Plant oil benzoxazine copolymer elastomer preparation method

A technology of benzoxazine and elastomer, which is applied in the field of preparation of vegetable oil benzoxazine copolymer elastomer, can solve problems that have not yet been reported on polymer materials, achieve excellent thermal stability, reduce production costs, and structural rigidity strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

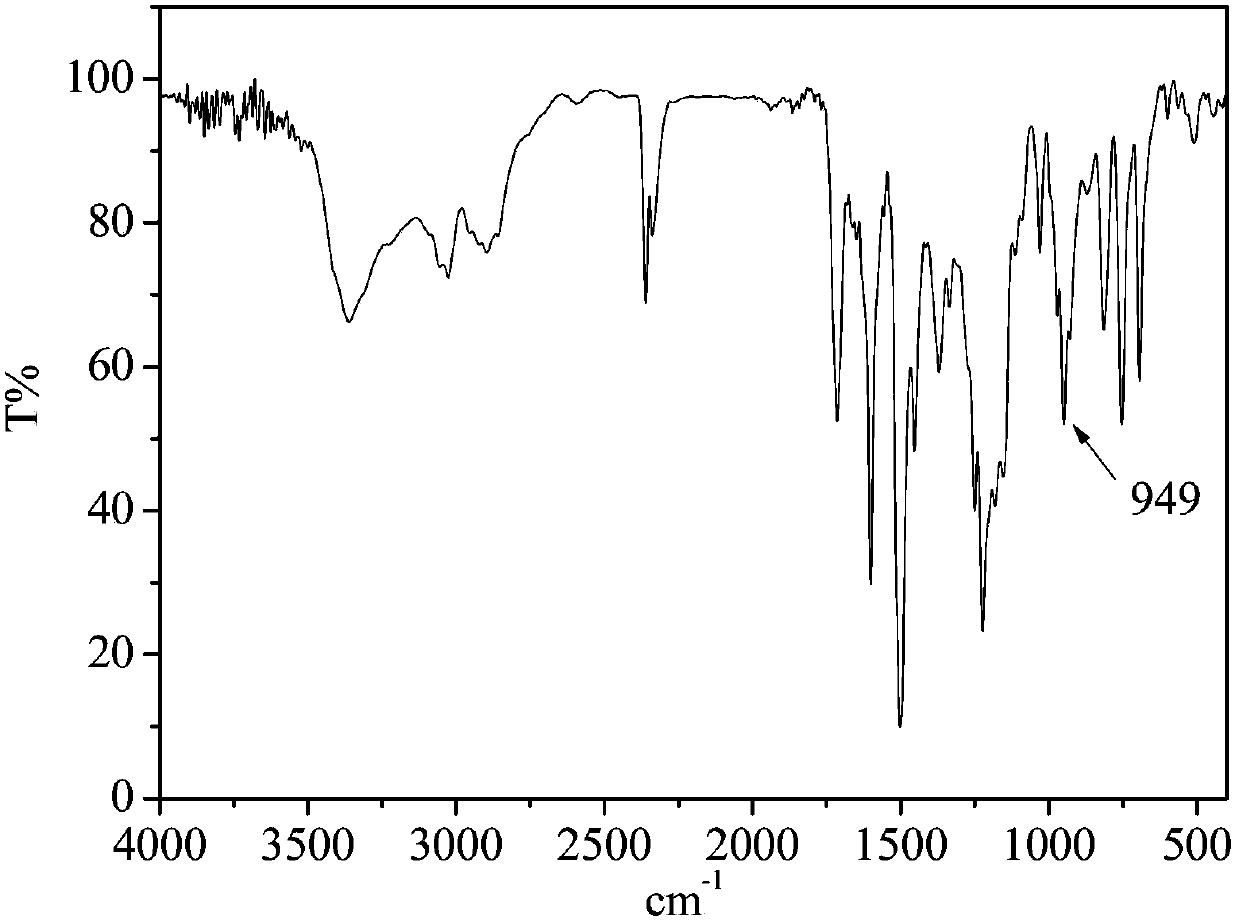

Embodiment 1

[0029] A kind of preparation method of soybean oil benzoxazine copolymer elastomer, comprises the steps:

[0030] (1) Ring-opening addition of part of the epoxy groups of epoxy soybean oil and ethylenediamine to obtain soybean oil-based prepolymer: when the epoxy soybean oil oil bath is heated to 85°C, add ethylenediamine and triethylamine Catalyst, the mass ratio of epoxidized soybean oil, ethylenediamine and triethylamine is 100:6.5:1.0, then the oil temperature is raised to 95°C, and the reaction is stopped after continuing the constant temperature reaction for 3.5 hours.

[0031] (2) Preparation method of amino-containing benzoxazine monomer

[0032] Using trifluoroacetic anhydride (TAFF) as amine protecting agent, a benzoxazine blocker retaining amino group was synthesized. The reaction equation is as follows:

[0033]

[0034] Dissolve 4-aminophenol in tetrahydrofuran, put it in an ice-water bath and stir for 30 minutes, add trifluoroacetic anhydride dropwise, the m...

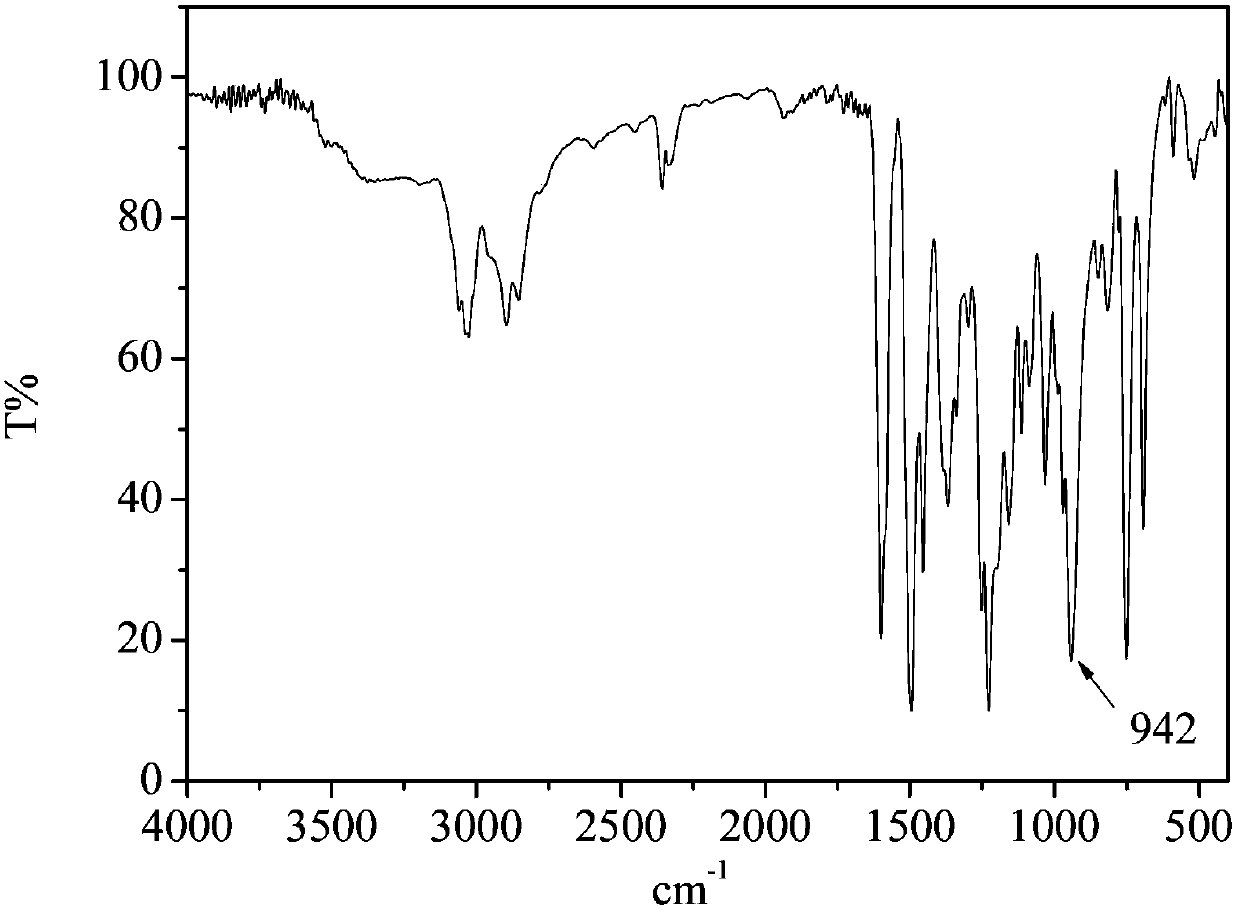

Embodiment 2

[0045] (1) Ring-opening addition of some epoxy groups of epoxy soybean oil and triethylenetetramine to obtain soybean oil-based prepolymer. When the epoxidized soybean oil oil bath is heated to 120 DEG C, add triethylenetetramine and trimethylamine catalyst, the mass ratio of epoxidized soybean oil: triethylenetetramine: trimethylamine is 100: 2.5: 0.2, then the oil temperature rises Up to 125°C, continue the constant temperature reaction for 1.5 hours and then stop the reaction

[0046] (2) The preparation method of amino-containing benzoxazine.

[0047] Dissolve 2-aminophenol in tetrahydrofuran, put it in an ice-water bath and stir for 15 minutes, then add trifluoroacetic anhydride dropwise, 2-aminophenol: trifluoroacetic anhydride in a mass ratio of 100:250, and control the rate of addition in 60 minutes. The tetrahydrofuran was removed by evaporation, and ethyl acetate was added to dissolve the product, washed three times with saturated brine, dried by adding anhydrous so...

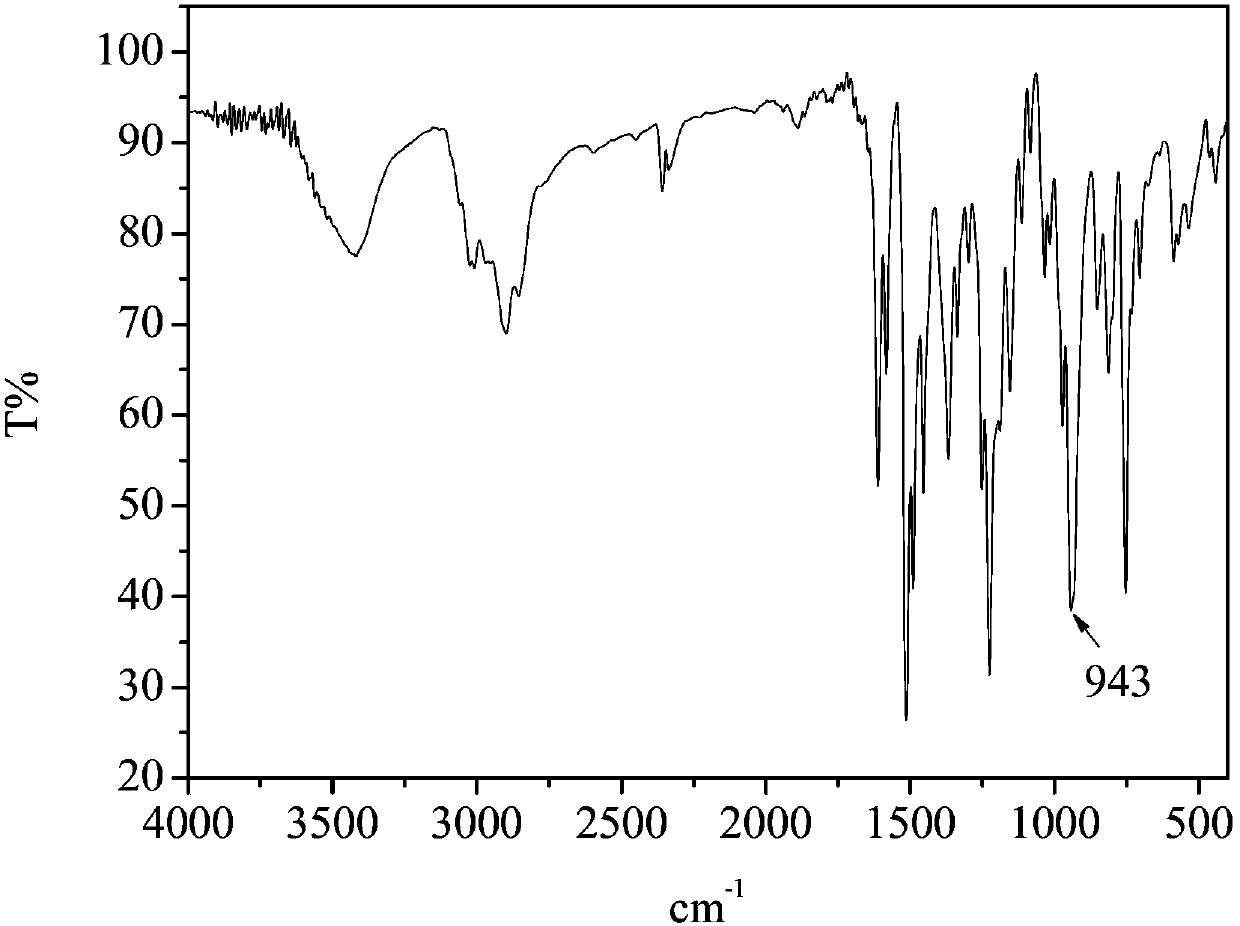

Embodiment 3

[0056] (1) Ring-opening addition of some epoxy groups of epoxy soybean oil and piperazine to obtain soybean oil-based prepolymer. When epoxy soybean oil oil bath is heated to 85 ℃, add piperazine and triethylamine catalyst, epoxy soybean oil: piperazine: the mass ratio of triethylamine is 100: 8.5: 1.0, then oil temperature is raised to 95°C, continue the constant temperature reaction for 3.5 hours, then stop the reaction.

[0057] (2) The preparation method of amino-containing benzoxazine.

[0058] Dissolve 3-aminophenol in tetrahydrofuran, put it in an ice-water bath and stir for 30 minutes, then add trifluoroacetic anhydride dropwise, 3-aminophenol: trifluoroacetic anhydride in a mass ratio of 100:250, and control the rate of addition to finish dropping in 30 minutes. The tetrahydrofuran was removed by evaporation, and ethyl acetate was added to dissolve the product, washed three times with saturated brine, dried by adding anhydrous sodium sulfate, filtered, and the solven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com