1% , wherein the ratio of the mass of silica fiber obtained in step 1 to the volume of hydrochloric acid is 100 mg: (20-100) mL, ...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment differs from Embodiment 1 in that: Step 1 repeats the operation in this step 3 times, and other steps and parameters are the same as Embodiment 1.

specific Embodiment approach 3

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step two, the silica fiber after step one is immersed in the toluene solution of KH-550 for 6h, then treated in hydrochloric acid for 1h, other The steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com