Collagen/chitosan micro-nano fiber composite hemostatic membrane material and preparation method thereof

A fiber composite and chitosan technology, applied in the fields of medical science, absorbent pads, bandages, etc., can solve the problems of insufficient mechanical properties of collagen-based hemostatic agents, unable to meet market requirements, insufficient purity of type I collagen, etc. Degradability, Wound Healing Promotion, Good Biocompatibility Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

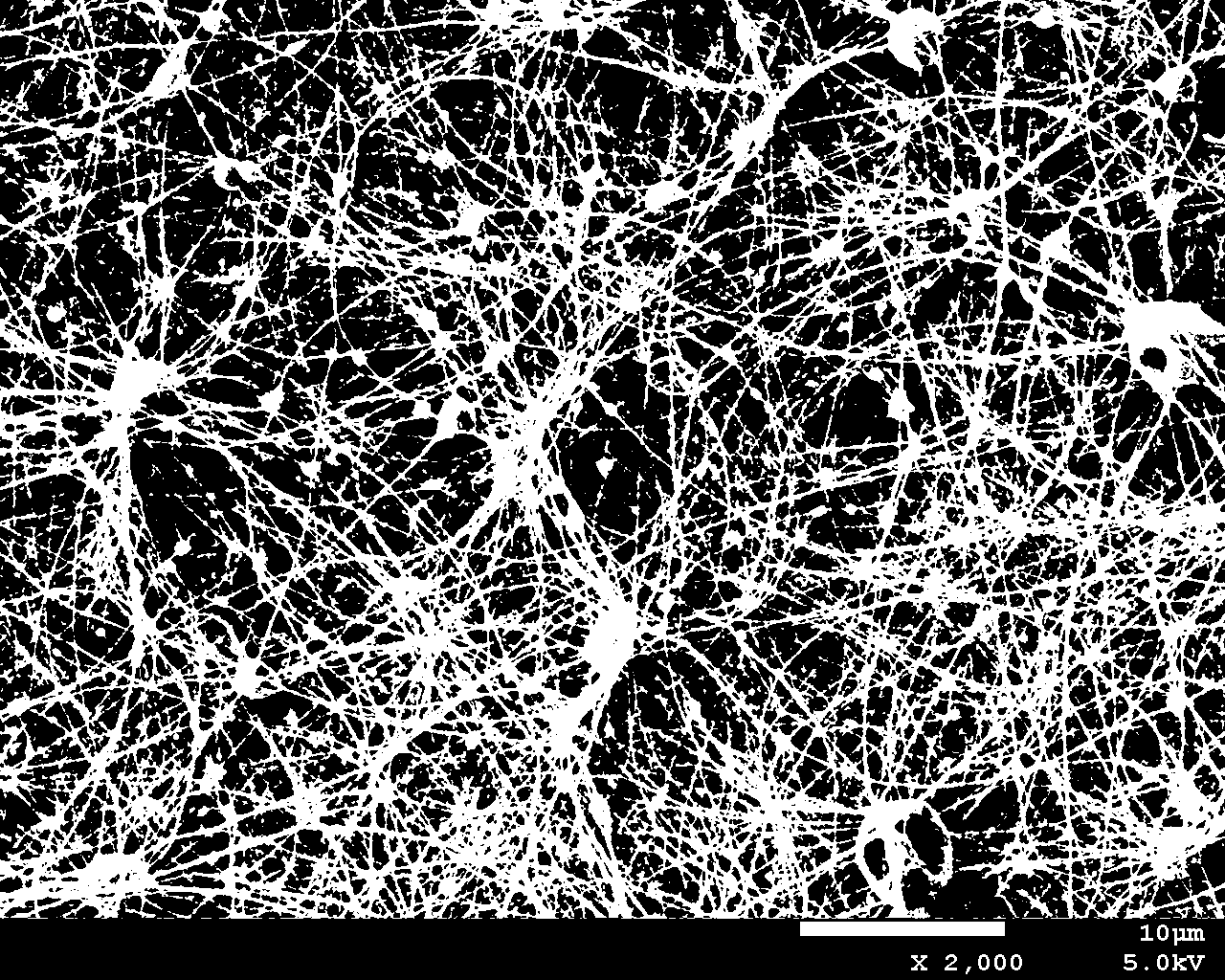

Image

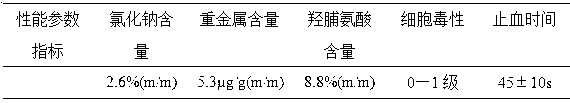

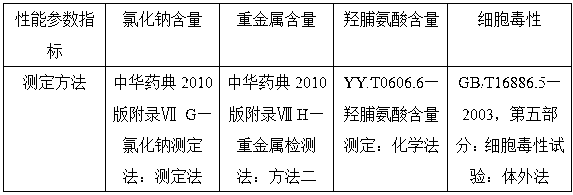

Examples

Embodiment 1

[0029](1) Type I collagen extraction: Take 10 parts by weight of medical biological skin, cut it into small pieces of 0.5cm×0.5cm, wash it with ultrapure water for 5 times, and then soak it in 0.05mol / L Tris, 1mol / L L NaCl, in a Tris-NaCl buffer solution with a pH of 7.5, place it in an ultrasonic cleaner with a frequency of 20kHz, and act for 2 hours; pour off the buffer solution, rinse the skin twice with distilled water; add 30 times of 0.5M acetic acid solution, soaked for 2 hours, crushed and homogenized with a homogenizer at a constant temperature of 4°C, and then transferred to a reaction kettle, adding 0.2 parts by weight of pepsin; under ultrasonic conditions with a frequency of 30kHz, slowly stirred at 4°C Enzyme hydrolysis for 36 hours, and act for 1 hour every 3 hours; after the reaction is completed, stop stirring, filter the reaction solution, adjust the pH of the filtrate to 7.0, add ammonium sulfate powder with a final concentration of 1.5mol / L, and let it stand...

Embodiment 2

[0036] (1) Type I collagen extraction: Take 10 parts by weight of medical biological skin, cut it into small pieces of 0.5cm×0.5cm, wash it with ultrapure water for 5 times, and then soak it in 0.05mol / L Tris, 1mol / L L NaCl, in a Tris-NaCl buffer solution with a pH of 7.5, place it in an ultrasonic cleaner with a frequency of 30 kHz, and act for 2 hours; pour off the buffer solution, rinse the skin twice with distilled water; add 40 times of 0.5M acetic acid Solution, soaked for 2 hours, crushed and homogenized with a homogenizer at a constant temperature of 4°C, then transferred to a reaction kettle, added 0.2 parts by weight of pepsin, and slowly stirred the enzyme at 4°C under ultrasonic conditions with a frequency of 30kHz Solution for 24 hours, every 3 hours for 1 hour. After the reaction is completed, stop stirring, filter the reaction solution with suction, adjust the pH of the filtrate to 7.5, add ammonium sulfate powder with a final concentration of 1.5mol / L, and let ...

Embodiment 3

[0043] (1) Type I collagen extraction: Take 10 parts by weight of medical biological skin, cut it into small pieces of 0.5cm×0.5cm, wash it with ultrapure water for 5 times, and then soak it in 0.05mol / L Tris, 1mol / L L NaCl, in a Tris-NaCl buffer solution with a pH of 7.5, place it in an ultrasonic cleaner with a frequency of 30 kHz, and act for 2 hours; pour off the buffer solution, rinse the skin twice with distilled water; add 50 times of 0.5M acetic acid solution, soaked for 2 hours, crushed and homogenized with a homogenizer at a constant temperature of 4°C, and then transferred to a reaction kettle, adding 0.2 parts by weight of pepsin; under the condition of ultrasonic waves with a frequency of 20kHz, the enzyme was slowly stirred at 4°C Decompose for 36 hours, and act for 1 hour every 3 hours; after the reaction is completed, stop stirring, filter the reaction solution with suction, adjust the pH of the filtrate to 7.3, add ammonium sulfate powder with a final concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com