rcpp film for packaging and preparation method thereof

A film and intermediate layer technology, applied in the field of packaging materials, can solve the problems of poor heat sealability and impact resistance, too hard texture, etc., and achieve the effect of improving stiffness, good physical and mechanical properties, and good foreign matter inclusion heat sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of RCPP film includes the following processes in sequence: extrusion process, cooling and shaping process, thickness measurement process, deflection process, corona process, trimming and winding process.

[0032] a. In the extrusion process: respectively add corona layer resin raw materials, intermediate layer resin raw materials and heat-sealing layer resin raw materials to the three extruder hoppers of the co-extrusion casting machine; the extrusion process adopts three-stage heating, one The temperature of the first-stage extruder is: 210°C, the temperature of the second-stage extruder: 225°C, the temperature of the third-stage extruder: 230°C; the temperature of the die head: 225°C.

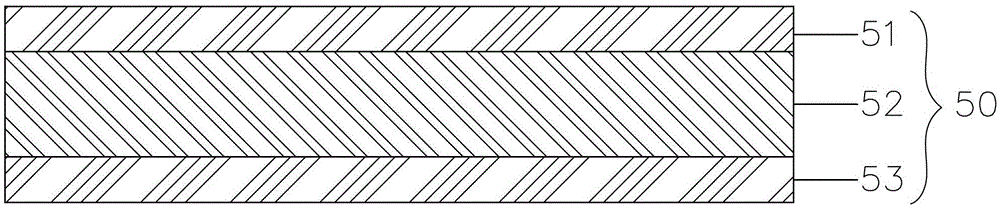

[0033] The corona layer 51 is composed of F354NV (block copolymer polypropylene).

[0034] The middle layer 52 is composed of F354NV (block copolymerized polypropylene) and G2806GO (polystyrene-polyethylene / polybutylene-polystyrene), and the weight ratio of F354NV and G...

Embodiment 2

[0044] The preparation of RCPP film includes the following processes in sequence: extrusion process, cooling and shaping process, thickness measurement process, deflection process, corona process, trimming and winding process.

[0045] a. In the extrusion process: respectively add corona layer resin raw materials, intermediate layer resin raw materials and heat-sealing layer resin raw materials to the three extruder hoppers of the co-extrusion casting machine; the extrusion process adopts three-stage heating, one The temperature of the first-stage extruder is: 210°C, the temperature of the second-stage extruder: 225°C, the temperature of the third-stage extruder: 230°C; the temperature of the die head: 225°C.

[0046] The corona layer 51 is composed of F354NV (block copolymer polypropylene).

[0047] The middle layer 52 is composed of F354NV (block copolymerized polypropylene) and G2806GO (polystyrene-polyethylene / polybutylene-polystyrene), and the weight ratio of F354NV and G28...

Embodiment 3

[0057] The preparation of RCPP film includes the following processes in sequence: extrusion process, cooling and shaping process, thickness measurement process, deflection process, corona process, trimming and winding process.

[0058] a. In the extrusion process: add corona layer resin raw materials, intermediate layer resin raw materials and heat-sealing layer resin raw materials to the three barrels of the co-extrusion machine respectively; the extrusion process uses three-stage heating, and the first-stage extruder temperature For: 210°C, second-stage extruder temperature: 225°C, third-stage extruder temperature: 230°C; die head temperature: 225°C.

[0059] The corona layer 51 is composed of F354NV (block copolymer polypropylene).

[0060] The middle layer 52 is composed of F354NV (block copolymerized polypropylene) and G2806GO (polystyrene-polyethylene / polybutylene-polystyrene), and the weight ratio of F354NV and G2806GO is 82:18.

[0061] The heat-sealing layer 53 is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com