A kind of preparation method of polypropylene-based bamboo-plastic foam composite material

A polypropylene plastic and polypropylene-based technology, which is applied in the field of composite materials and forestry engineering, can solve the problems of difficult polypropylene foaming, limited application fields, high density, etc., and achieve good market space, development prospects, and cell shape good, low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

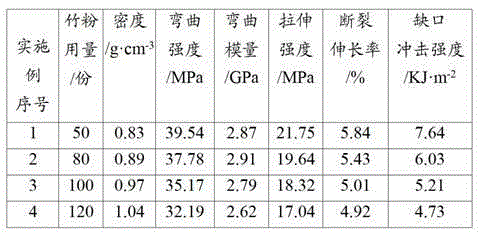

Examples

Embodiment 1

[0014] A kind of preparation method of polypropylene-based bamboo-plastic foam composite material of the present invention, comprises the following steps:

[0015] (1) According to the mass ratio, polypropylene PP 1 30 parts, cross-linking agent 1,3 (1,4)-bis(tert-butylperoxyisopropyl) benzene (BIPB) 2 parts, auxiliary cross-linking agent triallyl isocyanurate (TAIC) 1.5 1 part, 1 part of foaming agent azodicarbonamide (AC) and 0.08 parts of a mixture of nano-zinc oxide and calcium stearate in a mass ratio of 1:1 as a foaming aid, placed in a torque rheometer The foaming masterbatch is obtained by medium extrusion, the temperature of the three zones of the extruder is 170°C, and the rotor speed is 20r / min;

[0016] (2) Dry the bamboo powder at 105°C for 10 hours. Polypropylene PP 2 70 parts, bamboo powder 50 parts, lubricant liquid paraffin 1 part, antioxidant hindered phenolic antioxidant 1010 / phosphite antioxidant 168 compound (B225) 3 parts, anti-ultraviolet agent hinder...

Embodiment 2

[0019] A preparation method of polypropylene-based bamboo-plastic foam composite material, comprising the following steps:

[0020] (1) According to the mass ratio, polypropylene PP 1 30 parts, 1 part of crosslinking agent 1,3(1,4)-bis(tert-butylperoxyisopropyl)benzene (BIPB), 2 parts of auxiliary crosslinking agent divinylbenzene (DVB), foaming agent 1.5 parts of azodicarbonamide (AC) and 0.2 parts of a foaming aid (a mixture of nanometer zinc oxide and zinc stearate at a mass ratio of 1:1), placed in a torque rheometer and extruded to obtain foaming For masterbatch, the temperature in the three zones of the extruder is 170°C, and the rotor speed is 30r / min;

[0021] (2) Dry the bamboo powder at 105°C for 10 hours. Polypropylene PP 2 70 parts, 80 parts of bamboo powder, lubricant (a mixture of stearic acid and calcium stearate in a mass ratio of 1:1) 1 part, antioxidant hindered phenolic antioxidant 1010 / phosphite antioxidant 168 compound 2 parts of compound (B225), 3 par...

Embodiment 3

[0024] A preparation method of polypropylene-based bamboo-plastic foam composite material, comprising the following steps:

[0025] (1) According to the mass ratio, polypropylene PP 1 30 parts, 1 part of crosslinking agent 1,3(1,4)-bis(tert-butylperoxyisopropyl)benzene (BIPB), 3 parts of pentaerythritol triacrylate (SR444) as a crosslinking agent, foaming agent 2 parts of azodicarbonamide (AC) and 1 part of nano-zinc oxide as a foaming aid are placed in a torque rheometer to extrude a foaming masterbatch. The temperature in the three zones of the extruder is 170°C, and the rotor The speed is 25r / min;

[0026] (2) Dry the bamboo powder at 105°C for 10 hours. Polypropylene PP 2 70 parts, bamboo powder 100 parts, lubricant epoxy soybean oil 2.5 parts, antioxidant hindered phenolic antioxidant 1010 / phosphite antioxidant 168 compound (B225) 2 parts, anti-ultraviolet agent 2-hydroxyl-4 - 2 parts of n-octyloxybenzophenone (UV531) and 9 parts of interface compatibilizer maleic anh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com